Specifications

mifi food machine1.Twin screw extruder

2.Capacity:100-150kg/h

3.Extruded and inflated technology

4. CE certificate

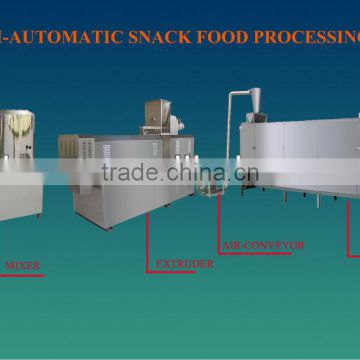

Mini Inflating Snack Food Making Machine

1. With the quickly pace of our national economic, people pay more and more attention to snack. Inflating food is increasingly recognized by people. After researching the habit of developed countries person and direction of leisure travel, our company develop this series of equipments. Its technologies have reached the European lever. This develop procession is from feeding materials, extruding, core filling, shaping, cutting, oil spraying to finish products are done once time automatic.

2. We fill the gap of the first-class food product with extruded and inflated technology. This processing line can produce all kinds of inflating foodstuffs, rice bread, core snacks, crackers, gruels, breakfast cereal baby food and so on. The raw material can be maize, rice or wheat flour, etc. The extruded food is good in taste, special in scent, digestible, easy to carry. It is wonderful leisure food for consumers.

Snack food processing line use advanced extruding technology,through changing moulds

andproductions technis to produce many kinds of popular snack food in market. It has a

agility scheme, strong adaptability,has gained good praise and agreement from public.

3. Parameter:

Parameter | Mixer |

Screw conveyor | Extruder | Air blower | Three-layer oven | Hoister | Oil spray | Flavor | Roller |

Model | BFJ-I | SLJ-I | LRS65-III | FSJ—I | HGD-3-II | TSJ

| DPY—II | TW | DGT—II |

Installed Capacity(kw)

| 3 | 1.1 | 34.75 | 0.75 | 30 | 0.75 | 2.37 | 0.37 | 0.75 |

Powe Consumption (kw) | 3 | 1.1 | 20 | 0.75 | 20 | 0.5 | 2 | 0.37 | 0.75 |

Output(kg/h) | 150 | 300 | 130-150 | 150 | 150 | 150 | 150 | 150 | 150 |

Dimension(m) | 0.9×0.6×1.2 | 2.5×0.5×2 | 1.7×0.8×2.3 | 1.3×0.5×0.6 | 5×1.3×2.1 | 1.3×0.5×0.6 | 1.0X0.6X0.8 | 2.3×0.8×1.3 | 2.1×0.8×1.3 |

4. Inflating snack food sample:

5.Factory show:

Wooden case which is suitable for long-distance transportation, multi-time loading and unloading for fork trucks.

- Lerun company will be provide factory layout according to customer’s factory size in advance.

- Our company will be sent an engineer to go your country and help client to install the processing line, train clients’ worker and teach client’s worker how to operate the machine.

- Additional, our engineer also teach client’s work how to clean the extruder, how to change the screw, how to clean the barrel etc, our company have responsibility to provide basic technology support with client.

- Engineer of Lerun company can provide basic formula for producing snack food and help customer to produce good quality snack food according customer’s detailed formula.

- Our company will be provide the spare parts will at preferentital price for an extended long time.

Send Inquiry to This Supplier

You May Also Like

-

Commercial Coffee Roasting Machine With Digital Controls for Specialty Cafes and RoasteriesNegotiableMOQ: 1 Set

-

Commercial Fried Ice Cream Roll Machine With Single Square Pan and Double Pan and Material BarrowsNegotiableMOQ: 1 Set

-

Waffle Cone Maker Ice Cream Cone Machine Ice Cream Cone Production LineNegotiableMOQ: 1 Set

-

Small Scale Automatic Yogurt Making Machine Yogurt Production LineNegotiableMOQ: 1 Set

-

Hot Hydraulic Car Brake Fluid DOT3NegotiableMOQ: 1

-

LS Electric Motor ScooterNegotiableMOQ: 1

-

Precision CNC Turned PartsNegotiableMOQ: 1 Set

-

3 Way Speaker FilterNegotiableMOQ: 1

-

Food Kiosk Kebab Trailer, Hot Dog Cart Mobile Food, Food Cart Manufacturer PhilippinesUS$ 1,200 - 2,500MOQ: 1 Set

-

21 Power-driven Chip Twister MachineNegotiableMOQ: 1 Set