Juice Filling Production Line / Fruit Puree Machines

Juice processing line

Features:

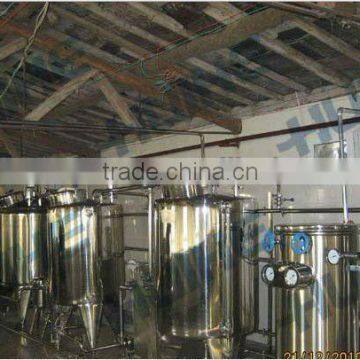

This fruit juice processing plant can be used for making all kinds of fruit juice. All the equipments are made of 304 stainless steel which is durable and clean. All the standard connecting pipes are made of 304 stainless steel, customers can also choose PVC pipes. The whole system is full automatic. There is automatic electric control system. It just needs a few operators to handle the plant.

Main equipments:

juice extractor, water treatment plant, CIP cleaning system, sterilization machine, mixing tank, filling equipment.

Characteristics:

1. it can carry out washing pulp filling, liquid juice filling and capping in one machine.

2. it is very convenient to change diverse sizes of bottles by means of advanced bottle neck clamping & bottle suspending technology.

3. Advanced programmable PLC is equipped to control the main machine. Working speed can be adjusted by frequency conversion device.

4. Main electronic components are all from famous international enterprises, such as OMRON, Mitsubishi.

Technical parameters:

Model | HGF-14-12-5 | HGF-18-18-6 | HGF-24-24-8 | HGF-32-32-10 | HGF-40-40-12 |

Capacity | 3000b/h | 6000b/h | 10000b/h | 14000b/h | 18000b/h |

Bottle size | Diameter: 50-100mm Height: 150-320mm | ||||

Applicable cap | Plastic screw cap | ||||

Washing pressure | 0.18Mpa | ||||

Air pressure | 4Mpa | ||||

Air consumption | 0.2m³/min | 0.3m³/min | 0.4m³/min | 0.5m³/min | 0.6m³/min |

Power | 4.23KW | 5.03KW | 6.57KW | 8.07KW | 9.6KW |

Weight | 2500kg | 3000kg | 4000kg | 5000kg | 6000kg |

Dimension | 2300×1550×2500mm | 2640×1800×2500mm | 3000×2000×3150mm | 3600×2800×3150mm | 4500×3400×3150mm |

Other Features:

a).The three functions of bottle washing,fill and seal are composed in one body of the machine.

b).The whole process is automatic.

c).The machine is used in filling juice,mineral water and purified water in bottles made of polyester and plastics.

d).The machine can also be used in hot filling if being instealled with temperature controlling device.

e).The handle of the machine can be freely and convenently turned to adjust the machine to fill various types of bottles.

f).The filling operation is faster and more stable because the micro pressure filling operating of the new type is adopted.

g).There the output and benefit of the machine is higher than the machines of the same specifications.

h).The advanced programmed controller(PLC)is adopted to control the machine to run automatically while the using wind is used in the bottle-entering chains to adjust speeds and coordinated with the transducer of the main machine to make the operations of moving bottle forward steadily and reliably.

i).It is convenient to operate with higher automation because every prt of the machine is inspected to run with photo electricity.

On the bases,the filling parts of the machine can be changed into filling methods of lower vacuum.The machine is an idea-preferred equipment for beverage makers!

Send Inquiry to This Supplier

You May Also Like

-

Portable Vegetable and Fruit Dryer for Camping and Outdoor Activities With Compact SizeNegotiableMOQ: 1 Set

-

High Quality CBD Oil Co2 Supercritical Extraction MachineNegotiableMOQ: 1 Set

-

Automatic Vegetable Dicer Potato Dicing Machine for Cutting Potato Cassava TomatoNegotiableMOQ: 1 Set

-

Food Drying Oven Heat Pump Drying OvenUS$ 3800 - 4500MOQ: 1 Piece

-

Chinese Suppliers Automatic Size Sorting Color Sorting Cherry Sorting MachineNegotiableMOQ: 1 Set

-

Industrial Grade Vegetable and Fruit Dryer Compatible With Food Processing Systems for AgricultureNegotiableMOQ: 1 Set

-

Commercial Vegetable and Fruit Dryer for Horticulture Applications and Large-Scale FarmingNegotiableMOQ: 1 Set

-

Energy-Efficient Vegetable and Fruit Dryer Featuring Low Power Consumption and Digital ControlsNegotiableMOQ: 1 Set

-

User-Friendly Vegetable and Fruit Dryer With Easy Cleaning Features and Durable Material ConstructionNegotiableMOQ: 1 Set

-

Multi-Layer Vegetable and Fruit Dryer With Variable Speed Fans for Efficient DehydrationNegotiableMOQ: 1 Set