Cooling jacketed beer fermenting equipment

This Fermentation Tank( seed tank, crystallizing tank) is widely applied in beer fermentation,beverage, pharmacy, fine chemical engineering and biological engineering industries.

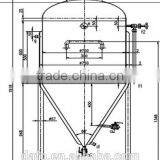

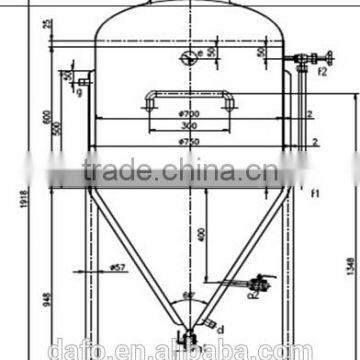

1) The tank body has interlayer and heat-insulating layer (for heating, cooling or heat insulating) The tank body, upper and lower closure heads(or taper) all adopt spinning R-angle processing. The internal wall of the tank has got mirror polishing with finish Ra≤0.4μm.

2) It has no sanitary dead corner and its wholly-enclosed design ensures that materials are always mixed and ferment at non-pollution state.

3) It is equipped with devices including air respirator, cleaning ball, sanitation inlet, viewing mirror, and viewing lamp. The fermentation process of Pharmacy, fine chemical engineering and biological products is aseptic and untainted.

4) Fermentation tank adopts aseptic system which helps avoid microorganism pollution in the air and greatly extends quality warranty period and purity of the products. We specially designed and installed aseptic respiratory air hole or aseptic normal-pressure fermentation system, which can finish circulating heat-up and cooling through medium heat-up and cooling.

The parts that contact materials are all made of stainless steel SUS304 or SUS316L. Heat preservation adopts polyurethane blister or pearl cotton. External surface adopts sand grinding surface polishing treatment. All is in accordance with GMP standard. Volume has different specifications ranging from 100-50000L.

Use mill to smash the grains,then transfer to brewhouse.

The brewhouse including the mash/lauter tun,boiling/whirlpool tank and hot water tank if necessary,these parts also have different combinations.

Then the wort will go through the exchanger for cooling down and then to fermenters for fermentation process.

Our beer can be drinked in the fermenters,if need to filling inside the bottles or kegs,need the filter and filling system.

1.PRODUCTION INFORMATION

| Description of goods | BEER FERMENTATION |

| Capacity | customized |

| MOQ | 1 PC,THE MORE THE CHEAPER |

| Lead time | 30 days,based on your demand |

| Packaging | exporting standard wooden case,up to you. |

| Payment | T/T,L/C, Western Union |

| Supplying ability | More than 500 pcs per year,based on the capacity |

| Port of loading | NINGBO |

| Trade term | FOB,CIF |

| Material | FOOD GRADE S.S.304 |

2.TECHNICAL SPECIFICATION

| Inner surface | S.S.304,WELL POLISHED,polishing precision≤0.4µm,THK:2-4mm |

| Outside surface | S.S.304,frosted or mirror,THK:1.5-3mm |

| Top shape | Seal head or conical head |

| Conical degree | 60-90°c |

| Manhole location | Side upward/side/flanged |

| Insulation | Material:PU,THK:50-100mm |

| Cooling jackets | DIMPLED cooling jackets at bottom and side wall. |

| Spray ball | Located in the center of inside of the tank |

| Pressure | 0.2MPa |

| Thermometer | Bi-metal thermometer |

| Legs | 3/4 round legs,can designed to be adjustable |

| The ratio of working volume to gross volume | 4/5 |

| Operational method | Automatic or manual |

| Technology processing | Argon-arc welding,well weld in double sides. |

Pre-sale service:

1. Free of making offers, craft and technical guidance.

2. We can provide company’s qualification certification and the drawings.

3. We can also make customized products according to customer’s needs.

After-sale service:

1. We provide long-term after-sale service.

2. Meanwhile, you can call or e-mail to consult any relevant questions since we have a special line of after-sale service. Or you can communicate online and solve the problems.

Advanced Technology Co., Ltd Wenzhou is the a professional beer equipment and brewing technology supplier, who can professionally design, research and develop, and manufacture the brewing equipment. we can provide clients one-stop service from design, layout, to finished products. Its main business includes beer equipment, self brewing equipment, hotel beer equipment, draft beer dispenser, school laboratory equipment, etc. We mainly provide the capacity 500L/DF, 1000L/DF, 2000L/DF, 3000L/DF, 5000L/D etc.

Our staff of sales and technical support is available to help you in selecting the right protection for your application as well as to provide you with samples of our products for evaluation. At Advanced Tech., we are committed to providing the highest level of customer service, competitive pricing, speedy delivery and a comprehensive, cutting-edge product offering. Our ultimate goal is your satisfaction.

We have got CE, PED, ISO9001 (2008) certificates. If necessary, we can offer electronic record’s certificates but the original document must be kept in the company.

Shipment

Bulk cargo: standard wooden case which can avoid any clash during the sea or air transportation in case of causing damage to the equipment’s surface.

Container cargo: equipment will be bound firmly,won’t easily swing to the side, or up, or down.

Send Inquiry to This Supplier

You May Also Like

-

Wheat Coffee Bean Roaster Electric Gas Heating Peanut Nuts Corn Coffee Roasting Machine Oil Making Production Line EquipmentNegotiableMOQ: 1 Set

-

Wine Fermentation TankNegotiableMOQ: 1 Set

-

Supply OEM/ODM Bean Sprout MachineNegotiableMOQ: 1 Piece

-

Heavy-Duty 4m High Basketball Court Fence With Anti-Climb DesignNegotiableMOQ: 1 Acre

-

2019 Shanghai Genyond Small Scale Commercial Tofu Production LineNegotiableMOQ: 1

-

Peanut Cutting Machine Almond Strip Cutting Machine Fast Cutting SpeedNegotiableMOQ: 1 Set

-

Factory Price Bean Bud Seedling Machine/Bean Sprout Growing Machine For SaleUS$ 1,500 - 7,999MOQ: 1 Set

-

Large Output Sprouts Cleaning Machine Vibration ShellerUS$ 1 - 2,500MOQ: 1 Set

-

Professional Manufacturer of Soybean Milk Process MachineUS$ 1,500 - 3,000MOQ: 1 Set

-

Green Bean Sprout Making Machine/machinery/makerNegotiableMOQ: 1 Set