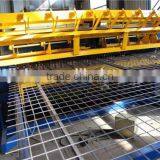

Automatic Fence Mesh Welding Machines for Processing 3D Fence Mesh Panel

Automatic Fence Mesh Welding Machines for Processing 3D Fence Mesh Panel

Parameter of Automatic Fence Mesh Welding Machines for Processing 3D Fence Mesh Panel

| wire diameter | 3-5mm |

| wire spacing | 50-200mm |

| max width | 2.5m |

| wire form | both line wire and cross wire are pre-straightened and precut |

| rated power | 125KVA*6 |

| rated votage | 380V 50HZ 3phase or as required |

| welding spot | 48pcs |

| welding speed | 45-75 cross wires/min |

Main features of Automatic Fence Mesh Welding Machines for Processing 3D Fence Mesh Panel

- automatic, both line wire and cross wire are pre-straightened and pre-cut.

- PLC control, HMI, touch screen and button input panel.

- easy to adjust wire spacing, different mesh size in one mesh panel.

- and servo motor cotrol the dawing mesh system and cross wire feeding system.

- the mesh could be panel fence mesh

Application of the 3D fence mesh:

railway fence, highway fence, bridge fence, airport fence, road fence, and so on.

main auxiliary machine for the Automatic Fence Mesh Welding Machines for Processing 3D Fence Mesh Panel :

- wire straightening anc cutting machine

- mesh bending machine for 3D fence

1.Wire Mesh Welding Machines JK-RM-2500B for reinforcing mesh or steel bar mesh

|  |

2. Wire Mesh Welding Machines JK-FM-2500S for fence mesh or construction mesh

|  |

3. Full Automatic Wire Mesh Welding Machine JK-AC-1200S for construction mesh or poultry cage mesh

|  |

4. electric welded mesh machines for construction mesh

|  |

All our machines could be customized, please contact us for much more details

We can customize the fence mesh welding machines, reinforcing mesh welding machine, animal cage mesh welding machine, wire mesh welding machine, welded wire mesh machine, chain link fence machine, hexagonal wire netting machine, gabion mesh machine, stone mesh machine, expanded metal mesh machine, barbed wire machine, razor barbed wire machine and so on, please do not hesitate to contact us.

Our company has a sound service system, from customer requirements gathering, pre-sales technical consulting, installation and commissioning in sales, and after sales maintenance of equipment. All of service system only for your satisfaction.

A: Pre-sale service; plant layout design, technical consulting, feasibility studies, cost and ROI analysis;

B: sales services: installation and commissioning, operator training, electrician and mechanic training;

1.Equipment installation and commissioning: assist and guide customer coordinate the equipment layout according to the actual situation, make reasonable arrangements for the overall planing of the installation location. Assigned technician to provide equipment installation, operation, ancillary facilities, production, repair, maintenance services and answer the relevant questions.

2.Training operation and maintenance personnel: our company will provide training of the operation and maintenance personnel according to customer’s requirement.

C: after-sale service; supply spare parts and provide after-sale services

1.supply of spare parts: keep records for each customer, provide long-term supply of spare parts, and send it to customers hand with the fastest speed according to customers’ requirement.

2.Unexpected emergency repair service: once the equipment have malfunction, and the user unable to rule out, we will arrange technician to the user factory in the soonest time, solve the trouble and resume production in time.

Tell us your need, we will surprise you with best price, best quality and best service!

Send Inquiry to This Supplier

You May Also Like

-

Electric Welded Mesh Wire Welding Equipment MachineUS$ 0.4 - 150000MOQ: 1 Set

-

Used Steel Wire Drawing Machine, Composite Wire Extractor MachineUS$ 2,000 - 6,000MOQ: 1 Set

-

(SS-AR45W)Amorphous Alloy Slim Ribbon of Amorphouse Magnet Core Produce MachineNegotiableMOQ: 1 Set

-

Stainless Steel Surface Polishing Machine Display Stand Surface Polishing Machine Kitchen Equipment Polishing MachineNegotiableMOQ: 1 Set

-

Full Automatic Stainless Steel Cattle Deer Grassland Fence Net Making Machine 7.5kW Motor Core Component for Fixed Knot FieldNegotiableMOQ: 1 Set

-

Welded Wire Mesh Machine In RollNegotiableMOQ: 1 Piece

-

Mechanical Hanging Wire Automatic Net Out and Net Down Mesh Welding Machine for Steel MeshCNY 76000 - 120000MOQ: 1 Set

-

Multi Wire Drawing Machine for 8 WiresUS$ 87464 - 97223MOQ: 1 Set

-

3d Wire Mesh Fence Machine 3d Metal Fence Panels Machine for SaleUS$ 5000 - 30000MOQ: 1 Set

-

10-25 Combined Drawing Machine-WeiguotechNegotiableMOQ: 1 Set