Home > Products > Paver block making machine > Low Price Semi Automatic QT40C-1 Cinder Paving Brick Moulding Machine

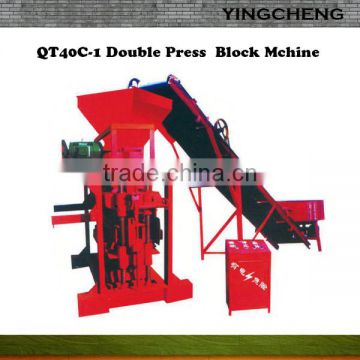

Low Price Semi Automatic QT40C-1 Cinder Paving Brick Moulding Machine

- qingdao

- T/T

You May Like

-

Low Price Semi Automatic QT40C-1 Semi Automatic Block Stacker Machine

-

Low Price Semi Automatic QT40C-1 Interlocking Paving Stone Machine

-

Low Price Semi Automatic QT40C-1 Hollow Blocks Big Factory for Sale From China

-

Cheap Hydraluic Blokc Machine QT4-18 Hollow Block And Solid Block Making Machine/cement Blocks Machines

-

Cheap Hydraluic Blokc Machine QT4-18 Full Automatic Block Making Machine for Sale

-

Cheap Hydraluic Blokc Machine QT4-18 Cement Block Machine Price/block Molding Machine/paver Brick Interlocking System

Product Details

| Condition | New | Type | Other, Hollow Block Making Machine, QT40C-1 cinder paving brick moulding machine | |

| Brick Raw Material | Concrete | Processing | Brick Production Line | |

| Method | Other, Electric vibration | Automatic | Yes | |

| Capacity | 4000 blocks/8 hours | Place of Origin | Shandong, China | |

| Brand Name | Fuda | Model Number | QT40C-1 | |

| Voltage | 220/240/380/440V | Power | 17.4KW | |

| Dimension(L*W*H) | 1350*1460*2300mm | Certification | CE/SGS/ISO9001 | |

| Warranty | 1 year | After-sales Service Provided | Engineers available to service machinery overseas |

Product Description

Low price QT40C-1 cinder paving brick moulding machine

Main Parameters of QT40C-1 cinder paving brick moulding machine.

| Type | QT40C-1 |

Control style | Electrical control system |

| Molding cycle | 40s |

| Pallet size | 850*450*40mm |

| Vibration frequency | 2800r/min |

| Vibration force | 33 KN |

| Host machine power | 11.15KW |

| Overall power | 17.4KW |

Voltage | 220/240/380/440V |

| Host dimension | 1350*1300*1650mm |

| Molding form | Vibration and Pressure |

| Main vibration form | Mould vibration |

Weight of host machine | About 2.5T |

Complete equipemnt of QT40C-1 cinder paving brick moulding machine.

Device | Specification | Power (KW) | Unit | Quantity |

Block machine | QT40-1 | 8.8 | Set | 1 |

Mixer | JD350 | 7.5 | Set | 1 |

Belt conveyer | L=6M | 1.1 | Set | 1 |

Mould |

|

| Set | 2 |

Block trolley |

|

| Set | 2 |

Spare parts and tools |

|

| Set | 1 |

Area and woker arrangement of QT40C-1 cinder paving brick moulding machine.

| Workshop | 50 m2 |

| Total area | 800 m2 |

Workers | operate:1 person |

| material loader:1 person | |

carry:1person | |

Total workers | 3 persons |

Theoretical workshop area is 50 m2 3-4workers are needed.The office,curing area and stacking area will be arranged according your conditions.

Productivity.

| Item | Size(mm) | Qty/mould | Cycle molding | Per day/8hours |

| Hollow block | 400*250*200 | 3 | 40s | 1800 pcs |

| 400*200*200 | 4 | 40s | 2500 pcs | |

| 400*150*200 | 5 | 40s | 3200pcs | |

| 400*100*200 | 7 | 40s | 4500pcs | |

| Brick | 240*115*52 | 18 | 40s | 12000pcs |

Material.

8-10% cement, 30-40% sand, 50-60% crushed stone ( you can add some other material by local situation).

Block.

1.Q: Can you make our zise of block?

A: Yes,We will design molds according to customers' drawing/picture of blocks.

2.Q: What is your payment term?

A: T/T,L/C or others.

3.Q: what is your delivery time?

A: Normally delivery time within 15-20 days since receive deposit.

4.Q: What is your MOQ( Minimum Order Quantity )?

A: 1set.

5.Q: How about your packing?

A: Suitable for shipping.

Inquiry service

Accept user’s enquiries by all kinds of ways and establish user’s product cognition.Provide all kinds of product data and let customer understand characteristics of product.

Pre-sale service

Accept inquiry of customers ,confirmation of investment advice of choice of product ,assist the customers to design the workshop.

In-sale service

Sale of product,help customers build the base ,technical training of customers’ workers ,practice of operation ,help to install ,train the operators in the workshop.

After-sale service

24 hours service of technology inquiry, instant components supply, regularly technical service guidance of maintain,long distance malfunction control.

Unique service

System up-grade,special design according to the customers’ requirement, mould renew ,supply new technology and products information.

Any question about concret brick making machine ,contact with us please,sincere service for you!

Contact Us

- Linyi Yingcheng International Trade Co., Ltd.

- Contact namelyying cheng Chat Now

- Phone0086-539-7166602

- AddressJinqueshan road No.1, Linyi, Shandong

Product Categories

| Automatic block making machine | Clay brick machine | Manual block making machine | Mixer |

| Moving block making machine | New Products | new type of building material | Paver block making machine |

New Products

-

Cheap Hydraluic Blokc Machine QT4-18 Interlock Brick Maker Machine Price/hydroform Brick Maker Machine

-

Cheap Hydraluic Blokc Machine QT4-18 Hydraulic Pressure Soil Block Making Machine

-

Cheap Hydraluic Blokc Machine QT4-18 Hydraulic Press for Paving Blocks Machine

-

Cheap Hydraluic Blokc Machine QT4-18 All Models Brick Making Machine

-

2015 Best Quality Hydraluic Blokc Machine QT4-18 South Africa -hydroform Brick Making Machine

-

Cheap Hydraluic Blokc Machine QT4-18 Interlocking Cinder Blocks Making Machine/automatic Interlocking Blocks Making Machine

-

2015 Best Quality Hydraluic Blokc Machine QT4-18 Interlocking Paver Brick Machine

-

2015 Best Quality Hydraluic Blokc Machine QT4-18 Economic Hollow Brick Production Line

-

2015 Best Quality Hydraluic Blokc Machine QT4-18 Price Concrete Block Making Machine/full Auto Block Making Machine

-

Hot Sale High Quality Qt1-10 Red Clay Brick Dimensions Clay Brick Factory

-

Hot Sale High Quality Qt1-10 Hand Operated Clay Brick Making Machine

-

New Type Qt1-10 Interlocking Clay Brick Machine/clay Brick Manufacturers

-

New Type Qt1-10 Clay Brick Moulding Machine/clay Brick Extruder

-

New Type Qt1-10 Red Clay Brick Floor Tile/clay Brick Making Machine for Sale

-

New Type Qt1-10 Used Clay Brick Extruder Machine/clay Brick Tunnel Kiln

-

New Type Qt1-10 Manual Clay Brick Making Machine/fire Clay Brick Kiln

-

New Type Qt1-10 Brick Machine Fired Clay Brick Making Machine

-

Qt1-10 Clay Brick Making Machine Price

-

Low Price Semi Automatic QT40C-1 Semi Automatic Block Making Machine Germany/automated Block Machine

-

Hot Sale High Quality Qt1-10 Clay Brick Making Machine Price Fire Clay Brick Kiln

-

Hot Sale High Quality Qt1-10 Clay Brick Making Machine Made in China Solid Clay Brick Machine

-

Hot Sale High Quality Qt1-10 Clay Brick Clay Brick Making Machine

-

Hot Sale High Quality Qt1-10 Full Automatic Clay Brick Production Line Clay Brick Plant

-

Hot Sale High Quality Qt1-10 Block Making Production Line Block Small Production Line Brick Machinery

Popular Searches

- sand making machine

- sand making production line

- building model making

- asphalt plant

- construction machinery

- asphalt mixing plant

- asphalt batching plant

- asphalt equipment

- bitumen mixer

- road machinery

- asphalt mixing equipment

- asphalt mixing station

- mixing plant

- concrete mixer

- asphalt concrete mixer

- mobile asphalt mixer

- asphalt bitumen mixer

- asphalt mixer plant

- vehicle equipment

- paver

- making machine

- asphalt paver

- engineering machine

- building machinery

- mini concrete paver

- bitumen sprayer

- asphalt drum plant bitumen

- double drum

- brick making machinery

- block machine

Recommended Products

- **Heavy-Duty Block Machine** – 1000+ Tons Pressure | For Large Factories & Contractors

- **Green Construction Equipment** – Recycled Material Brick Maker | Government Approved

- “Eco Brick Machine ” – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

- Beyond Automation: ZhanPeng Smart Brick Maker With Neural Network Optimization

- World’s First 'AI Brick Factory Brain' – Zhanpeng Self-Learning Brick Machine Adapts in Real Time!

- **Factory Price!** Automatic Block Making Machine – Includes Free Molds & Technical Support

- **Cheap Brick Machine** – Small Scale Production | Low Investment, Fast ROI | Perfect for Startups!

- **Smart Brick Maker** – PLC Control System | Energy-Saving | Ideal for Construction Business

- **Industrial Brick Machine** – Auto Feeding & Stacking | Cement/Concrete/Hollow Blocks Production

- **Fully Automatic Brick Making Machine** – Hydraulic Block Molder | 20,000 Bricks/Day | Eco-Friendly & Low Maintenance

- Green Construction Equipment – Recycled Material Brick Maker | Government Approved

- Eco Brick Machine – No Burning Needed | Uses Waste Materials (Fly Ash, Crushed Stone) | Zero Pollution

Find Similar Products By Category

- Manufacturing & Processing Machinery > Building Material Making Machinery > Brick Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

lyying cheng

Hi there! Welcome to my shop. Let me know if you have any questions.

lyying cheng

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile