Specifications

Lime Rotary Kiln1. Easy to operate

2. Strict quality control system

3. Convenient maintenance

4. With ISO9001

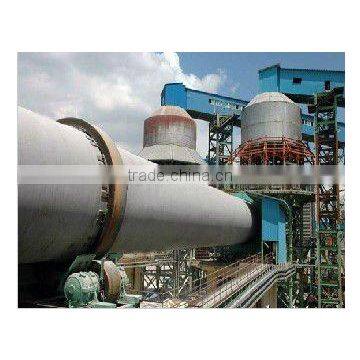

Best Performance and High Efficiency Lime Rotary Kiln

Brief Introduction of Lime Rotary Kiln: |

Lime rotary kiln belongs to building material equipment, which can be divided into cement calcination kiln, metallurgy chemical calcination kiln and lime calcination kiln according to different materials. Cement calcination kiln is used for making of cement clinker and there are dry and wet methods to make cement. metallurgy chemical calcination kiln is used in metallurgy industry and ironworks for lean iron ore, chromium ore and ferronickel ore calcimine. Lime rotary kiln is used for calcimine of high aluminum vandal ochre in refractory material industry, calcimine of calotte and aluminum hydroxide in aluminum manufacturer, claiming of chrome sand ore and chrome powder ore in chemical plant.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Features of Lime Rotary Kiln: |

1. Low pressure drop pre heaters.

2. Raw mill equipped with High efficiency separator.

3. Raw Meal blending in CFC silo.

4. Pre calciner suitable to work with alternative fuels.

5. Inlet & discharge fitted with efficient seals.

6. Benchmark cooler design.

7. Low Fuel Consumption.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Application of Lime Rotary Kiln: |

The Lime Rotary Kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary calcination kilns include: Cement

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Working Principle of Lime Rotary Kiln: |

1) With a certain slope to the level, the whole kiln body is supported by rollers and fitted with thrust rollers to control up and down movement of the kiln body.

2) Besides main driving unit for driving system, it is also fitted with the auxiliary driving unit so as to ensure the kiln body still can rotating when the main motor is powered off and prevent it from deforming.

3) The kiln head adopts housing type sealing and kiln rear uses axial contact sealing unit so that reliability of sealing could be ensured.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main Technical Parameter of Lime Rotary Kiln: |

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pictures of Lime Rotary Kiln: | | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Send Inquiry to This Supplier

You May Also Like

-

Multi-function Powder Mixing Equipment Stainless Steel U-typed Powder Blender Flour Double Screw Mixer With CEUS$ 880 - 2290MOQ: 1 Set

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Factory Supply Cco Plate Mixed Concrete Batching Plant Wear Resistant LinersUS$ 500 - 500MOQ: 1 Set

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set