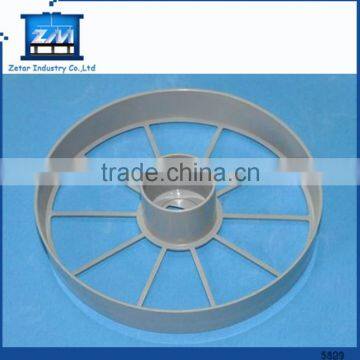

Professional Low Price Plastic Injection Moulding Company

Zetar Industry has shaped a reputation for excellence in Injection Moulding , Custom Insert Molding, Overmolding.

Advanced equipment, powerful technologies and manufacturing processes

Zetar has over twenty years of Injection Molding Expertise as Injection Moulding. With our knowledge we can provide outstanding service to fulfill all your molded part requirements. Our Facility and technical ability will exceed your expectations on service, quality and value.

We currently have a wide variety of Molding equipment ranging from 50 to 360 tons, including Horizontal& Vertical versions. In addition to our Molding Machines we have Temperature Controllers and Robotic Part Extractors which also help to save our cost for our customers.

· Core Capabilities of Injection Moulding Facility

· Prototype Design and Management · Precise plastic Injection Moulding

· Design / Manufacturing of Tools / Dies / Molds · Cost Effective Material Selection

· Program Management (APQP) · Design Input / Design Review

· Custom Plastic Insert Moulding · Custom plastic Injection Moulding

· Silicone rubber compression molding · Over moulding

· Surface Treatment: print, silk screen, paint · Vacuum Forming

· Assembly: ultrasonic welding · Finished Component Testing

· Quality Inspection ·Plastic Injection Moulding

Send Inquiry to This Supplier

You May Also Like

-

LG PC/ABS Lupoy GN-5001RF Polycarbonate + ABS Resin Plastic Raw MaterialUS$ 1.5 - 2MOQ: 25 Kilograms

-

High Quality Poe P Elastomer Raw Materials Poe Granules From ChinaNegotiableMOQ: 25 Kilograms

-

High Recovery Gold Washing Carpet Mining Alluvial Gold Moss Mat Grass Carpet Gold Mining CarpetNegotiableMOQ: 10 Rolls

-

Bottle Sealing Lock Buckle Plastic Rings for Decorative Sealing BOLIUS$ 0.1 - 0.2MOQ: 10 Pieces

-

Pier Buoy Floating Box on Water Pontoon BridgeUS$ 12 - 15MOQ: 50 Pieces

-

High-BARRIER Plastic Wear-Resistant and Chemically Resistant for Various Projects in POK M330A PolyketoneUS$ 3.72 - 3.88MOQ: 25 Kilograms

-

Flexible PVC Compounded Granules for Kids Sandal Slipper Production PVC Pellets for Shoes Making in Africa MarketUS$ 1060.00 - 1120.00MOQ: 5 Tons

-

16mm 19mm 25mm 38.1mm Round Square Tube End Leg Tip Plastic Pipe PlugNegotiableMOQ: 100 Pieces

-

Portable Pop up Privacy Shower Tent Spacious Changing Room for Camping Hiking Beach Toilet Shower BathroomUS$ 24.00MOQ: 1 Set

-

Shenzhen Runpeng Custom Injection ABS PP Plastic PartsNegotiableMOQ: 1