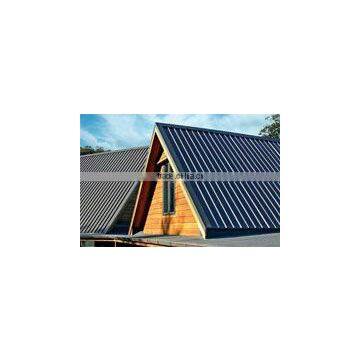

LMS Color Steel Roofing Roll Forming Machine , Wall Panel Cold Rolling Mill

LMS Color steel roofing roll forming machine , Wall panel cold rolling mill

Wall panel cold rolling mill

metal roofing roll forming machine

Color steel roofing roll forming machine

Main Specification:

Suitable Material G.I. Coil, PPGI Coil, G245

ii. Material Thickness 0.3 - 0.6 mm

iii. Material Width 1'220 mm

iv. Profile Width 1'000 mm

v. Profile Height 27 mm

vi. Profile Shape as drawing

II Production Process:

decoiling - manual shearing- roll-forming - hydraulic cutting - profile

III Main parameters:

i Decoiler 1 set

(1) Working Principle MANUAL

(2) Max. Decoiling Width 1'250 mm

(3) Max. Loading Capacity 6000 kgs

(4) Coil's Outer Diameter Ø 1,200 mm

(5) Coil's Inner Diameter Ø 508 ± 30 mm

viii Manual Roller Shearing 1 set

(1) Material Cr12 Steel

(2) Material Surface under Heat Treatment

(3) Function: PLC is calculating profile length within roll forming. Once

material is required to change, PLC is calculating the length for total

quantity and remind operator,

production finishes and able to manual shearing material before roll forming

so as to change material for new production. It is the advanced function for

roof machine and good for production to save material, no waste.

ix Main roll forming machine 1 set

(1) Roll Forming Stations 18 Nos.

(2) Roller's Material 40Cr

(3) Roller's Main Shaft Ø 75 mm, in 45# Carbon Steel,

Refined

(4) Machine Side-Wall Thickness 18 mm

(5) Main Bearing 6210

(6) Roll Forming Speed 8-12 meters / minute

(7) Main Motor 7.5 kw

(8) Power Transit by Gears & Chains

(9) Driven by Main Motor

(10)Speed Adjustment by Frequency Convertor

x Hydraulic Cut-Off Device 1 set

(1) Cutter Type Hydraulic Automatically Cut- Off Device

(2) Cutter Composition Motor, Hydraulic Pump

Stand,Electromagnetic Valve

(3) Cut-Off Mould 1 Set

(4) Cut-Off Mould Material Cr12, Heat Treatment

(5) Cut-Off Mould Material Surface Hardness HRC 60 - 62

(6) Cut-Off Working Pressure 10 MPa, Maximum

(7) Motor 3.0 kw

xi SIMPLE RUN OUT TABLE 1 set

(1) Length 6 meters

xii ELECTRONIC CONTROL SYSTEM

(1) Electronic Control System By PLC, Touchable

Screen,Frequency Convertor,

Encoder, etc.

(2) PLC Mitsubishi, Japan

(3) Touchable Screen Mitsubishi, Japan, 5.7"

(4) Electric elements Schneider, Japan

(5) Frequency Converter Mitsubishi, Japan, 5.5 kw

(6) Encoder Omron, Japan

(7) Power Supplier 380V, 50Hz, 3Phs

(8) Length Tolerance ≤ ± 2.0 mm

INSTALLATION, MAINTENANCE AND OPERATOR TRAINING

1. 1 year guarantee for spare parts is included in quotation.

2. The operator training in our factory is free.

3. The technician could be sent for installation and operator training at site, but the fee should be discussed separately.

Send Inquiry to This Supplier

You May Also Like

-

pu Rolling Shutter Door Cold Roll Formng MachineUS$ 15,000 - 30,000MOQ: 1 Set

-

Professional in Stock Roof Tile Roll Forming MachineUS$ 7,000 - 9,000MOQ: 1 Set

-

QT8-130T Concrete Roof Tile Machine PricesUS$ 16,503 - 605,501MOQ: 1 Set

-

2014 Newest Roof Building Materials Making MachinesUS$ 1,000 - 50,000MOQ: 1 Set

-

Steel / Hot Galvanized Temporary Suspended Platform , ZLP500 Maintenance CradleNegotiableMOQ: 1 Set

-

Cummins Inline 5 Data Link Adapter Heavy Duty Truck Diagnostic ScannerNegotiableMOQ: 1 Set

-

2013 / 07 Mercedes Benz Star Diagnostic Tool For Benz Compact 4NegotiableMOQ: 1 Set

-

High Speed Perfessional and Efficient DMR900 Ground Polishing MachineNegotiableMOQ: 1 Set

-

Metal Stamping MachineUS$ 1 - 10MOQ: 500 Kilograms

-

Roofing Tile Galvanized Steel Sheet Corruged Panel Making MachineUS$ 3,000 - 3,000MOQ: 1 Set