Specifications

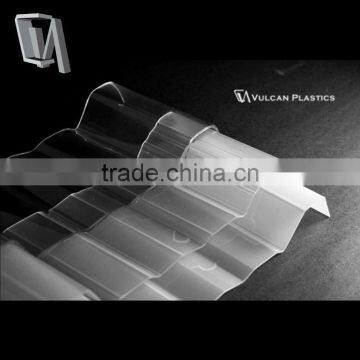

Polycarbonate Corrugated sheet (Valuview TRIMDEK)100% Virgin Mitsubishi resin

SD UV400 Coating

10 years warranty

VULCAN Polycarbonate VALUVIEW TRIMDEK

TRIMDEK (190/27)

Apart from using the best raw materials, VULCAN Polycarbonate TRIMDEKprofile sheet differs from other brand products by having added grooves at the 131mm area to allow faster drainage. VULCAN TRIMDEK profile sheets have a long lifespan and is extensively tried and true in the Americas; choose between five different material grades to suit your needs*.

Width | Wave Span | Wave Height | Thickness | Production Length | |||

Min. | Max. | Min. | Max. | 20' | 40' | ||

5 Corrugations | 190mm | 27mm | 0.6mm | 2.0mm | Max. | Max. | |

820mm | 5800mm | 11600mm | |||||

Specifications

- Profile: Polycarbonate TRIMDEK Corrugated (5 Corrugations)

- Raw Material: 100% Virgin Resin from Mitsubishi Japan, Bayer Germany, Sabic (GE).

- UV Coating: Optical Grade SD Polyca UV400 Coating (Sumitomo Dow Chemicals Japan)

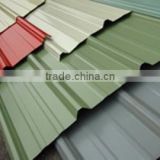

- Standard Colors: Clear, Bronze, Blue, Green, Opal.

- Thickness: 0.6mm~2.0mm

- Width: 820mm

- Length: 2440mm, 3660mm, 4880mm, 5800mm, 5900mm, 9000mm, 10000mm, 11000mm, 11600mm (other sizes can be cut to length upon request)

- Warranty: 10 years. (5 for yellowing, 10 for usage)

Product Strengths

Base Material

- 100% Virgin UV included raw material ensures that your sheets can withstand harmful UV rays for at least one year.

UV400 Coating

- Optical Grade SD Polyca UV400 coating as used on lenses, glasses, and sunglasses. 99.5% of harmful UV wavelengths between 290nm~400nm are blocked.

Production Method

- Co-Extrusion ensures evenly spread, evenly thick base material and UV coating. (A chain is only as strong as it’s weakest link.)

High impact resistance

- 250 times the impact strength over glass and 10 times over FRP and Acrylic.

Fire Retardant

- Polycarbonate sheets produced with 100% Virgin material have a melting point of at least 190 degrees Celsius and produce only odorless smoke when burned.

Design Flexibility

- VULCAN Polycarbonate sheets can be tailored with different coatings to provide different light transmission rates and properties. Customers can choose between LiteGuide, Pearly RED, Pearly GREEN, Ti-Lite, and Valuview.

Quality Standards

VULCAN Polycarbonate sheets are produced with the highest of standards available in the industry. We are the first Polycarbonate manufacture in Asia to incorporate clean rooms for all of our extrusion lines. Our latest Breyer Solid Flat sheet machine is installed in a Class 5000 clean room (the maximum number of particles per cubic foot of air of diameter greater or equal to 0.5 µm is 5000).

Machinery

We have a total of 5 co-extrusion lines, 2 for corrugated sheets and 3 for solid sheets. Our machines are imported from Toshiba-Hitachi Japan, Omipa Italy and Breyer Germany. Our co-extrusion machine uses feedblocks from the industry leading EDI (Extrusion Dies Industries) company and controlled by the also industry leading Dynisco company computers.

Applicable Areas

Agricultural Greenhouse

Garden Greenhouse

Flower Greenhouse

Multi-span Greenhouse

Singe-span Greenhouse

Greenhouse roofing

Greenhouse Walls

Aquaculture Greenhouse

Polycarbonate sound barriers

Polycarbonate Highway barriers

Polycarbonate Skylight

Polycarbonate Warehouse

Polycarbonate Roofing

Warehouse Roofing

Warehouse Skylight

Industrial Skylight

Interior decoration

Car Park

Glazing

Patios

VULCAN Polycarbonate Corrugated Sheet Valuview TRIMDEK (5 corrugations) sheet is our best selling profile in Asian countries including Taiwan and southeast Asia.

VULCAN Polycarbonate Corrugated Clear Sheet Valuview TRIMDEK uses imported 100% Virgin Resin from Mitsubishi Japan, Bayer Germany, Sabic (formerly GE) and SD Polyca Optical Grade UV400 Coating from Sumitomo Dow Chemicals Japan to block harmful UV rays.

VULCAN Polycarbonate Corrugated Clear Sheet Valuview TRIMDEK are produced using advanced Co-Extrusion process to ensure an evenly UV coated surface.

Our Co-Extrusion Machines uses EDI (Extrusion Dies Inc.) feedblocks to ensure even material flow.

Even material flow= Even UV400 surface Coating = Withstand sunlight longer = Long lifespan of sheet

The whole Co-extrusion process is fully computer controlled by Dynisco systems.

Impurity leads to less quality, which is why VULCAN Polycarbonate sheets are produced in clean rooms; the cleaner the environment, the cleaner the sheets, and hence a longer lifespan.

Optional Plus+ surface treatment provides additional light softening properties. (MOQ required)

Standard colors are: Clear, Bronze, Blue, Green and Opal; other colors can be made to order.

Other proprietary material from VULCAN Plastics

Send Inquiry to This Supplier

You May Also Like

-

Quality PVC Interior Ceiling Panel Modern Design Fireproof Perforated Ceilings Easy Installation With Ceiling GridNegotiableMOQ: 1000 Square Meters

-

Outdoor Signs for Sales, AdvertisementNegotiableMOQ: 5000 Pieces

-

Factory Wholesale Supply Rain Water Drainage Plastic Pvc Rain Gutter Cover Roof Anti Leaf Rain Gutter GuardUS$ 1.53 - 1.74MOQ: 3000 Pieces

-

10mm Thich Hdpe Pe300 Extruding Plastic SheetUS$ 2 - 5MOQ: 1 Blade

-

Plastic Tube Steel Security Half Round Fence Post CapsUS$ 0.09 - 0.31MOQ: 1 Piece

-

High Quality Plastic Polypropylene Retort Separator SheetsNegotiableMOQ: 1

-

Super Clear Transparent Door Colourful PVC Strip Curtain Rolls PVC Door CurtainNegotiableMOQ: 1

-

SANHONG High Quality EVA Sheet Foam Supplier Roll EVA Mats ManufacturerUS$ 130 - 142MOQ: 28 Cubic Meters

-

Carrier Bag Making MachineUS$ 5,000 - 10,000MOQ: 1 Set

-

Eco-friendly Wine Holder Bag Felt Printed Christmas Logo Leather Cutting LogoUS$ 1.5 - 2MOQ: 200 Pieces