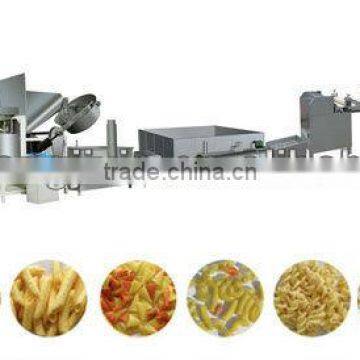

Series of Inflating Food Machine With Excellent Quality

Food screw extruder mainly contains :feeding systems, extruding systems, cutting systems,heating systems,gearing systems, lubricating system, control system, it can produce snack food, pet food etc by changing the different screw, we have many model, it can meet customer’s different requirments.

Introduction:

The line is a kind of extruded snacks, using corn grits as raw materials meanwhile mixing with water and oil,very crunchy and great in taste. Kurkure/Cheetos snack food is made by extrusion process. The snack food are moisturized in a vertical mixer with water, oil then feed to the Rotary Head Extruder. In the extruder, due to excess heat and pressure from the screws the meal gets heated and the moisture content gets reduced. The meal passes through the die and gets cut by the cutting knifes into required lengths. The kurkures/cheetos snacks food is fried in cooking oil and then cooled before flavoring. Seasonings are sprayed on the kurkures snack food to improve their taste.

Voltage:

Three phases: 380V/50Hz, Single phase: 220V/50Hz, we can make it according to customers' Local voltage according to different countries

The production process flow:

Mixer---Screw conveyor---extruder--Elevator---Cooling machine---Shaking machine---fryer---Automatic flavoring machine --cooling machine

The detailed information for Kurkures/cheetos,Nik naks snack food line

NO | Machine

| Motor Power

| Capacity

| dimension

| Quantity

| Function |

1 | Mixer | 4KW | 300kg/h | 0.8*0.7*1.5m | 1set | To mix the raw materials with the water |

2 | screw conveyor | 1.1KW |

| 3.0*0.8*2m | 1set | To send the materials to the extruder |

3 | Snack extrude machine | 30KW

| 100kg/h | 2.6*1.5*2.8 m | 1set | To extrude and inflate the food. |

4 | Elevator | 0.75KW | 100-150kg/h | 2.4*0.8*2m | 1 set | this conveyor just take the raw kurkure snacks to cooling machine |

5 | Cooling machine | 4KW | 200kg/h | 0.2*0.9*1.5m | 1set

| in order to cooling the hot kurkure snacks out of the extruder |

6 | Shaking machine | 4KW | 100-200kg/h | 1.3*0.6*0.65m | 1set | cooling and separate the stick kurkure snacks .and send them to frying machine |

7 | Flavoring machine | 12kw | 100-200kg/h | 2.2*0.65*1.85m | 1set | coating the flavoring powder on the kurkure snacks food surface after frying . |

8 | cooling machine | 1.2kw | According to the extruder | 6m length | 1set | To cool the Kurkure snack snack reduce the temperature before packing

|

About installation and after-sale service system:

- We can provide factory layout according to customer’s factory size in advance.

- When we received your deposit of this order, we will ask our engineers to prepare to apply the visa, when the machine arrived your country, and we will send two engineers to go and help you to install the processing line, teach your worker(3-4 workers) how to operate the line, until yourworker know the line well

- Our engineers has responsibility to teach your worker how to clean the extruder, how to change the screw, how to change barrel etc. and we have responsibility to provide technology support with you forever.

- Our engineers can provide basic formula for producing the Kurkures/Nik naks and help customer to produce good quality food according customer’s detailed formula.

- We provide the spare parts will at preferential price for an extended long time.

- other item:

a). Free consultation service before, during, and after sales;

b). Free project planning and design services;

c). Free debugging of equipment until everything is functional;

d). Free management of equipments' long distance shipping;

e). Free training of equipment maintenance and operating personally;

f ). Free new production techniques and formulas;

g). Provide 1 year complete warrantee and life-time maintance service;

Send Inquiry to This Supplier

You May Also Like

-

Commercial Coffee Roasting Machine With Digital Controls for Specialty Cafes and RoasteriesNegotiableMOQ: 1 Set

-

Commercial Fried Ice Cream Roll Machine With Single Square Pan and Double Pan Nine BarrelsNegotiableMOQ: 1 Set

-

Waffle Cone Maker Ice Cream Cone Machine Ice Cream Cone Production LineNegotiableMOQ: 1 Set

-

Small Scale Automatic Yogurt Making Machine Yogurt Production LineNegotiableMOQ: 1 Set

-

Hot Hydraulic Car Brake Fluid DOT3NegotiableMOQ: 1

-

LS Electric Motor ScooterNegotiableMOQ: 1

-

Precision CNC Turned PartsNegotiableMOQ: 1 Set

-

3 Way Speaker FilterNegotiableMOQ: 1

-

Food Kiosk Kebab Trailer, Hot Dog Cart Mobile Food, Food Cart Manufacturer PhilippinesUS$ 1,200 - 2,500MOQ: 1 Set

-

21 Power-driven Chip Twister MachineNegotiableMOQ: 1 Set