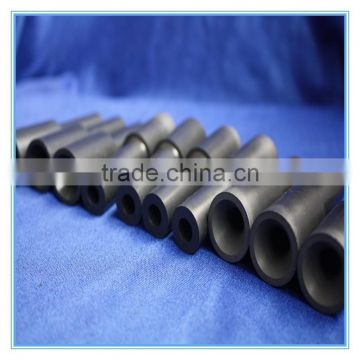

Furnace Blasting Carbide Nozzle/ Cemented Carbide Nozzle

Furnace Blasting Carbide Nozzle/ Cemented Carbide Nozzle

1. Item Description:

Tungsten/Carbide Nozzle |

Tungsten carbide nozzle/ Furnace Blasting is elaborated by precision machinery and carbide materials (superhard alloy) |

| Usage |

Cemented carbide with high hardness, wear resistance, good strength and toughness, heat resistance, corrosion resistance and a series of excellent properties, especially its high hardness and wear resistance, even at 500 ℃ temperature basic remains the same, there are still very high hardness at 1000 ℃.Hard alloy are widely used as a cutting tool material, such as turning, milling, planing tool, drilling, boring cutter, etc., used for cutting cast iron, non-ferrous metal, plastic, chemical fiber, graphite, glass, stone and ordinary steel, can also be used for cutting heat resistant steel, stainless steel, high manganese steel, tool steel and other hard processing material.. |

| Characterist |

Corrosion resistance, long service life, excellent performance, high performance-to-price ratio, is not easy to wear |

| Hardness |

More than 90 |

| Details |

Tungsten carbide nozzle is to use precision machinery and carbide materials (superhard alloy) and elaboration.The bending curvature of 2300 n/mm, degree of hardness of HRA90.When machining carbide nozzle, we achieve the precision grinding and surface treatment, realize the hole roughness for Ra0.1 and R, roughness on both ends for Ra0.025.At the entrance of the two There is a radius of curvature of the scientific design.This design can ensure the thread to go through.Due to the overall materials processing, there is no elevation in drilling, compared with the ruby nozzle, easy to bend and jams has improved |

| Features |

Tungsten carbide nozzle is made up of hot straight hole and QiuKong of hot pressing sintering.Because of its hardness, low density and excellent wear resistance and corrosion resistance, tungsten carbide nozzle has been widely used in sand blasting and shot peening equipment, guarantee the products in the best air and abrasive medium long time use |

| Density |

=14.89g/cm3 |

| Advantage |

Could customized as per your tolerence, size & proportion of ingredients

|

| Type |

Tungsten carbide nozzle hole determines the shape of the airflow patterns.Nozzle typically have a straight hole or limit hole, QiuKong |

| Grade | Density(g/cm3) | Hardness(HRA) |

TRS (N/mm2) |

Recommended Application |

| YG6 | 14.95 | 89.5 | 2580 |

Universal grade ,widely used in machining tools for cast ion,nonferrous metals and their alloys and nonmetal materials,wear parts ,and tools foe machining other alloys.

|

| YG8 | 14.74 | 89.0 | 2710 | |

| YG6X | 14.93 | 91.0 | 2480 |

Suitable for the semi-of hard cast iron,nonferrous metals and their alloys, and also suitable for the semi-finishing and of common cast iron and high manganese steel work-pieces and for othe tools

|

| YG6A | 14.89 | 91.5 | 2350 | |

| YG8C | 14.69 | 87.5 | 2850 |

Mainly used for rock drilling,auger tips and well drilling tools and at the same time for drilling stone walls,cemented construction and installation work,and machining stone materials.

|

| YG11C | 14.32 | 86.5 | 2940 | |

| YL10.2 | 14.45 | 91.5 | 2880 |

Mainly used for manufacturing strips and disc cutters and also for other tools

|

| YM80 | 14.76 | 90.5 | 2590 |

For manufacturing strips and also for other tools

|

| YS2T | 14.45 | 91.5 | 2380 |

Used for disc cutters and also for other tool

|

| YM15.1 | 14.05 | 92.5 | 2170 |

Suitable for the rough and of stainless steel, finishing of high strength steel sinishing and semi-sinishing of hardened steel ,and the machining of oron based heat resistant alloys and glass articles.

|

2.More item picture for your reference :

3. About Us :

Zhuzhou Good Cemented Carbide Co., Ltd. is a professional manufacturer of various tungsten carbide dies and cementsed carbide precision casting parts.We are equipped with advanced equipment and specialized persons,especially have rich experience in making products of complicated configureations.

Our Main products include tungsten carbide inserts,geoglogical and mining tools, drilling bits,crusching of carbide hammer ,precision casting parts, cutter tips, drawing dies,cold forging dies,new non-magnetic carbide mould,carbide bars,rods,balls,ware parts, ect.

We can also manufacture various cemented carbide tools as per drawing and samples based on different requirements of customers and provide whole package of solutions for machanical maching and manufacturing .

4.Why Choose Us:

- OEM & ODM available

- Quality Guarantee (ISO9001)

- Trial order acceptable.

- Short delivery time

- Good after-sale service

- Factory provide professional technical support & competitive price

- Various size for choose, customized as your drawing no problem

Send Inquiry to This Supplier

You May Also Like

-

Angle Grinder Universal Woodworking Tools Starlock SawbladesNegotiableMOQ: 20 Pieces

-

1/2 Inch Quick Change Hole Saw Arbor for Power ToolsUS$ 1 - 30MOQ: 648 Pieces

-

Tungsten Carbide Inserts to SpecificationUS$ 1 - 1.5MOQ: 100 Pieces

-

BladesUS$ 2 - 2.5MOQ: 5 Pieces

-

Masonry Router Bits For WoodUS$ 1 - 4.8MOQ: 100 Pieces

-

Modelling Ball Tools Double Sided Bone Carving Tools 8 Different Sizes IncrementsUS$ 1 - 100MOQ: 100 Pieces

-

Item No.: STA4252 Cutter&BladeUS$ 1.5 - 1.55MOQ: 2000 Sets

-

Non Sparking Tools,U-type Bronze Alloy Shackle,power Tools,ISO9001,UKASUS$ 2.3 - 45MOQ: 1 Piece

-

Mower ,Chainsaw Spark PlugsUS$ 0.05 - 0.5MOQ: 10000 Pieces

-

New Designs of Hand Saw Blade,cheaper Price Junior Hacksaw for WoodworkingNegotiableMOQ: 100 Pieces