Zinc oxide production equipment manufacturer by Derui Machinery

Zinc oxide production equipment:

Zinc oxide is a commercially valuable product. Zinc oxide is a white powder that has a variety of uses including as an accelerator activator, as a pigment, as a dietary supplement, as a rubber tire component, and in the semiconductor field.

Structure of zinc oxide production equipment:

Zinc oxide production equipment is composed of cylinder, supporting device, supporting device with catch wheel, transmission device, active kiln head, sealing device, burning device and feeding device and kiln head combustion equipment, etc.

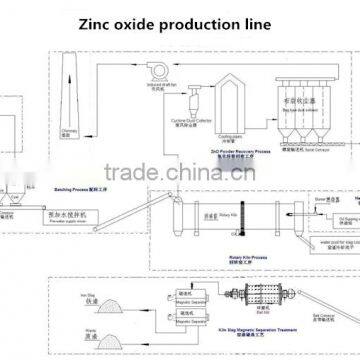

Working process of Zinc oxide production equipment:

The EAF dust generated by steel mills can be recycled in an economically viable way using the Waelz Kiln technology. The recycling process is part of the larger steel industry loop that allows the reuse of two important natural resources - zinc and iron.

1.Raw material preparation, batching, blending and feeding process

The raw material , such as EAF dust and coal is transported into stock yard.

There are two receiving hoppers, the materials are feeding into receiving hopper by loader. At the bottom of hopper, there are constant weight feeder to supply each materials quantitatively, after mixing by mixer and then are send into kiln end by belt conveyor to blend the materials together.

2.Oxidation-reduction process in kiln

The blended materials are feeding into rotary kiln by belt conveyor, because there is coal added in the blended materials, when the materials are moving to the kiln end, the coal is burning and creating heat, so the material temperature is getting higher and higher.

At the temperature of 1150+/50 degree celsius, with help of coal as reducing agent, the valuable metal such as Zn will be reduced and volatilized as metal vapor int the dust collecting system.

3.ZnO powder recovery system

The fume from kiln end will firstly enter into settling chamber and then enter into surface cooler for cooling to 300 degree celsius under and then enter into bag type dust collector, then exhaust into air.

The dust collected in surface cooler and bag type dust collector are final ZnO powder products.

The quality of coarse materials from settling chamber and the former part of surface cooler are not meeting requirement, these materials will be sent back to the feeding hopper at the kiln end for re-calcination.

4.Finished products storage and package

At the bottom of the bag type dust collector, there are screw conveyor to collect and send the final products via bucket elevator into intermediate silo.

At the bottom of silo, there is fixed type packing machine for packaging.

5.Kiln slag treatment

At the kiln head, there is water cooling pool. The kiln slag is directly discharged into water pool for cooling, and then is transported by loader to the stock yard for sale or for further process. The cooling water is entering to water recycling system.

The kiln slag is transported into pit hopper by loader .The crushed slag is entering into ball mill for grinding and then entering into two stage magnetic separators for separation , of which, one is for roughing, the other is for cleaning, then get final Fe concentrate.

The waste water will be recycled after sediment, there is no waste water discharging in this process and no harm to environment protection.

The waste after magnetic separation can be used for construction materials. It is no harm to environment.

Application of Zinc oxide production equipment:

Zinc oxide production equipment is mainly used for heating and calcining various mineral materials in metallurgy, construction, and ores etc, such as ceramsite sand, bauxite, limestone, cement, metal magnesium, alumina, hydroxide alumina, fly ash , high aluminum refractory materials, etc.

Derui Introduction:

Gongyi Derui Machinery Co., Ltd is located in Zhengzhou, Henan, China(mainland).Our main product include: Zinc oxide production equipment, stone crusher, ball mill, mineral ore dressing equipment, dryer plant, grinding equipment, etc.

If you are interested in our Zinc oxide production equipment, please kindly inform us the following info:

1. what is the raw material that you are going to process?

2. what is the capacity per day or per hour?

3. what is the feeding size of raw material?

4. what is your heat source?

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Send Inquiry to This Supplier

You May Also Like

-

Wheat Flour Mixing Machine Coffee Milk Protein Powder Mixing Machine Animal Feed Mixer Blend Machine With CEUS$ 880 - 2290MOQ: 1 Set

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Factory Supply Cco Plate Mixed Concrete Batching Plant Wear Resistant LinersUS$ 500 - 500MOQ: 1 Set

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set