Chemical Staple Fiber Production Machinery

STAPLE FIBER PRODUCTION MACHINERY

1. About us: CISSCO MACHINERY CO., LTD

Cissco Machinery Co., has been engineering and manufacturing a series of EXTRUSION MACHINERY for more than 10 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

2. General Introduction to our POLYESTER STAPLE FIBER MACHINE This production line can be used to produce polyester, polypropylene, polyamide and other staple fiber. Corresponding to technical equipment adjustment, it will be used to produce three-dimensional hollow fiber and other special chemical fiber.

The mainframe is diveded into two main parts, the prevenient filature and post filature.

3. Raw Material

4. Our Machinery process:

Two processes including:

4.1 fore spinning Line:

Vacuum Dryer -> Hopper -> Screw Extruder -> Filter -> Spin Beam (Meter Pump System, Spin Pack, Spinneret) -> Quenching Unit -> Interfloor Duct -> Draw-off Wall -> Capstan Roller -> Sunflower Gearing unit -> fiber can traverse system

4.2 after spinning Line:

if 2-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tow Stacker -> Crimper Steam Box -> Crimper -> Tow Conveyer -> Relaxer -> Tow Tension Stand -> Cutter -> Chain Plate Conveyor -> Baling Press

if 3-Dimensional Hollow Fiber:

Can Creel -> Inlet Thread Guide -> Tow Guide Stand -> Dipping Bath -> 1st Draw Stand -> Draw Bath -> 2nd Draw Stand -> Draw Steam Chest -> 3rd Draw Stand -> Tension Control Device -> Tow Stacker -> Crimper Steam Box -> Crimper -> Silicon Oil Sprayer -> Tow Tension Stand -> Cutter -> Fiber Spreader -> Fiber Leveler -> Relaxer -> Chain Plate Conveying system -> Baling Pressrecycled psf production line

5. Our process in Pictures

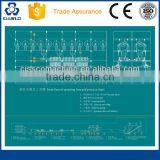

6. Layout , Configuration and Main parts

Note : The above production line is standard , different customers have different requirements , however we adjust the entire line according to our clients productions requests.

our wide knowledge in the production of Staple fiber allow us to carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

8. Our Service

• We design, engineer and manufacture and customized the extrusion line.

• Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

• Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our clients factory

• Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

9. Final Product

Loyal Luo, Sales Export & Business Developer

CissCo Machinery Co., Ltd.

Mob.: +86 18817937157 I Office: +86 2138726398 / 99

Email: market02@ I Skype: cisscomachine03 I Web:

Add.: 30B, No.58 New Jinqiao Road, Pudong, Shanghai, China

Send Inquiry to This Supplier

You May Also Like

-

Metal Portable Laser Welding Machine With Automatic ManipulatorUS$ 10000 - 30000MOQ: 1 Set

-

Contemporary Flocked Gift Box Packaging Fabric , Green Velvet Upholstery FabricNegotiableMOQ: 1 Set

-

Sell QuittingNegotiableMOQ: 1 Set

-

WARP TYING MACHINE WITHOUT LEASENegotiableMOQ: 1 Set

-

Lab Carding MachineUS$ 2,890 - 13,820MOQ: 1 Set

-

Best Price Ball Fiber MachineUS$ 1,900 - 5,000MOQ: 1 Set

-

Sisal Fiber Carder MachineUS$ 1 - 2MOQ: 1 Piece

-

Double Drawing Machine Rope Processing EquipmentUS$ 1 - 10MOQ: 1 Unit

-

Cylinder Carding Machine For BlanketUS$ 3,000 - 10,000MOQ: 1 Piece

-

Textile Machinery Rubber Calender RollersUS$ 10000.00 - 10000.00MOQ: 1 Piece