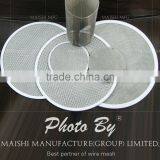

Stainless Steel Wire Disk Filter

Product information:

stainless steel wire disk filter

Material:stainless steel 201,202,301,304,316 etc.

Weave type: Plain weave, Twilled weave, Dutch weave

Features: Heat resisting,Corrosion resisting, Acid resisting

Uses: Mainly used for filtering and sieving, extensively used in petroleum, chemical industry, enviroment protection, mine, airspace, paper-making, electronic, metallurgy etc.

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves. In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under the warp threads that its neighbor went over, and vice versa.

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of a yarn that crosses over two or more yarns from the opposite direction.

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires.

1. Plain Weave: also called tabby weave, linen weav or taffeta weave, is the most basic type of weaves. In plain weave, the warp and weft are aligned so they form a simple criss-cross pattern. Each weft thread crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under the warp threads that its neighbor went over, and vice versa.

2. Twill Weave: In a twill weave, each weft or filling yarn floats across the warp yarns in a progression of interlaces to the right or left, forming a distinct diagonal line. This diagonal line is also known as a wale. A float is the portion of a yarn that crosses over two or more yarns from the opposite direction.

3. Plain Dutch Weave: similar with plain weave, just the weft and warp wire have different wire diameter and different mesh size.

4. Twill Dutch Weave: similar with twill weave, just the weft and warp wire have different wire diameter and different mesh size.

5. Reversed Dutch Weave: difference from standard Dutch weave lies in the thicker warp wires and less weft wires.

stainless steel wire disk filter application:

Application of the disk filter.

(1)Used in food and beverage industry(milk powder,tea,coffee and etc)

(2)Used in chemical and pharmaceutical industry(pharmaceutical products,plastic Recycling and Precision sieving of powders and etc.)

(3)Used in petrochemical industry.

(4)Used in water treatment system.

(5)used in aerospace industry.

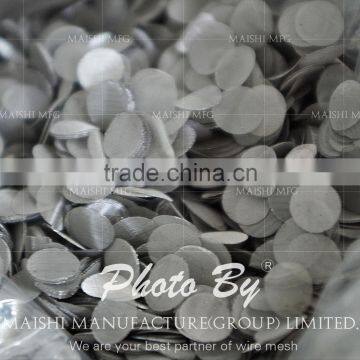

stainless steel wire disk filter shapes:

We can design various types of products according to our customers needs, for special designs please send your sample to us, the mould charge can be reduced in orders

Testing:

HEBEI MAISHI do strictly tested before the goods dispatched from our factory to ensure their quality. Make sure customers get perfect quality.

Introduction:

Hebei Maishi Stainless Steel Wire Mesh Manufacture Factory is one of the top manufacturers and exporters of stainless steel wire mesh. Our company was connected with production of metal wire mesh since 1986 and monofilament polyester screen printing mesh(bolting cloth) and nylon printing meh since 1995, in China. The machinery( Width 3900mm from Switzerland Sulzer and WJ1300/1600 A, B, D) and apparatus used in production process fully based on the high computer technology.

26 sets stainless steel high mesh count looms and 50 sets P7150 Sulzer looms.

Dedicated and experienced weavers.

Consistent quality products.

On-time delivery.

We have 15 R&D technical staffs,with more than 10 years experience.

80% repeat customers.

Reasonable claim refund system.

Payment:

100%T/T in advance if order amount less thanUSD10000.00, 30%paid in advance and 70%paid before shipment if order amount more than USD10000.00.

L/C payment is workable.

Any other payment term can be negotiatory

Send Inquiry to This Supplier

You May Also Like

-

Air FilterNegotiableMOQ: 1

-

High Quality Air Filter|OEM Air Filter|air Filter for EquipmentNegotiableMOQ: 5 Pieces

-

Zero Loss Automatic Electronic Solenoid Drain Valve for Big Capacity Compressor Air DryerNegotiableMOQ: 1

-

Aluminum Alloy High Efficiency Synthetic Fiber Element Air Compressor FilterUS$ 70 - 77MOQ: 10 Pieces

-

Truck Engine Intake Air Filter AF25271US$ 10 - 15MOQ: 10 Pieces

-

EAF1CB Compatible Refrigerator Air FilterUS$ 1.94 - 2.32MOQ: 5000 Pieces

-

Manufacturer High Quality Honeycomb Air Filter 208-9065 Air Filter Element SEV551H/4US$ 15 - 28MOQ: 10 Pieces

-

LFCN-400+ LFCN-400 Low Pass FilterUS$ 1 - 2MOQ: 10 Pieces

-

AF4553 1401654 Made In China High Profit Products Air Filter ManufacturerUS$ 3 - 29MOQ: 1 Piece

-

Air Filter Element for CD4 CDT4 329-23210US$ 1 - 10MOQ: 1000 Pieces