Kefan Professonal Cement Production Line Process Manufactor +0086-371-86678079

Specifications

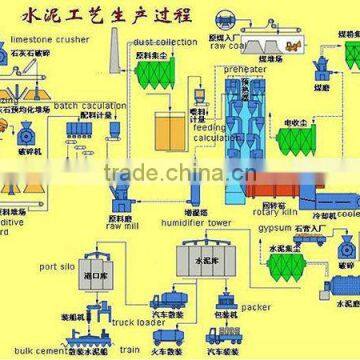

1)Raw material:limestone,clay,coal,etc.2)Feedin system--preheater system--kiln system--cooler system--products transfer system

Cement Production Line Process

In cement plant, ingredients for cement production go through the following several process.

1)Crushing and Preblending

In cement plant, most of the materials need to be broken, such as limestone, clay, iron ore and coal, etc. Limestone is the largest amount of raw material which is used in cement production line, but the size of raw limestone is large, and its hardness is high , so the limestone crusher plays a more important role in cement plant.

2)Raw material preparation

In cement plant, producing each 1 ton of cement needs grind at least 3 tons of materials (including raw materials, fuel, mixed materials, clinker and gypsum). Grinding operation consumes power about 60% of total power in cement plants, raw material grinding takes more than 30%, while coal mill used in cement palnt consumes 3%, cement grinding -about 40%. So choosing the right grinding mills in cement plant is very important.

3)Raw materials homogenization

Applying the technology of homogenization can rationally get the best homo-effect and afford an eligible production according to the demand.

4)Preheating and precalcing

Preheater and calciner is the key equipments for precalcing production technique.

5)Burning cement clinker in a rotary kiln.

The calcination of Rotary Kiln is a key step of cement production , which makes directly influence on the quality of cement clinker.

6)Cement grinding

Cement grinding is used for grinding cement clinker (and gelling agent, performance tuning materials, etc.) to the appropriate size (in fineness, specific surface area), optimizing cement grain grading, increasing the hydration area, accelerating the hydration rate to meet the requirements of cement paste setting, hardening.

7)Cement Storage & packing

Cement is a basic ingredient of concrete, mortar, stucco and most non-specialty grout. The cement is produced by grinding raw clinker which is making by limestone, clay, coke and gypsum. The grinding of cement clinker is a forward process. The clinker is put to feed hopper, which in turn feeds into the pre-crusher. Then the table feeders extract it out from the pre-crusher and put it into the ball mill. Finally, this fine powder is blended with gypsum which makes the cement.

Send Inquiry to This Supplier

You May Also Like

-

Multi-function Powder Mixing Equipment Stainless Steel U-typed Powder Blender Flour Double Screw Mixer With CEUS$ 880 - 2290MOQ: 1 Set

-

Trommel ScreenNegotiableMOQ: 1 Piece

-

Factory Supply Cco Plate Mixed Concrete Batching Plant Wear Resistant LinersUS$ 500 - 500MOQ: 1 Set

-

Supply 4*2 DFAC Light Truck Mixer Truck 6cmb Cement Mixer TruckNegotiableMOQ: 1

-

Solids Control Industry Desanding EquipmentNegotiableMOQ: 1 Set

-

Exported to Mongolia the Complete Cement Making LineUS$ 50,000 - 150,000MOQ: 1 Set

-

130T/H ROADY RD125New Asphalt Hot Mixing PlantUS$ 10,000 - 1,000,000MOQ: 1 Set

-

Polishing Machine RotomouldingNegotiableMOQ: 1

-

Automatic Ready Mixed Concrete Batching Plant Factory Concrete Admixture Mixing Plant New Technology Concrete Batch PlantUS$ 500 - 2,000MOQ: 1 Set

-

Good Stability & High Efficiency HZS50 Concrete Plant Twin Shaft MixerUS$ 50,000 - 150,000MOQ: 1 Set