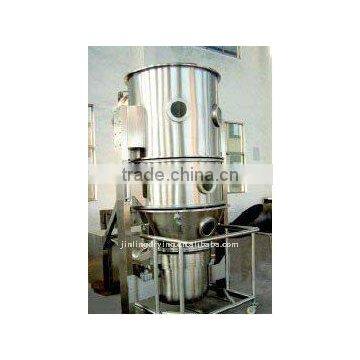

FL Fluid Bed Granulating Machinery (one Step Granulator)

Specifications

1.FL fluid bed Granulating Machinery2.Granulating and drying in one step,

3.Widely used

4.GMP

Applications

FL fluid bed Granulating Machine is mainly used for the operations of granulating and drying of granule Top Spraying, etc of powder material in pharmaceutical industry, foodstuff industry, chemical industry, etc. Such as granule of tablet, granule for quick resolving drinking, condiment

Principle

The powder material is in a boiling state in fluid bed, heated and mixed by filtered hot air. Then spray binder into fluid bed, make the dry powder material agglomerate and become granules. The moisture in granule is evaporated by hot air and binder is solidified. Finally, the ideal, uniform and porous finished granule will be got.

Features

Because of powder granulating, the flow property is improved and the dust is reduced.

Because of powder granulating, its solving property is improved.

The mixing, granulating and drying could be completed in one machine.

Being adapted anti static filter bag, the operation is safe.

There is explosion releasing hole to keep the people’s security when explosion.

The equipment has no dead corner, easy for feeding, discharging and clean. It could meet the requirement of GMP.

Technical Parameters

| item | specification | ||||||||||||||

| name | unit | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | All sizes are used for reference only. According to the condition of material our factory has the right to change but not notice, pardon. | |

| container Volume | L | 12 | 22 | 45 | 100 | 155 | 220 | 300 | 420 | 550 | 670 | 1000 | 1500 | ||

| capacity | kg/ batch | 3 | 5 | 15 | 30 | 45 | 60 | 90 | 120 | 150 | 200 | 300 | 500 | ||

| steam | pressure | Mpa | 0.4-0.6 | ||||||||||||

| consum ption | kg/h | 10 | 18 | 35 | 60 | 99 | 120 | 130 | 140 | 161 | 180 | 310 | 400 | ||

| power of fan | kw | 2.2 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 22 | 30 | 45 | ||

| power of electricity heater | kw | 6 | 9 | ||||||||||||

| noise | dB | No more than 75dB separated of fan | |||||||||||||

| comp ressed air | pressure | Mpa | 0.6 | ||||||||||||

| consum ption | m3/ min | 0.3 | 0.3 | 0.6 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 0.9 | 1.1 | 1.3 | 1.5 | ||

| installation size for reference | H1 (mm) | 2600 | 2600 | 2100 | 2250 | 2250 | 2850 | 2850 | 2850 | 2850 | 3300 | 3500 | 3850 | ||

| H2 (mm) | 250 | 320 | 420 | 490 | 490 | 590 | 640 | 690 | 790 | 890 | |||||

| H3 (mm) | 1900 | 2050 | 2050 | 2600 | 2600 | 2600 | 2600 | 3000 | 3280 | 3630 | |||||

| B1 (mm) | 1550 | 1650 | 1010 | 1160 | 1320 | 1460 | 1560 | 1660 | 1760 | 1860 | 2060 | 2260 | |||

| B2 (mm) | 1650 | 1800 | 2060 | 2460 | 2660 | 2800 | 3060 | 3260 | 3660 | 4060 | |||||

| 1 (mm) | 300 | 400 | 550 | 700 | 860 | 1000 | 1100 | 1200 | 1300 | 1400 | 1600 | 1800 | |||

| 2 (mm) | 150 | 180 | 180 | 180 | 250 | 280 | 280 | 280 | 280 | 280 | 315 | 355 | |||

| L (mm) | 850 | 1000 | 1100 | 1250 | 1530 | 1530 | 1530 | 1650 | 1650 | 1650 | 1750 | 1 | |||

Send Inquiry to This Supplier

You May Also Like

-

GZP Automatic High-speed Rotary Tablet Press MachineNegotiableMOQ: 1 Set

-

JINHE Double Conical Pharmacy and Medical Dry MixerUS$ 2,000 - 15,000MOQ: 1 Set

-

Small Electronics Pill Capsule CounterUS$ 1,000 - 3,000MOQ: 1 Set

-

Popular Selling and Best Quality Pill Counting MachineUS$ 1 - 2,600MOQ: 1 Set

-

100PCS / TIME Smaller Tablet Counter Manual Tablet Capsule CounterUS$ 830 - 925MOQ: 1 Set

-

Rotary Vibrating Screen Sieving Machine for Small Gears, SprocketsUS$ 400 - 10,000MOQ: 1 Set

-

Industrial MixerUS$ 1,300 - 1,800MOQ: 1 Piece

-

Ginseng Cutting MachineUS$ 890 - 890MOQ: 1 Set

-

MAT TABLET MACHINENegotiableMOQ: 1

-

High Quality Stainless Steel Microwave Extracting Machine With Factory PriceUS$ 2,900 - 50,000MOQ: 1 Set