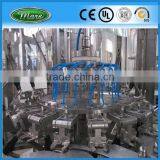

Mineral Water Pure Water Filler

Introduction:

This filling machine contains washing, filling and capping with complete automation. It is suitable for filling water, such as mineral water, pure water into polyester bottles and PET bottles. The bottleneck blocking makes the process of changing bottles easily by only adjusting the height of the conveyor chain. The filling process adopts micro-pressure technology, which makes filling process faster and more reliable

Main Parameters for Mineral Water Pure Water Filler :

Model | CGF12126 | CGF18186 | CGF24248 | CGF323212 |

Heads of washing,filling, sealing | 12-12-6 | 18-18-6 | 24-24-8 | 32-32-12 |

Production capacity | 3000-4000BPH | 5000-7000 | 8000-10000 | 10000-12000 |

Suitable bottle diameter | φ=50-100mm, H=170mm, 330-2500ml | φ=50-100mm, H=170mm, 330-2500ml | φ=50-100mm, H=170mm, 330-2500ml | φ=50-100mm, H=170mm, 330-2500ml |

Spraying pressure | 0.2-0.25Mpa | 0.2-0.25Mpa | 0.2-0.25Mpa ³ | 0.2-0.25Mpa |

Motor power | 2.2kw | 2.5kw | 3kw | 5.5kw |

Stainless steel | SS304 | SS304 | SS304 | SS304 |

Electric voltage | 380V50Hz | 380V50Hz | 380V50Hz | 380V50Hz |

PLC | Mitsubishi | Mitsubishi | Mitsubishi | Mitsubishi |

Frequency converters | Mitsubishi | Mitsubishi | Mitsubishi | Mitsubishi |

Touch screen | Mitsubishi | Mitsubishi | Mitsubishi | Mitsubishi |

Circuit contactor | Siemens | Siemens | Siemens | Siemens |

overall dimension | 2400*1600*2500 | 2500*1800*2500 | 3100*2300*2800 | 3800*2800*2900 |

Weight | 2500kg | 3500kg | 4500kg | 6500kg |

Main Features for Mineral Water Pure Water Filler:

1.Air Conveyor connectes with bottle-in starwheels. Bottle neck holding transferred.

2.Clamp transferring technology varied bottle types.

3.With little abrasion. Stable Transferring. Easy to change bottles.

4.With ring type pressure bearing hydraulic cylinder.

5.With high filling speed and exact liquid level.

6.Excellent Stainless Steel. Electric Components are of world known brand. All achieve national sanitary standard.

7.The bottle-out starwheel is of screwdown shape. No need to adjust transferring chain's height to different bottles. 8.Easy to operate and maintain.

9.PLC and transducers and othe main electric parts are of world famous brands, such as OMRON, MITSUBISHI etc.

Send Inquiry to This Supplier

You May Also Like

-

Automatic Spice Powder Grinding Machines Salt and Peeper Grinder Nut Grinder Machine for Food ProcessingUS$ 620 - 1060MOQ: 1 Set

-

Big Bags 1 Ton Jumbo Bag Powder Granule Packaging Machine FIBC Weighing Filling StationUS$ 1 - 48000MOQ: 1 Set

-

Auto Bottled Water Filling And Capping MachineNegotiableMOQ: 1 Set

-

GNEYOND Protein Powder Filling and Seaming Line Milk Powder Tin Can Filling Sealing MachineNegotiableMOQ: 1 Set

-

Pyramid Tea Bag Packing Machine|Tea Sachet Packaging MachineNegotiableMOQ: 1 Set

-

China Small Beverage Bottle Wrapping Machine /juice Bottle Packing Machine/shrink Packing MachineUS$ 4,000 - 10,000MOQ: 1 Set

-

Flexible Permanent Neodymium Ball Magnets Colorful Magnetic Bucky BallsNegotiableMOQ: 1 Set

-

LCS-10/50LY Double-auger, With Weighing Bucket, Automatic Weighing Packing MachineUS$ 1 - 500MOQ: 1 Set

-

ALGFM-1 Popular Automatic Packaging Machines for GrainUS$ 1 - 6,000MOQ: 1 Set

-

Factory Price Bottled Tomato Paste Filling MachineNegotiableMOQ: 1 Set