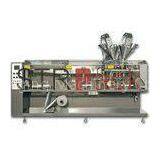

Modified Atmosphere Horizontal Packaging Machine for Beverage Cosmetic

Certification:CE

Quick Detail:

STH-180 Automatic Horizontal Packaging Machine contains motor film releasing, film forming, bottom sealing, vertical sealing, pouch pulling - cutting - opening - filling - transferring - top sealing. At last, the sealed pouch will be manually put into boxes or cartons. The machine has beautiful appearance, with organic glass cover can help to prevent the flowing of dust which is more environmental-friendly. Pouch making, sealing and filling are relatively independent system. The two systems are connected by mechanical connection and PLC. Therefore, suitable for different packaging material and pouch sizes. Finished product sealing system uses hot seal packaging material to go on automatic pouch making, and so on. Pouches are flat bags of 3-side seal or 4-side seal. Selecting different filler can package different products.

Pouch making, sealing and filling are relatively independent system. The two systems are connected by mechanical connection and PLC. Therefore, suitable for different packaging material and pouch sizes. Finished product sealing system uses hot seal packaging material to go on automatic pouch making, and so on. Pouches are flat bags of 3-side seal or 4-side seal. Selecting different filler can package different products.

Description:

Filling system of Power A film reel auto-alignment shaft Two set of horizontal sealing unit Two set of vertical sealing unit Initiative film shaft An independent bag former A 3-side and 4-side sealing device A pair of scissors A tearing notch cutter An automatic material-level control system A MITSUBISHI PLC tracking control system A MITSUBISHI touch-control operation system A 10-digit press printer A product outlet system An operation manual in EnglishSpecifications:

|

Model |

STH-180 |

|

Pouch Width |

60mm-180mm (Single pouch at a time) |

|

60mm-90mm (Double pouch at a time) |

|

|

Pouch Length |

80mm-225mm |

|

Max Volume |

400ml |

|

Speed |

50-80 pouch/min (Single pouch at a time) |

|

100-160 pouch/min(Double pouch at a time) |

|

|

Packaging Film: |

Complex film |

|

Material to Be Packaged: |

Power |

|

Accuracy |

<±1% |

|

Reel |

500mm |

|

Electricity Consumption |

5KW |

|

Power supply |

380V 50HZ 3P |

|

Air Consumption |

0.7m3/min |

|

Weight |

1100KG |

|

Size (L×W×H) |

3560mm×970mm×2150mm |

Competitive Advantage:

|

1 |

Our machines are reputed for high accuracy. |

|

2 |

Unique with respect to container interchangeability with minimum size parts. |

|

3 |

Quick change over, minimum down time and highly operator friendly. |

|

4 |

Custom built for the Food and packaging Processing Industry. |

|

5 |

Microprocessor controls with human – machine interface and touch screen controls. |

|

6 |

Can achieve filling speeds upto 300 containers per minute. |

Picture show:

Send Inquiry to This Supplier

You May Also Like

-

Sedan Vehicle CoverNegotiableMOQ: 1 Piece

-

Refrigerant gas R410aNegotiableMOQ: 1 Piece

-

FEIKU Electric Mountain BikeNegotiableMOQ: 1 Piece

-

Blue GraniteNegotiableMOQ: 1 Piece

-

Medical Device MachiningNegotiableMOQ: 1 Piece

-

Men\'\'s Leather Jackets With Button ClosedNegotiableMOQ: 1 Piece

-

Military ProductsNegotiableMOQ: 1 Piece

-

Bench ArmNegotiableMOQ: 1 Ton

-

Birch Bed Slats King Bed Slats Wood Round BedsUS$ 400 - 600MOQ: 1 Meter

-

Paulownia Drawer Sides With Groove PanelUS$ 450 - 475MOQ: 5 Cubic Meters