Forge grating welding machine factory from China

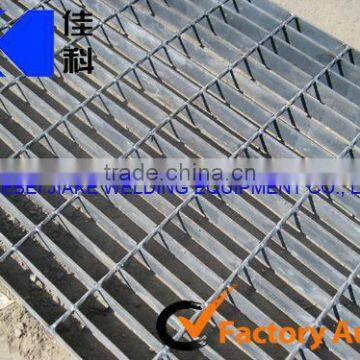

Steel doses of board weld production line to finish flat-rolled steel and round steel (is it entangle square steel to sprain ) horizontal to weld automatic production line of shaping alternately while being vertical, the products can reach hundreds of kinds of specifications , apply to the platforms of such trades as petroleum , chemical industry , electricity , quay , municipal administration , environmental protection , national defence ,etc. , hang and carry , enclose the bar , walk etc. extensively.

24 meters long, 3.8 meters wide production line this, divide into person , welder person , cut according to process worker of end head person , finished product deposit engineering location, worker of material loading,. Material loading adopt artificial material loading (flat-rolled steel ), horizontal pole (round steel ) hands over the material automatically , then weld automatically, walk into automatically, is it cut location , worker of material , cut end head automatically , artificial to operate with draw material car hand over the finished product to the depositing area of the finished product to reach, then one is put automatically , pile up the platform to drop automatically , is full of until piling up the platform, operate and introduce the car artificially and put out the finished product one.

Main technical data:

Input power | 3 phase 380V 50Hz |

Specified input power | 1600KVA |

Amount weld electric current | 200KA |

Most largely weld electric current | 350KA |

Flat bar steel width | 20-75mm |

Flat bar steel thickness | 2.5-7.0mm |

Horizontal pole(cross bar) diameter | 4,5,6,8mm |

Welding length | 6000mm |

Max. welding width | 1000mm |

Pitch of flat bar steel | 30mm, 40mm,50mm, 60mm (min. 25mm) |

Pitch of cross bar | 50mm, 100mm (from 38mm to 160mm) |

Welding speed | 15-25 times/minute (welding 2 cross bar each time) |

Send Inquiry to This Supplier

You May Also Like

-

1200W Fiber Laser Cutting for Sheet Metal Processing , Cutting Size 1500*3000 mmUS$ 150000 - 161000MOQ: 1 Set

-

Horizontal Conveyor Belt Joint Machine Platen , Auto Conveyor Belt Vulcanizing EquipmentNegotiableMOQ: 1 Set

-

5 Axis CNC Precision Machining Services For Marines , Vehicles , InstrumentsNegotiableMOQ: 1 Set

-

VW Belt Tensioner BearingNegotiableMOQ: 1 Set

-

Non-asbestos Rubber and PTFE Filled With Carbon Fiber Envelope GasketNegotiableMOQ: 1 Set

-

AC Spot Welding Machine 35KW Iron Sheet Spot Welding MachineCNY 25000 - 30000MOQ: 1 Piece

-

Corrosion Resistance Oil Steam Boiler Mud Drum ISO9001NegotiableMOQ: 1 Set

-

Heavy Duty Gantry Resistance Welding System Integration for Steel Bars MeshUS$ 15000 - 25000MOQ: 1 Set

-

Wire Heating Mesh Resistance Welding Machine Pneumatic Pressurized Spot Welding MachineUS$ 1500 - 6000MOQ: 1 Piece

-

Metal Roofing Sheet Roll Forming Machine, Roofing Sheet Making Machine With 20 Forming StationsNegotiableMOQ: 1 Set