Limestone Calcination Equipment, Limestone Roary Kiln, Lime Production Machine

Limestone calcination equipment, limestone roary kiln, lime production machine

Limestone rotary kiln is the key equipment for the lime production process in the building materials, its main role is calcining raw materials with high calcium carbonate, such as limestone, dolomite, chalk, shells and other materials to produce lime.

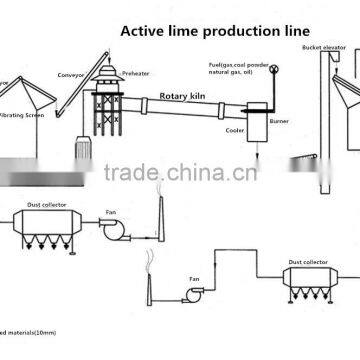

Limestone rotary kiln's structure is advanced, low pressure vertical preheater can effectively improve the preheating effect ,after preheated, limestone enter into the kiln and is calcined in the optimum temperature of 900 ~ 1100 degree, the decomposition rate can reach 20-25%,the efficiency is higher ;the sealing system on the both sides can make the rotary kiln air leakage coefficient less 10%,thus can reduce effectively heat loss ;the cooler on the rotary kiln's discharging mouth can control the lime temperature in 800 degree ,in order to transport and storage.

Lime stone in the preheater can be heated to 900 degree by high temperature kilns flue gas,and about 30% is decomposed,the hydraulic rod push them into the cooler.In the cooler,active lime is cooled to below 100 degree by the cool air,In the actual situation,in order to reach this temperature,in the premise of not affecting the kiln head roasting process,control the air amount of the cooler and wind pressure to ensure the effect.

Limestone rotary kiln working site:

Lime production process:

Limestone in the lime industry is a general term for rocks that contain eighty percent or more of calcium or magnesium carbonates including marble, chalk, oolite, and marl. Further classification is by composition as high calcium, argillaceous (clayey), silicious, conglomerate, magnesian and other limestones, and dolomite.

Uncommon sources of lime are coral, sea shells, calcite, and ankerite. Limestone is extracted from quarries or mines. Part of the extracted stone, selected according to its chemical composition and granulometry, is calcinated at about 1,000 °C (1,830 °F) in different types of lime kilns to produce quicklime according to the reaction: CaCO3 + heat → CaO + CO2.

Before use, quicklime is hydrated, that is combined with water, called slaking so hydrated lime is also known as slaked lime, and is produced according to the reaction: CaO + H2O → Ca(OH).Dry slaking is when quicklime is slaked with just enough water to hydrate the quicklime but remain as a powder and is referred to as hydrated lime. In wet slaking enough water, but not too much, is added to hydrate the quicklime and form a putty referred to as lime putty.

Limestone rotary kiln shipping:

About Derui Machinery:

Derui machinery Co., Ltd is located in Gongyi city of henan province, our main products include following:

Stone crusher series: jaw crusher, impact crusher, cone crusher, etc.

Sand-making equipment series: VSI-IV sand-maker, PCL sand-maker, sand-washer, etc.

Beneficiation equipment series: Ball mill, magnetic separator, flotation machine, high frequency screen, spiral classifier, rotary dryer, shaking table,jigger machine, mixer, pendulum feeder,concentrator,spiral chute, etc.

Feeding and screening equipment series: vibrating screen, vibrating feeder, etc.

Rotary kiln:Lime rotary kiln, cement rotary kiln, etc.

Accessory equipment: belt conveyor, bucket elevator, screw conveyor, etc.

How to visit us ?

If you want to visit our factory, please note our city name, Zhengzhou City, Henan Province, China(mainland)

Our air port name is : Zhengzhou Xinzheng International air port.

Train station name is: Zhengzhou (Zhengzhou north) train station

Send Inquiry to This Supplier

You May Also Like

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Multi-function Powder Mixing Equipment Stainless Steel U-typed Powder Blender Flour Double Screw Mixer With CEUS$ 880 - 2290MOQ: 1 Set

-

Separator Rotar Cement Mill Liner PlateUS$ 256 - 256MOQ: 1 Piece

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set