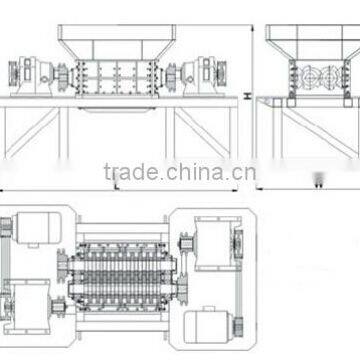

Plastic Bottle Cutting/slicing Scrap Metal Cans Shredding Machine

plastic bottle cutting/slicing scrap metal cans shredding machine (whatsapp:+8615937198193)

1. Q: How did your machine work ?

A: The main components are a relative rotation of the roller, the roller success teeth tops spirally arranged. After the material into the machine by the teeth staggered rotation of high hardness and wear-resistant material shear pull bite is split, broken and crushed to less than the set size after being forced to exclude outside. Roller driven by a motor through reducer having a large torque encountered difficulties debris, it will automatically reverse the role of PLC automatic control system, and repeatedly reversing, until the material is broken exhaust.

2. Q: What raw material of your machine are suitable for ?

A:

3. Q: Final size scope of your machine support after crushing ?

A: This kind of industrial shredder machine is designed for coarse smash , the width of final slice support 3-10cm and length can be customized per clients request .

4. Q: What is the purpose for crushing ?

A: Increase bulk density of raw material to help save transportation cost and space , or improve the handling capacity on further fine grinding

5. Q: what is the features of your scrap metal cans shredding machine ?

A: frame plate thick , low speed, high torque

electrical control cabinet (with function buttons for "on , off , reverse and overload automatic reverse ")

knives are made of alloy steel casting, 55sicr material (other options for 9crsi, and cr12mov , and mainly depends on user' request )

6. Q: What is the specification for your all models ?

A:

| Model | Feeding Hole (mm) | Max feeding size(mm) | Discharging Hole(mm) | Handling Capacity | Power(KW) | Wt(ton) | Dimension(L*W*H) |

| HDSS-600 | 500*600 | 85 | 10-40 | 0.5-0.7 | 18.5 | 2.2 | 1720*660*1850 |

| HDSS-800 | 700*800 | 100 | 10-50 | 1-1.2 | 30*2 | 3.6 | 1910*850*1990 |

| HDSS-1000 | 900*1000 | 120 | 14-70 | 2.5-3 | 75 | 6.5 | 2000*1070*1990 |

| HDSS-1200 | 1000*1200 | 150 | 20-60 | 3-3.5 | 90 | 10 | 2400*1090*2270 |

| HDSS-1600 | 1400*1600 | 160 | 20-100 | 3.5-4.5 | 132 | 19 | 2400*2200*3500 |

| HDSS-1800 | 1800*2000 | 180 | 30-100 | 7-8 | 180 | 30 | 2500*2400*5200 |

7. Q: What service you can provide after we bought your scrap metal cans shredding machine ?

A:

Before sending the machine , we will test , for any problems , we will find timely and moreover make approprite adjustment , speak from this aspect , we can guarantee each machine comes in 100% good quality , and you can use directly after connect with electric power

Operating video will be sent to clients together with instruction book , to help them for a better use.

Any Problems occurred while running , professional advice(technic support) will be given by us within 24 hours via email

Ware parts of hammer , blade and screen mesh are supplied from us all the year round .

One year guarantee for whole machine except spare parts .

8.Q: Will you show us some photos to see your crushing effection ?

A:

9. Q:What quick-wear part this machine include ?

A : sieve and blade

10. Q : Will you share us your company info ?

A : We are a trading company , but now only cooperate with several fixed machinery factory which produce good quality equipment . In past three years , with more and more understanding on product knowledge in the whole(true) communication process , and naturaly we will give up the low credibility and poor quality supplier , so.....choose us as a partner , firstly means that you are guaranteed on machine performance . As for that price , maybe we are not the lowest , but I am sure we are the best as dealed . To give you a reference , here as below I show you the main production line we are versed in :

- tradtional squeezing edible oil + refining

- steel wire nail

- sawdust briquetting

- fruit /tuber vegetable cleaning( peeling) + cutting+ dehydration oven + vacuum package (Nitrogen Filling)

- tofu machine

- coffeen bean roaster + grinder (also applicable for various seasoning , sugar , salt and etc )

- waste vehicle oil purifier processing recycling equipment for getting oil and metal pieces

- motor rotor crushing separating machine

11. Q: How should I contact you ?

A: pls find below photo.

12. Q : What information we should provide for getting a quotation on suitable model ?

A: 1. show me the photo of your raw material ? And moreover advise its biggest size ?

2. what final size you required after shredding ?

3. what handling capacity you asked per hour ?

13.Q: How we can get to your factory for a visiting ?

A: XINZHENG INTERNATIONAL AIRPORT is the nearest one from us , you can fly there and then we pick up you .

If you take the bullet train , our nearest station is GONGYI NAN .

14. Q: How long time of your spare parts can use ?

A: it is not fixed , mainly depends on the hardness of your raw material , generally comes between 6-12 months .

Send Inquiry to This Supplier

You May Also Like

-

Crushing More Than 100 Kinds of Solid Metal Materials Metal Crusher MachineUS$ 1 - 999999MOQ: 1 Set

-

Fully Automatic Plastic Crusher, PET/PP Plastic Shredder, Small Plastic Crusher Price.US$ 1450MOQ: 1 Combo

-

Wood Pallet Crusher Single Shaft Crushing ShredderUS$ 11500 - 15800MOQ: 1 Set

-

Beverage Cans Multiple Shredder Big Blue Barrel CrusherUS$ 5333 - 53333MOQ: 1 Set

-

Plastic Shearing CrusherUS$ 20,000 - 80,000MOQ: 1 Set

-

NEW Waste Plastic Grind MachineUS$ 5,000 - 10,000MOQ: 1 Set

-

Solid Waste Shredding MachineUS$ 1,000 - 5,000MOQ: 1 Set

-

High Performance Powerful Recycling Machine Plastic CrusherUS$ 1,500 - 20,000MOQ: 1 Set

-

Professional PET Flakes PET Plastic Crushing and Washing MachineNegotiableMOQ: 1 Set

-

Rubber SealNegotiableMOQ: 1 Set