Precision CNC Machining Services Lost Wax Investment Casting Process

Certification:ISO9001: 2000

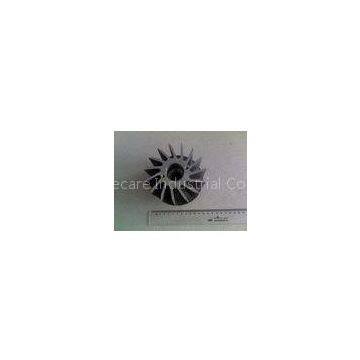

CE Certification Investment Casting Part CNC Machining Parts (SSC-14)

Quick Detail:

| Item | Description | The contents |

Investment casting parts |

Model | SSC-14 |

| Molding technics | Investment casting | |

| Material | A380 | |

| Dimension | ||

| The weight | ||

| Surface treatment | electroplate |

Description:

All of our aluminum alloy castings are produce by the use the precision investment casting process, or lost wax process. We can produce intricate detail that many other foundries are unable to produce. All our aluminum alloy casting molds are built exclusively by hand.

1, The investment casting include shell process (Colloidal Silica process) and the water glass process. A wide range of alloys is available for investment casting. They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys.

2, Investment casting shell process can range from a weight of just a few ounces to approximately 100 pounds(45Kg). Water glass process of investment castings may range in weight from several ounces to approximately 200 pounds(90Kg).

3, Surface treatment of investment casting parts: Heat treatment, machining, polishing, chrome/zinc/nickel plating, etc. A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

4, These parts are used in machine assembly, valve&pump parts, auto&motorcycle parts, train&railway parts, marine hardware, construction hardware, electrical, furniture, etc.

5, Investment casting parts weight: 0.2kg-500kg; Standard of investment casting parts: AISI, ASTM, DIN, GB, BS, JIS, NF, AAR; Quality system certificate for investment casting: ISO9001: 2000

Specifications:

| Material available | Carbon steel, Stainless steel, spring steel, Bronze, brass, copper alloy, aluminum alloy, tinplate, nickel silver, plastic |

| Surface treatment available | Zinc/Nickel/Chrome Plating(color or natural), Galvanization, Anodizing, Hard Anodizing, Oil Spraying, Powder Coating, Polishing, Passivate, Brush, Wire drawing, etc. |

| Manufacturing Methods |

Investment Casting, Die Casting, Sand Casting, Stamping, CNC Machining, Forging, |

| Specification | OEM & make per customer\' s drawing or sample |

| Package | According to customer\' s requirement; |

| Tolerance | CNC machining parts: 0.002 |

| Service available | We supply pre-production samples for customer final confirmation before mass production; |

| Certificate | ISO9001: 2000 |

Send Inquiry to This Supplier

You May Also Like

-

Hot Sales!!!Transistor 2N5434 MOT,New and OrignalNegotiableMOQ: 100 Pieces

-

MMBT2907 2F 0.6A/40V SOT23 SMD Triode TransistorUS$ 0.5 - 1.8MOQ: 100 Pieces

-

RA45H7687M1 RF MOSFET ModuleUS$ 2 - 3MOQ: 1 Piece

-

SOT-23 Bipolar Transistors MMBT3904US$ 0.01 - 0.1MOQ: 3000 Pieces

-

Original Transistor 1MI100H-025US$ 1 - 98MOQ: 1 Piece

-

Healthcare Touch Screen Kiosks In Medical Facilities TSK8010NegotiableMOQ: 1 Piece

-

Custom RGB Flat Panel Video Outdoor Led ScreensNegotiableMOQ: 1 Piece

-

Titanium Precision Machined Parts For Laboratory Equipments , Experimental InstrumentsNegotiableMOQ: 1 Piece

-

Touch Screen Kiosks , Coffee Internet TFT LCD Display TSK8015NegotiableMOQ: 1 Piece

-

Round Ring Flat Surface Temperature Measurement Probe 3950 For Bread Processing MachineNegotiableMOQ: 1 Piece