Advance Hydraulic Press Design System Wood/biomass Briquette Extruder Machine

Advance hydraulic press design system wood/biomass briquette extruder machine

l Introduction of Wood briquettes extruder machine/biomass briquette machine

This Wood briquettes extruder also called biomass briquette machine and sawdust briquette making machine, is used to make sawdust into half-charcoal-stick. It is equipped with the auto-controlling heating system. The byproduct of this machine can be used to heat boiler, fireplace, etc for warm in house. Using the inherent characteristics of wood raw materials, through the screw extrusion, high temperature, high pressure, the wood raw material to make micro-fiber lignin plastics combine to form a fuel rod. It is the main equipment to make stick solid fuel with such wood material as bits of wood, rice shell or peanuts shell, etc. The raw material(12% Water proportion) dried by the dryer(12% humidity)will be formed into fuel under high pressure and at high temperature. During this process, no need to use binder and noxious chemical.

l Working Principle of Wood briquettes extruder machine/biomass briquette machine

Briquetting is a process that biomass is compressed under high pressure and high temperature.The lignin content that occurs naturally in biomass is liberated under high pressure and temperature. Lignin serves as the glue in the briquetting process, thus binding, compressing the biomass to form into high density briquettes.During this process, no binder needs to be used. So the output briquette is a type of clean and green fuel that is ideal for use in furnaces, boilers and open fires. The density of the briquettes is 900-1400kg/m2.

advantages of wood briquette machine :

1)Widely applied raw matrerial: nearly all kinds of biomass wastes can be recycled into

biomass fuel.

2) High quality: Our factory has been specialized in straw briquette press machine for

over 30 years, so we can guarantee our quality.

3) Reliable service: Our engineer can draw the layout for you, and can install the whole line,

train your workers at the same time.

4) Other technical support: we not only can provide you machines, but also technical support.

Detailed parameters of all the models for your checking:

Model | MF-50 | MF-80 |

Output (kg/h) |

180-210 |

340-360kg |

Motor Power (kw) |

15 kw |

22kw |

Electric heater (kw) |

2kw×3pcs |

2kw×3pcs |

Weight(kg) |

700 kg |

1100kg |

Overall dimension(mm) | 1780*750*1290 | 1960*880*1620 |

Size of finished products |

Diameter: |

Diameter: |

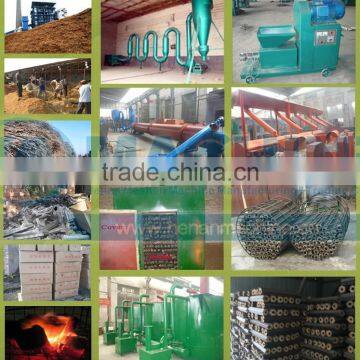

The auxiliary machine:

Transfer machine

l Spare parts of Briquette Making Machine:

| |

| |

| |

| |

| |

Crushing machine

rotary screen

dry machine

material distributer:

spare parts

finally product

Payment,Packing and Delivery

Payment :30% TT in advance, 70%6TT balance pay off before delivery.

Packing: The machine and wear parts will protected by plywooden box or as customers’ will.

Delivery time: For one set, the delivery time is 7-10 days, for 1-5 sets 20-25 days, above 5 sets usually negotiate.

Shipping company: MSK/MSC/APL/EMC/WANHAL/KLINE and We will remind you before boat arrive and offer you all the customs clearance documents on time.

Contact Information

Thanks for your interest in our machines and please contact us freely if you have any questions ot requirements by the following contact information. Your visit of our factory to test the machines you like will be warmly welcomed. Hope to have have the honor to cooperate with you in the bright future.

Send Inquiry to This Supplier

You May Also Like

-

16kVA Standby Power Diesel Generator PoweredNegotiableMOQ: 1 Set

-

Granulator Machine Biochar Production Line Pellet MachineUS$ 690 - 3880MOQ: 1 Set

-

Humic Acid Fertilizer Pellet Machine(CE)US$ 880 - 99,000MOQ: 1 Set

-

Pellet Briquetting Machine / Rice Husk Pellet Mill PriceUS$ 25,000 - 25,000MOQ: 1 Set

-

Wood Pellet Mill Machine for Wood Dust Pellet PressUS$ 1,000 - 10,000MOQ: 1 Set

-

Energy Saving Straw Coal Briquette MachineUS$ 2,000 - 3,000MOQ: 1 Set

-

Diesel Flat Die Small Pellet MillUS$ 500 - 1,000MOQ: 1 Set

-

Industrial Complete Flat Die Wood Pellet Production LineUS$ 20,000 - 25,000MOQ: 1 Set

-

Factory Directly Wood Pellet Press, Wood Pellet Press Machine, Gemco Supply Wood Pellet MillUS$ 3,000 - 4,000MOQ: 1 Set

-

Hot Sale and Best Quality Wood Briquette Machine Screw PressNegotiableMOQ: 1 Set