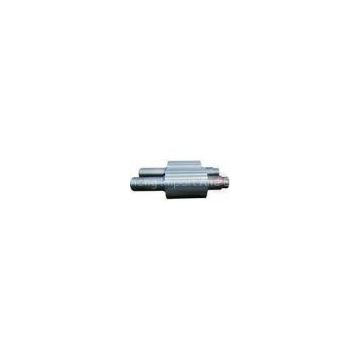

High Hardness Finish Machined Roller Forging Steel 60CrMnMo Cr3 , EN ASTM GB

Certification:Certification: MTC, Chemical composition, mechanical properties, UT, MT, dimension report, heat treatment record etc.

High Hardness Finish Machined Roller Forging Steel 60CrMnMo Cr3 , EN ASTM GB

High hardness alloy steel or carbon steel metallurgical machinery forged steel lower roll for rolling machine

China manufacture high wear resistance 4140 metallurgical machinery forged alloy steel rollers

Quick Detail:

1. Lower roll for rolling machine, forged steel roller, alloy steel roller, stepped steel roller, alloy steel forging roller,

cold roller, hot roller, carrier roller, rolling rod

2. Alloy steel, carbon steel or as per customer’s requirements

3. Mainly applied in metallurgical equipment

Description:

1. The lower roll for rolling machine is mainly used in metallurgical machinery, such us cold roller, hot roller, rolling

machine, etc.

2. It is high strength, high heat resistant and high corrosion resistant.

3. It could be rough machined or finish machined as per clients’ request.

4. Full testing report will be sent before shipping, including chemical analysis, dimensions, mechanical properties,

UT.

Specifications:

|

Item |

Lower roll for rolling machine |

|

Material |

4140, 20CrMnMo, Cr5, Cr3, 60CrMnMo, etc |

|

Material standard |

EN, ASTM, GB, ISO |

|

Dimension |

Max. OD: 1300mm, Max. Length: 15000mm |

|

Weight |

Max.: 150T |

|

Smelting process |

EF+ LF + VD(double) |

|

Forging & machining process |

Ingot→Heat→Forging→Heat treatment (Normalizing+tempering)→Inspection→ Rough machining→UT→2nd Heat treatment →Finished machining →Inspection |

|

UT Standard |

EN, ASTM, GB |

Applications:

Lower roll for rolling machine is widely used for metallurgical equipment, rolling machine.

Competitive Advantage:

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment,

machining and strictly final inspection prior to delivery.

Excellent product quality and service, competitive price, “in-time” delivery.

Why us?

1) We have been in the field of forging for more than 10 years, with plenty of experience in forging and machining

different forged products.

2) With variety of forging equipments and machining devices, we are capable of producing all forgings you need.

3) With reasonable management, we could finish forging and machining shorter time.

Send Inquiry to This Supplier

You May Also Like

-

Excavator Hydraulic Pump With SAE J744 Standard Compliant for Global CompatibilityNegotiableMOQ: 500 Pieces

-

Supply Excavator Fuel Oil Stop Solenoid Valve B4002-1115030NegotiableMOQ: 1 Cubic Meter

-

352-4500 3524500 OEM New Hydraulic Axial Piston Pump R986111086 972M XCMG XE CAT 966L 966K 966 966MNegotiableMOQ: 1 Piece

-

Chromium Carbide Overlay Wear Plate Excavator Crusher Bucket LinerUS$ 399.69 - 399.69MOQ: 1 Square Meter

-

For Volvo Penta Fuel Filter 20998367 (7420514654 – 20998367)NegotiableMOQ: 1 Piece

-

High-quality Garrett 762931-0001 Turbo/turbocharger Available for Immediate SaleUS$ 120 - 150MOQ: 1 Unit

-

Precision-Machined Excavator Hydraulic Pump With Mill Test Report IncludedNegotiableMOQ: 500 Pieces

-

Excavator Hydraulic Pump for Long-Reach Demolition and Heavy Lifting OperationsNegotiableMOQ: 500 Pieces

-

Excavator Hydraulic Pump With Cast Iron Housing and 350 Bar Pressure RatingNegotiableMOQ: 500 Pieces

-

Excavator Hydraulic Pump High Pressure Radial Piston Oil Pump Mini Excavator PartsNegotiableMOQ: 500 Pieces