Specifications

1. Short lead time: 35 days for Seamless Pipe.2. Factory price

3. OEM welcomed

4. ISO 9001:2008

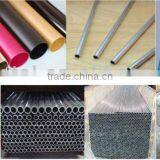

Product Name: Seamless Pipe

Payment and Shipping Terms:

Sample Lead time: 15-18working days include 7-10days making tooling if it's necessary.

Production lead time: 10-20working days.

Payment term:

1. Tooling: 100% prepaid by T/T

2. Parts: 30% upon order confirmation and balance before delivery by T/T.

3. Other payment terms can be discussed.

Shipping Term: FOB, CIF or others can be discussed.

Alloy, Chemical Composition and Mechanical Property of K&B Metal Aluminium

2000 Series

Alloy No. | Chemical Composition | Al Content ≥ | Temper | Tensile Strength ( Mpa) | Yield Strength (Mpa) | Elongation (%) | Hard (HB) | ||||||||||

Si | Mg | Fe | Cu | Mn | Cr | Ti | Zn | Others≤ | |||||||||

| Single | Total | |||||||||||||||

2011 | <0.40 | — | <0.70 | 5.0-6.0 | — | — | — | <0.03 | Pb:0.20-0.60 Bi:0.20-0.60 | 0.05 | 0.15 | Rest | T3 T8 | 380 405 | 295 310 | 15 12 | 95 100 |

2017 | 0.20-0.80 | 0.40-0.80 | <0.70 | 3.5-4.5 | 0.40-1.20 | <0.10 | <0.15 | <0.25 | Zn:0.15-0.20 | 0.05 | 0.15 | Rest | 0 T4 | 180 425 | 70 275 | 22 22 | 45 105 |

2024 | <0.50 | 1.20-1.80 | <0.50 | 3.8-4.9 | 0.30-0.90 | <0.10 | <0.15 | <0.25 | Ti+Zr<0.20 | 0.05 | 0.15 | Rest | 0 T3 T4 | 190 480 470 | 70 340 320 | 22-19 | 47 120 120 |

Drawn Seamless Pipe Advantages vs. Extruded Tube

1. Dimensional Tolerances-Because the tube is drawn over a mandrel and through a die, consistent dimensions can be achieved.

2. Superior Strength-Cold work increases tube strength and is stronger that an equivalent extruded tube.

3. Attractive Appearance-The drawing process enhances tube cosmetics by producing a bright finish with no weld lines.

4. Machining-The drawn tube’s superior strength and hardness characteristics enhance tube machinability. This assures a better machined surface with less gumming.

5. Bending-Better dimensional and temper characteristics greatly enhance tube bending operations. Consistent dimensions and temper reduce bender setup time and require less machine adjustments. Tube spring back is enhanced. Precise bends can be obtained.

6. Anodizing-The draw process refines the surface of the tube eliminating extrusion die lines and other surface irregularities. This provides a superior finish for bright dip and etches and clears anodizing.

Send Inquiry to This Supplier

You May Also Like

-

Aluminum Honed Tube Seamless 3003 6062 7072 Aluminium Round Pipe for Pneumatic Cylinder BarrelNegotiableMOQ: 1 Ton

-

Custom Truck CNC Auto Parts Heat Treatment Steel Machining OEM PartsNegotiableMOQ: 1 Ton

-

Glass Holders 40mmNegotiableMOQ: 1 Ton

-

Single-piece Hydraulic Quick Coupler / Hydraulic-grip Couplers for Connect Steel BarsNegotiableMOQ: 1 Ton

-

Super Strong Nickel Plated Magnets Diametrically Magnetized Magnets D20*4mmUS$ 0.01 - 2MOQ: 1 Ton

-

Elevator Door Lock / Locks , Lift / Elevator LockNegotiableMOQ: 1 Ton

-

Aluminum Precision CNC Milling Product (HSJ-145)OEM&ODM Competitive PriceNegotiableMOQ: 1 Ton

-

Aluminum Tube Coil/Aluminum Tube Aluminum Pancake CoilUS$ 0.1 - 10MOQ: 1000 Rolls

-

Large Diameter Aluminum TubeUS$ 1.2 - 5MOQ: 500 Kilograms

-

Brilliance High Performance Good Price Aluminum Extrusion FenceUS$ 2,200 - 3,500MOQ: 2 Tons