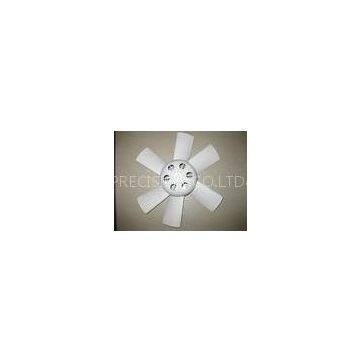

Precise Rubber Injection Mold , Custom Plastic Injection Moulding for Electronic Parts

Certification:ISO9001:2008

Precise Rubber Injection Mold, Custom Plastic Injection Moulding for Electronic Parts

Description:

|

Material: |

Rubber/ABS/PP/PE/PS/POM/PA6/PU/PMMA etc. |

|

Size: |

Customized size |

|

Color: |

Any colors |

|

MOQ: |

Negotiable |

|

Application: |

Electronics; Medical device; Household appliance; Security products; Vending Machine, etc. |

|

Package: |

Inner is pp bag, outer is paper carton, or customized. |

|

Material: |

Rubber/ABS/PP/PE/PS/POM/PA6/PU/PMMA etc. |

|

Size: |

Customized size |

|

Color: |

Any colors |

|

MOQ: |

Negotiable |

|

Application: |

Electronics; Medical device; Household appliance; Security products; Vending Machine, etc. |

|

Package: |

Inner is pp bag, outer is paper carton, or customized. |

Applications:

This product will be widely used on the electronic product industry, it is a very precise mould and the struction is complicated, many slides and inserts need to be designed in the mould.

Specifications:

1.ROHS CE UL standards

2.ISO9001:2008 QMS

3.OEM Plastic material: ABS

4.Mould cavity: Single/Multi

5.Mould life: 500K shots

6.Molding Type: Plastic injection mould production.

Competitive Advantage:

1- 15 Years OEM and ODM experience in plastic injection molding service for Electrical parts, Medical treatments, Bathroom plastic accessories, Telecommunication devices, Toys and Crafts: One stop tooling room and injection center.

2- Advanced equipment and peofessional technology: CNC, CMM and injection machines from 80MT-1200MT.

3- Advanced R&D service and Best Engineer: DFM and Mold Flow Analysis.

4- Excellent and Nice IML (In Mold Labeling) technology, we can put labels on 4 sides in the mold together when injection.

5- Quality and Price: Quality-oriented and cost drivers analysis to share cost reduction with customers.

6- Series service of design, prototyping, paiting, printing and assembly( 3 assembly lines for finished products).

Send Inquiry to This Supplier

You May Also Like

-

Factory Sell Directly Industry Heat Printing Endless Nomex Felt Belt Felt CylinderUS$ 50 - 220MOQ: 10 Pieces

-

Quench , Temper , Annealing Quick Turn Precision Machining For InfrastructureNegotiableMOQ: 1 Square Meter

-

Plain Steel Tools , HVAC , Fork Lifts CNC Machining Services Shafts With Worm GreaNegotiableMOQ: 1 Square Meter

-

GCR 15 Durable Belt Tensioner BearingNegotiableMOQ: 1 Square Meter

-

Sintered Powder Metallurgy Shock Absorber Piston D35XD10X13.5US$ 0.25 - 0.40MOQ: 1 Square Meter

-

Eco-friendly Polyester Activated Carbon Cloth for Air / Water / Oil Filtration /charcoal Filter Cloth on SaleUS$ 3.2 - 4.5MOQ: 100 Kilograms

-

Energy Conservation and Environmental Protection Filter Press ClothUS$ 100 - 1,000MOQ: 1 Set

-

Plus Dust Filter With Cloth Bag Used in MetallurgicalUS$ 230,000 - 890,000MOQ: 1 Set

-

Activated Carbon Polyester Air Filter Rolls Pads Felt Quality ChoiceUS$ 60 - 150MOQ: 50 Rolls

-

Filter Cloth;Filter Cloth Steel WireNegotiableMOQ: 1 Piece