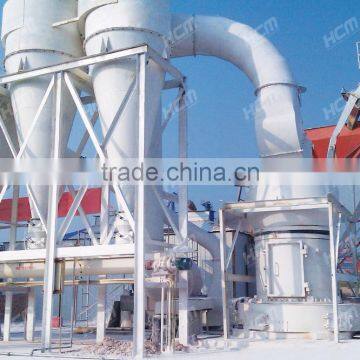

Energy saved stone powder making machine

Product Description

Product Application

HLM series vertical grinding mill a kind of advanced mill developed by HCM based on two decades of R&D experiences and introduction of foreign advanced technology. HLM Vertical mill is advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying. It is applied as a good solution to the technical issue such as low output, high energy consumption and high maintenance cost in ordinary industry.

HLM vertical mill has become the mainstream equipment in pulverizing industry with the following advantages: efficient grinding, lower powder consumption, large feeding size,adjustable fineness,simple process flow, space-saving,low noise,smaller air pollution, easy maintance, low operation cost,longer working life of wearing parts etc..

Limestone Calcite Dolomite

Vertical Mill Flow Sheet &Product Structure

Technical Advantages and Feature

1. Higher Efficiency

1) Higher grinding efficiency, lower powder consumption (40%~50% less than ball mill)

2)Higher production capacity, off-peak power can be used.

2. Easy Maintenance and Lower Operation Cost

1) The roller can be pulled out by the hydraulic device, which is convenience for plate-replacement and bigger maintenance space.

2) Left and right side of the roller cover can both used for prolonging the working life.

3) Without raw material on the grinding table, the mill can run,which erases the difficulty in starting.

4) The roller and grinding table are made from special material for longer working life.

3. Lower Investment

Combination of crushing, drying, grinding and conveying,simple process flow,reasonable and compact layout,space-saving(50%less than ball mill),lower foundation cost and workshop cost in the field.

4. Stable Powder Quality

1) Short-time stay of the raw material in the mill, which is easy for the powder fineness and

components analysis.

2) Regular powder shape, narrow size fineness, easy fluidity, extensive application.

5. Reliability

1) Roller with heigh-controlled device, which could avoid strong vibration called by the lack of material on the table.

2)Newly-designed roller sealing component ensures the reliable sealing without sealing the fan, which can lower the oxygen content in the mill to prevent the possibility of explosion.

6.Reliability

1) Lower vibration and noise

2) Perfect sealing and negative pressure gurantees no air pollution in the workshop.

3) Vertical mill is the better equipment to lower powder consumption in the mill industry,which is also

what the country advocate and a must to increase the enterprise competitiveness in China powder

industry.

7. High Automatic Level

PLC automatic control system, remote control,easy operation and maintenance, lower labor cost.

SUPPORT & SERVICE

Professional pre-sales and after-sales services ensure the high quality grinding mill running more smoothly and efficiently. Hongcheng has a professional, high efficiency and stable sales and service team and extensive sales and service network, which can provide our customers the most enthusiasm service and strong technical support worldwide.

Pre-sales Service:

1. Assistance in mill model selection

2. Guidance on workshop layout and site selection

3. Engineers to be at your place for free to do on-spot design and flow chart.

Mid-sales Services:

1. Perfect quality control system and strict inspection before delivery.

2. Assistance in providing logistics and on-time delivery.

After-sales Services

Free guidance on foundation-making

Free guidance on installation and testing

Free training in repair and maintenance

Professional after-sales team with 21 after-sales service offices in China and abroad, and 24*7 hours work per week.

Service Line: +86-138-2449-7223

Spare Parts

Amply supply of spare parts to meet customers’immediate needs.

CUSTOMERS’ SITE

CONTACT INFORMATION Guilin HongCheng Mining Equipment Manufacture Co., Ltd.

Send Inquiry to This Supplier

You May Also Like

-

Lab Mill Triple Grinding Machine For TestingUS$ 656 - 3,640MOQ: 1 Set

-

Ball Mill Jar With Capacity of 0.56-130TPH and ISO9001:2008 CertificateNegotiableMOQ: 1 Set

-

Mineral Gold Ore Copper Ore Complete Chrome Ore Processing Line for AlbaniaUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Gold Ore Wet Pan Mill /pan Mill /wet Grinder Made in HuahongUS$ 1,000 - 8,000MOQ: 1 Set

-

Hot Sale Carbon Black Grinding MachineUS$ 1,900 - 3,500MOQ: 1 Piece

-

China Bank Account OpeningNegotiableMOQ: 1 Set

-

KMJ02-05 Stone Grinding Ball MachineNegotiableMOQ: 1 Unit

-

China Top 10 Chocolate Ball Mill With Quality CertificationUS$ 5,000 - 60,000MOQ: 1 Set

-

China BV CE Certificates Mining Stone Impact Crusher Machine Manufacture SupplierUS$ 1,000 - 1,000MOQ: 1 Set

-

Vertical Roller MillUS$ 40,000 - 150,000MOQ: 1 Set