Toilet paper making machine

A:The parameter of 1760mm Toilet Paper Making Machine

Technical data | |

Output paper | Toilet paper |

Output weight | 14—40g/m2 |

Net width | 1760mm |

Wire width | 2250mm |

Capacity | 5T/D |

Working speed | 100-150m/mm |

Rail gauge | 2600mm |

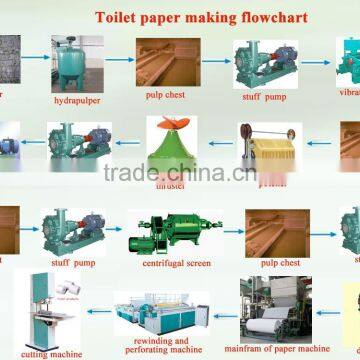

B:tissue paper making machine all equipments list

Number | Equipment | Quantity (SET) |

1 | 1760mm tissue paper machine mainframe | 1 set |

2 | Exhaust hood of the dryer can(double layers) | 1 set |

3 | 850 screw type ventilator | 1 set |

4 | Cylinder mould pressure forming machine | 1 set |

5 | 15 type roots pump | 1 set |

6 | suction box | 2 sets |

7 | 5m3 high consistency hydraulic pulper | 1 set |

8 | 2m2 high frequency vibrating screen | 1 set |

9 | 35m3 potcher | 2 sets |

10 | 700 Thruster | 4sets |

11 | 380mm double type pulp grinder | 1 set |

12 | 0.9 m2 centrifugal screen | 1 set |

13 | 606 sand cleaner (6 pcs) | 1group |

14 | Two-phase flows pulp pump-100 | 6 sets |

15 | Two-phase flows pulp pump-150 | 4 sets |

16 | 1760mmrewinding&perforating machine | 1 set |

17 | 450mm toilet roll cutting machine | 1 set |

18 | Air pump | 1 set |

19 | Frequency conversion& synchronous control cubicle | 1 set |

20 | The whole set of work bench | 1 set |

21 | 2T boiler | 1set |

Main structure:

1. cylinder part: 1500mm×2250mm stainless steel wire mould(1pc), Cylinder mould pressure forming machine (1 set),450mm×2250mm couch roll(1 pc),rubber HSD38°±2

2. Dryer part: 2500mm×2250mm Dryer ( 1 pc ), 500mm×2250mm carrier roller( 1 pc ), air-powered pressure device,rubber HSD 90°±2, there is double-layer exhaust bood on the dryer.

3.Winding part:1000mm×2250mm sweat cylinder (1pc),280mm×2250mm fly rubber roll( 1pc ).rubber HSD75°±2. winding on the sweat cylinder.Equipped with the 250 speed reducer(1 set)

4. Rewinding and cutting part: matching 1760mm rewinding and perforating machine,toilet roll cutting machine..

5. Drive and control part: adopting AC frequency conversion speed, drive step by step.

1. Pre-sales service

- Offering comprehensive technical and business consultation services;

- Proposing the most suitable scheme and equipment for our clients;

- Designing and fabricating targeted products according to the special requirements of clients;

2. After-sales Service

- Highly inspecting equipments in every working procedure, quality comes first;

- Fast & Safe Delivery; multi-cylinder

- Assisting our clients for foundation construction of equipments;

- Dispatching engineers to install and debug equipments;

- Training the first-line operators on site;

- Regularly visit clients to solve production problems;

- Providing life-long maintenance service;

- Providing technical exchanging;

Send Inquiry to This Supplier

You May Also Like

-

Automatic Rotary Egg Tray Equipment / Egg Tray Production LineNegotiableMOQ: 1

-

Automatic Paper Recycling Machine for Produce Craft Paper From Www.frdpapermachine.comNegotiableMOQ: 1 Set

-

Toilet Paper Cutter/Kitchen Towel Cutting Machine Price With High PerformanceUS$ 1,500 - 2,000MOQ: 1 Set

-

2020 New Fabric Roll Strip Slitting Cutting MachineUS$ 3,200 - 4,200MOQ: 1 Set

-

Paper Tray Forming Machine That Make TraysUS$ 10,000 - 20,000MOQ: 1 Set

-

1092mm Paper Wideth 4-5 T/d Capacity a4 Printing Paper Making MachineUS$ 20,000 - 150,000MOQ: 1 Set

-

Waste Paper Recycled Egg Tray Making MachineUS$ 7,000 - 7,000MOQ: 1 Set

-

Mechanical Screening Equipment 0.6M2US$ 2,000 - 20,000MOQ: 1 Unit

-

High Speed Automatic Paper Feeding A4 Office Paper Cutting MachineUS$ 10,000 - 135,000MOQ: 1 Set

-

3600mm Multi Wire Fluting Paper Machine Production Line Made Paper in 110-250gsmUS$ 160,000 - 250,000MOQ: 1 Set