Tungsten Carbide Flow Cage For Oil Field Industries

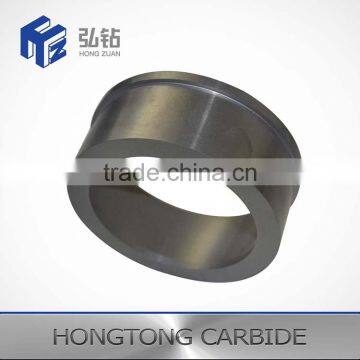

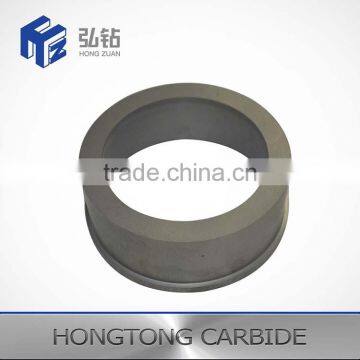

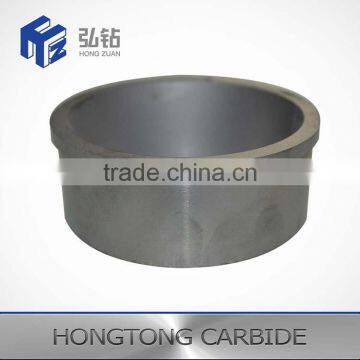

Pics of Tungsten Carbide Flow Cage For Oil Field Industries

Free smaple was available!

Tungsten Carbide Flow cage in a wide variety of configurations and specifications for use in wear corrosive and erosive conditions. We are manufacturing flow cage. We are manufacturing accurately designed with a diameter hole for easy transfer of gases and petroleum fluids. We are taking extra care for hole in diameter and we are pressing this cage by (Cold isostatic press) CIP machine.

Salient Features :

- High wear resistance grade

- Precise control on dimension

- Last longer due to its special properties to suit application

- Manufacture through cold isostatic pressing (CIP)

Applications :

- Controlling fluid handling and flow control devices

Grade No. and application for Tungsten Carbide Flow Cage For Oil Field Industries:

Grade No. | Density (g/cm³) | Hardness (HRA) | T·R·S (MPa) | Application Recommended |

| YG4C | 45.00 | 89.5 | 1800 | Mainly used as small buttons for percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG6 | 15.80 | 89.5 | 1700 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG8 | 14.70 | 88.5 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG8C | 14.70 | 88.0 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG9C | 14.50 | 87.0 | 2400 | Mainly used as the inserts and buttons for rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. |

| YG11C | 14.40 | 86.5 | 2450 | Chiefly for the inserts and buttons of heavy rock drill bits and rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. |

| YG13C | 14.30 | 86.0 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. |

| YG15 | 14.00 | 86.5 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. |

| YG16 | 14.10-14.30 | 87.5 | 2400 | It is mainly used for making cemented carbide substrate tips to be used in PDC cutters for excavating coal and oil field PDC bits. |

| YG20 | 13.40-13.70 | 85.0 | 2254 | Mainly for the stamping dies used in the conditions of heavy impact load and large strees |

All the produces must be inspected strictly with the ultrasonic and only those haven’t any harm such as pore can be shipped out.

COMPANY INFORMATION

ZhuZhou HongTong Tungsten Carbide Co., Ltd., located at Liyu Industrial Park, Zhuzhou National High-tech Development Zone, is a high-tech joint-equity enterprise integrating R&D, production and marketing of cemented carbide series products.

The company sets up an independent production and R&D base, covering a total area of 7,000m2 and a plant area of 4,000m2. There is a group of experienced technical personnel and a staff of 80 people including 5 engineers, 8 assistant engineers, and 29 people having college degree or above. The company mainly produces cemented carbide drawing dies, cold heading dies, mining tools, sealing rings, and other nonstandard products, wherein the cemented carbide drawing dies and cold heading dies take a leading position in the industry, and the bore of wire-drawing die can be minimized to 0.1mm, deeply popular with customers.

WORKSHP INFORMATION

PHYSICAL & CHEMICAL LAB

Q1 : Are you Factory or trading company ?

We are Factory with 15 years of production experience.

Q2: Where is your factory located ?

We are located in Liyu Industrial Park, Zhuzhou National High-tech Development Zone, is a high-tech joint-equity enterprise integrating R&D, production and marketing of cemented carbide series products.

Q3: Is the price Competitive?

We have our own Factory. Thanks to strong production and distribution system, we promise to offer our customers the most competitive price.

Q4: Are the products of high quality Tungsten Carbide Flow Cage For Oil Field Industries?

Yes. All products will be tested before bulk production, and we will check the physical properties, shape and tolerance for ensuring qualified products before shipping.

Q5: How to place an order for Tungsten Carbide Flow Cage For Oil Field Industries?

1. Fill your Order List in our online Inquiry System.

(Also you can directly contact our salesperson by E-mail / Skype / Whats App)

2. We will make a feedback to you ASAP after receive your order list.

Q6: What’s your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment.

For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Send Inquiry to This Supplier

You May Also Like

-

Angle Grinder Universal Woodworking Tools Starlock SawbladesNegotiableMOQ: 20 Pieces

-

Adjustable Countersink Drilling Bit SetUS$ 1 - 30MOQ: 3000 Sets

-

Tungsten Carbide Inserts to SpecificationUS$ 1 - 1.5MOQ: 100 Pieces

-

BladesUS$ 2 - 2.5MOQ: 5 Pieces

-

Masonry Router Bits For WoodUS$ 1 - 4.8MOQ: 100 Pieces

-

NozzleUS$ 12 - 50MOQ: 20 Pieces

-

Modelling Ball Tools Double Sided Bone Carving Tools 8 Different Sizes IncrementsUS$ 1 - 100MOQ: 100 Pieces

-

Item No.: STA4252 Cutter&BladeUS$ 1.5 - 1.55MOQ: 2000 Sets

-

Non Sparking Tools,U-type Bronze Alloy Shackle,power Tools,ISO9001,UKASUS$ 2.3 - 45MOQ: 1 Piece

-

Brush Cutter, Chainsaw Spark PlugsUS$ 0.05 - 0.5MOQ: 5000 Pieces