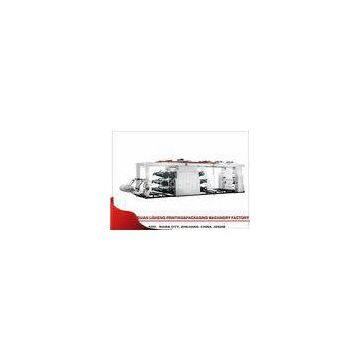

Unwind / Rewind Unit Flexographic Printing Machine for Both Side Paper Cup / Roll Paper

Certification:CE

Unwind / Rewind Unit Flexographic Printing Machine for Both Side Paper Cup / Roll Paper

Specifications:

|

Model |

YTB 1000mm |

|

Max. print material width |

10 50mm |

|

Printing width |

9 60mm |

|

Printing material |

Paper: 50 ~ 35 0g/m2 |

|

Printing color |

6 color (6+0) |

|

Printing length |

7.5\"~ 5 0\"(190mm~1 5 00mm) |

|

M e ch a nical speed |

9 0m/min |

|

Printing speed |

1 0m- 80m/min |

|

Register precision |

Longitude:±0.25mm Transverse:±0.25mm |

|

Rewinder/Unwinder DIA |

Φ 12 00mm (unwinding) |

|

Printing plate lifting system |

Auto Hydraulic cylinder control printing roll up and down |

|

EPC system: |

Edge Position Controller, 1 PC |

|

Tension system |

Automatic tension control for unwinding 1 PCS |

|

Unwinding loading and rewinding unloading way |

By air shaft , with 10 kg magnetic 2 pcs |

|

Printing Pressure |

M echanical adjust |

|

Anilxo roll |

Standard metal anilxo roll (1 0 0-300PLI) blade |

|

Master motor |

3.7Kw TAIWAN BRAND |

|

Drying way |

Electrical heat drying |

|

Drying power |

24 kw |

|

Blower of nature wind |

0.95 Kw x 6 pcs |

|

Inking motor |

Taiwan brand |

|

Master frequency converter |

3.7 kw |

|

Master power |

32 Kw |

|

Dimension(L×W×H) |

5.4 ×2. 4× 3.2 m |

High Speed Six Color Non Woven Bag Flexographic Printing Machine

Competitive Advantage

1. Low speed and full load startup; stable running by tension control when increasing and decreasing speed;noise is decreased

2. Aluminum roller adopts the Japan semi-sealing small bearing; flinty oxidation, static and dynamic balancing treatments are conducted; low resistance and small flop.

3. The special made modulus angular gears adopted; accurate printing size and full printing specifications

( 6.35mm is a spec)

4. With single doctor blade and circulating pump

5. The grouped and controlled bottom roller processed with Germany particular steel materials processed with special techniques and electrically gilded with 0.1mm hard chromium protective layers

6. With hard chroming anilox roll

7. The machine use hydraulic printing-roll loading system which can automatically load printing rolls and run inks after the machine alarm working signal.

8. Good quality printing

9. Brilliance color appearance.

10. The operation is easier and more convenient,the register is more accurate,and the lifespan is also longer

Printing Effect :

Send Inquiry to This Supplier

You May Also Like

-

Printing Booksand Periodicals MagazineNegotiableMOQ: 1 Set

-

Different 3D Printers for Shoes, Dental Model Machine Digital PrinterNegotiableMOQ: 1 Set

-

FAST Shipping Creality Newest Affordable CP-01 Three-in-one Modular 3D Printer+CNC Engraving Machine+Laser Engraving MachineNegotiableMOQ: 1

-

Holographic Sticker Printer Label Full Color Printing Label PrinterUS$ 20,000 - 50,000MOQ: 1 Set

-

Heat Transfer MachineNegotiableMOQ: 1 Set

-

Air Operate Heat Press Machine With CE CertificateNegotiableMOQ: 1 Set

-

Economic&high Quality Bottle Date PrinterUS$ 1 - 4,000MOQ: 1 Set

-

Fruit Printing MachineUS$ 700 - 1,200MOQ: 1 Set

-

2015 Hot Sale of Chinese Wall Inkjet PrinterUS$ 800 - 80,000MOQ: 1 Set

-

High Accuracy Sheet Metal Laser Cutting Machine 700W Industrial Laser CuttersUS$ 30000 - 100000MOQ: 1 Set