Good Performance Continuously Auntomatic Rubber Pyrolysis Plant For Fuel Oil

40-60 Ton Fully Continuous Pyrolysis Plant

1. Plant Features:

1) widely usage

Can be used for tyre 5-10cm,plastic,rubber ,oil sludge, cooking waste ,live waste, oil sand ,oily soild

2) static pyrolysis ,getting higher quality oil, less dust in oil

3) large capacity

24hours produce 20-30 Ton material

4) continuous pyrolysis, no need cooling reactor, saving fuel, saving working time

5) The plant can working 25dyas*24hours without stop, fully continuous

6) Continuous feeding without stop

7) Continuous slag out without stop

8) Non-liquid gas can be reused to support heating for heating reactor , saving fuel energy

9) good pressure tightness, safe

2. Technical parameter

Reactor size | (L*W*H)12*2*2.5m |

volumn | 60M3 |

material | Q345R/Stainless steel |

Work pressure | Normal pressure/slightly negative pressure |

Process capacity /24hours | 60 Ton tyre |

40 Ton plastic | |

Oil sludge 40-60Ton | |

Oil sand 40-60TON | |

output | Base oil |

Working principle | Oxygen free pyrolysis |

workers | 1 |

power | 20/40kw |

voltage | 220v/380v |

Power consumption/24hours | 230 kw |

Water consumption | 4-6Ton |

Feeding time | Continuous feeding |

Carbon discharge time | Continuous slage out |

working life time | 4-5yeat |

Slag temperature | 150℃ |

Fuel | Gas, oil |

Pyrolysis way | Static pyrolysis, non-rotate |

Slag way | Continuous slag out |

Dust smoke temperature | 350℃ |

Pyrolysis temperature | 280-350℃ |

Max-temperature | 600℃ |

oil come temperature | 350℃ |

Raw material delivery speed | 0.4-2m/min |

3.Work-flow:

4.Pyrolysis Plant Type Difference

Type | Feeding way | Heating way | Heating fuel | Reactor type | Pyrolsysis way | environmental effect | Featurs |

Batch | By human | Direct /indirect heating | Coal, wood, oil, gas | Round type/cylinder | Rotation pyrolsysis | environmental | After one batch need to cool down |

Semi-continuous | Auto-feeder | Direct /indirect heating | Coal, wood, oil, gas | Round type/cylinder | Rotation pyrolsyis | environmental | Need to cool down to slag |

Fully continuous | Auto-feeder | Indirect | Oil,gas | Cuboid/rectangular | Static pyrolsysis output oil with less dust, oil with better quality | Less dust, more environmental | No need to cool Saving fuel and working time |

Working details:

batch type:

one day one batch, day time heating pyrolysis, night time cooling .

semi-continuous type:

First time feeding 10Ton and heating, after 8 or 6 hours feeding second time 6 Ton and heating and pyrolsyis for another 6 hours

then feeding third time 4 Ton . And continue heating, after 5hours, this 5 Ton raw material complete pyrolsyised ,then cooling down reactor , and slag out. Semi-continuous pyrolysis means feeding 3 times (intermittent) and slag one time.

Compare to batch type, this semi-continuous plant just add auto feeder. this is not real meaning continuous.

fully continuous pyrolsysis,

continuous feeding without stop and the plant running 24hours*26dayst untill plant overhual.

continuous feeding , and continuous slag out.

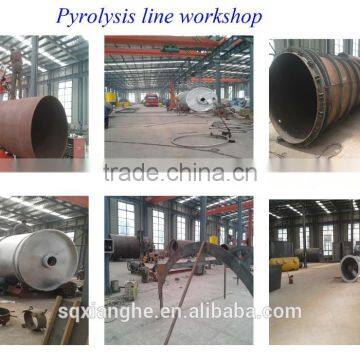

6.Avout us

Shangqiu Harmony Machinery Manufacturting Co.,LTd. is a professional manufacturer engaged in the research, development, production, sale and service of Environmental machines, waste tire/rubber/plastic pyrolysis equipment, waste oil distillation machines, etc.

We have rich experience(8 years experience) in making and installation shangqiu harmony is the top 10 enterprise in disposing waste rubber and plastic and has been cooperated with one South Korea company to dispose waste plastic . The company has gained rich experience and achievement in processing waste solid. This project in dealing with city living waste has been approved by South Korea government and the continuous equipment has been under testing in Korea. The production line of processing level 2 waste tyre with automatic control has been under testing in Hong Kong.

our products are:

Pyrolysis plant | Type | Daily capacity | Used for | Final Product and usage |

Batch type | 3ton 5Ton 10ton 12ton 15ton 20ton | Waste tyre Plastic Rubber Oil sludge Oily waste Others |

Fuel oil

Used for heating boiler as furnace oil Or refined for distillation oil | |

Semi-continuous type | 15Ton, 20Ton | |||

Fully continuous type | 20ton 30ton 60ton | |||

Special type | 20Ton 15ton | |||

Distillation plant |

Fully continuous type | 3ton 5ton 10ton 15ton 20ton 30ton 40ton

| Used motor oil Used lube Washing parts oil Pyrolysis oil Crude oil Others

| A.. base oil for heavy vehicles

B. diesel for car and other |

CUSTOMERIZE PLATN ARE WELCOME

Send Inquiry to This Supplier

You May Also Like

-

WL-1600 Garbage Shredder Household Waste Shredder MSW Recycling AmchineUS$ 55000 - 98000MOQ: 1 Set

-

High Efficiency Jinzhen 1~12 Ton Waste Plastic Pyrolysis to Crude Oil EquipmentUS$ 15,000 - 48,000MOQ: 1 Set

-

Rubber Powder Grinding Machine, Rubber Tire Recycling Machine for SaleUS$ 1,800 - 5,500MOQ: 1 Set

-

Forklift Solid Tire Press Machine 80T 100T 120 TUS$ 16 - 200MOQ: 1 Piece

-

High Output Bead Wire SeparatorUS$ 1,000 - 5,000MOQ: 1 Set

-

Fully Automatic Recycling Machine for Rubber PowderUS$ 34,000 - 114,000MOQ: 1 Set

-

In Stock Waste Tire Pyrolysis Plant for Tire OilUS$ 35,000 - 50,000MOQ: 1 Set

-

High Quality Hydraulic Car Tire Compress MachineUS$ 73,800 - 98,000MOQ: 1 Set

-

Salable PS Foamed Sheet ManufacturerUS$ 1,000 - 50,000MOQ: 1 Set

-

Rubber AccessoriesNegotiableMOQ: 1 Set