Screws vs

ls? And sometimes there's no consensus.

Is there a case where nails are better than screws, from a structural standpoint? For instance: Say you used screws instead of nails on a backyard deck, when the design specifically called for nails. Would the result be inferior? Could it fail inspection? Would nails absolutely be preferable in this instance? Are there any rules of thumb about when to use screws vs. nails?

Screws are a "superior" fastener over a nail (they have far superior tensile strength)—especially if you're talking about screwing down decking. However there are many scenarios where a nail is the proper fastener for the application (attaching joists is one example—screws are brittle and will fail when subjected to the forces of a shear loaded application).

Using your deck example—you should use nails to attach the joists to the deck framing but use screws to fasten down the decking itself.

Nails are used in almost all framing and structural applications. Most code books are designed with nails in mind and will have specific minimum nailing requirements and patterns for different applications.

Structural screws are coming more and more on the market every day, but because most code books don't include them you will need an engineer's approval of their use to pass inspection in many cases. If you want to use structural screws without paying the big $$ for an engineer you should talk with your municipal build dept. first to see if they will allow it.

Your normal wood screws are not structural. Standard screws are brittle. If you take a normal screw and drive it part way in and whack it with a hammer, it will snap. If you do this with a nail, the nail will bend. Which would you rather have holding your deck up? Something that bends but stays intact or something that can snap?

In the end: nails, hex bolts, and lag bolts are still better in most applications. Structural screws are just easier than bolting and cooler than nailing.

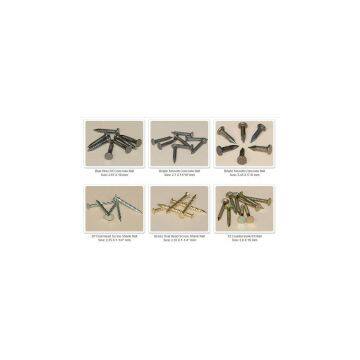

8. Hardware Nails, Roofing nails, Box Nail, hot-dipped galvanized smooth nails

Hardware nails from KRS can help your business in virtually any of your fastening jobs. Find the variety of common nail you want in an array of sizes, gauges and finishes to suit your project's needs. Roofing nails are available for roofing and sheathing in a variety of quantities and lengths from 1 to 2 inches. Or select a brad nail to hang paneling, or install baseboards, door trim and window trim. Grainger nails your needs for hardware nails.

Box Nail, Steel, Hot Galvanized Finish, Head Type Flat, Shank Type Smooth, 6d Size, 17/64 In Head Dia, 12 1/2 Gauge, 0.099 In Dia, 2 In Length, Package Weight 1 Lb, Package 236

2-Gauge 6-in Hot-Dipped Galvanized Smooth Nails

Most popular nail and versatile style

For construction, carpentry and framing

Larger shank for more strength

Flat head and diamond point

Galvanized for limited resistance to rust

Send Inquiry to This Supplier

You May Also Like

-

3inch Yellow Zinc Coated Threaded Nails for Structural FasteningNegotiableMOQ: 5 Tons

-

Fit R175-C Roofing Coil Nailer Roofing NailsUS$ 15 - 32MOQ: 100 Cartons

-

1 1/2" Yellow Zinc Coated Threaded Nails for Roofing ApplicationsNegotiableMOQ: 5 Tons

-

Yellow Zinc Coated Threaded Nails With Plastic Caps for Roofing FixingNegotiableMOQ: 5 Tons

-

Black Threaded Nails 1 1/2" to 3inch for Heavy-Duty FramingNegotiableMOQ: 5 Tons

-

2inch Black Threaded Nails With Warranty for Industrial UseNegotiableMOQ: 5 Tons

-

Yellow Zinc Coated Threaded Nails 1-3inch for Roofing, Structural FasteningNegotiableMOQ: 5 Tons

-

Black Threaded Nails 1inch to 2inch for Wood-to-Wood ConnectionsNegotiableMOQ: 5 Tons

-

1inch to 3inch Yellow Zinc Coated Threaded Nails for ConstructionNegotiableMOQ: 5 Tons

-

Black Threaded Nails 1inch to 3inch for Concrete FormworkNegotiableMOQ: 5 Tons