Plastic Small Egg Tray Making Machine

Welcome to Zhengding Pantao Machinery Factory!

We are looking forward to cooperate with you!

1000 PCS/H Egg Tray Machine:

Product Description:

Oprating principle:

The egg tray forming machine makes trays by reciprocating. And 3 pieces once,1000 pieces per hour.

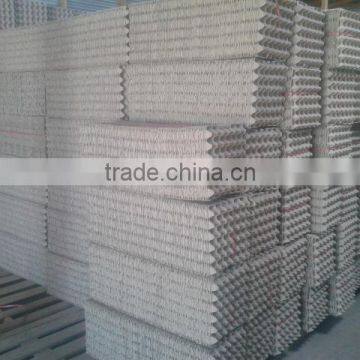

And it can make egg trays, egg boxes, apple trays, meat portion trays, vegetable portion trays, fruit portion trays, wine packs, can trays, seed pots, seed cubes, shoe stretcher etc.

Product Process:

A. Put raw materials into the pulper, add water and stir the pulp.

B. The forming machine makes egg trays.

C. Transmit the finished egg trays from forming machine to the dry hole by a conveyor. And dry them.

D. Put in order and package egg trays.

Introductions:

1. Raw materials: (for step 1)

A. Pulp Board

Different pulp made by bulrush, straw, bagasse, bamboo, wood etc.

B. Waste Paper

Such as paper board, carton, newspaper, magazine, waste pulp.

C. Plant Fiber

Palm fiber, straw fiber, sugarcane fiber etc.

2. Configures:

For step 1: Hydrapulper, Pulp Pump,

For step 2: Air Compressor, Agitator, Self Priming Pump, Pulping Machine. Egg tray Forming Machine, Vacuum Pump, High Pressure Washer, Pressure Tank, Mould, Transfer Mould, Baler,Low Vacuum Filling Machine.

For step 3: Induced Draft Fan, Conveyor, Fan, Mesh Bag Actuator, Dry Iron Roller, Mesh Belt Slide, Mesh Belt Bag.

3. Drying methods: (you can choose the best one which fits your order)

Single Brick Drying Line.

Single Metal Drying Line.

Multi Metal Drying Line.

4. The machine needs 5 labors to operate it.

The basic information:

The advantage of PT-1000B:

1. Operate easily.

2. Better product quality

3. Factory price

4. Excellent after-sales service

5. Engineer available to service machinery overseas

About the company:

It is for 20 years that our factory has been making egg tray machine. We have experience and professional technology in the field where to produce the egg tray forming machine. Besides, our engineers will service machinery overseas until the clients get how to operate it.

Not only does our factory produce 1000 pcs/h, 2000 pcs /h, 2500 pcs/h, 3000 pcs/h, 3500pcs/h, 4000pcs/h, but also make any type machines to clients orders.

One year warranty! High quality!

Waiting for your contact!

Send Inquiry to This Supplier

You May Also Like

-

Books Hard Cover Cutter Magazine Glue Cover Removal Papers Spine Cutting MachineUS$ 1500 - 2250MOQ: 1 Set

-

Automatic Rotary Egg Tray Equipment / Egg Tray Production LineNegotiableMOQ: 1

-

Automatic Paper Recycling Machine for Produce Craft Paper From Www.frdpapermachine.comNegotiableMOQ: 1 Set

-

Toilet Paper Cutter/Kitchen Towel Cutting Machine Price With High PerformanceUS$ 1,500 - 2,000MOQ: 1 Set

-

2020 New Fabric Roll Strip Slitting Cutting MachineUS$ 3,200 - 4,200MOQ: 1 Set

-

Paper Tray Forming Machine That Make TraysUS$ 10,000 - 20,000MOQ: 1 Set

-

1092mm Paper Wideth 4-5 T/d Capacity a4 Printing Paper Making MachineUS$ 20,000 - 150,000MOQ: 1 Set

-

Waste Paper Recycled Egg Tray Making MachineUS$ 7,000 - 7,000MOQ: 1 Set

-

Mechanical Screening Equipment 0.6M2US$ 2,000 - 20,000MOQ: 1 Unit

-

High Speed Automatic Paper Feeding A4 Office Paper Cutting MachineUS$ 10,000 - 135,000MOQ: 1 Set