DINTER edible oil refinery line

edible oil refinery line Introduction:

Generally a Crude Degummed Rapeseed Oil Machine including the flowing sections and auxiliary machine:

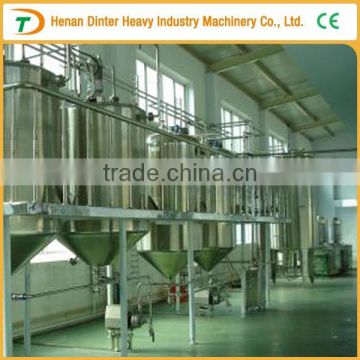

1. Degumming :Usded to neutrilizing ,and water washing,to rid off the acid .

2. Deodorization:Used to rid off the fetid smell/odour of oil by steam understand of high temperature.

3. Soap feet vessel:Used to refine the oil sediment from oil refiner,to get some oil from oil sediment .

4. Hot & Alkali water tank:Used to produce hot water heated by the steams ,also alkali water from the alkali dis-voling tank,for adding into the oil refiner.

5. Alkali dis-voling tank :Used to produce the alkali water .

6. Steam separator:Separating the steam to oil refiner,de-colorer,deodorizer,hot water tank,etc.

7. Decoloring vessel:Used to rid off the color of the oil

8. Clay tank:Store the medication decolored for the clay tank.

9. Transfer hot oil furance:Contact to the deodorizer part , producing high temperature (280 degrees orso) for deodorization.

10. Gear pump:Pump oil into kinds of vessel and tank.

12.Water pump:Pump cool water into water tank.

13. Transfer hot oil pump:Pump hot oil into transfer oil furance.

14. Cooling water tower:Cool water for cooling oil ,recycling using.

edible oil refinery line Main Advantages:

1.High oil yield:The oil yield of our product is higher 3-6% than old equipment,which can make considerable profits.

2.Energy saving:Energy eauals to lower production of electric power 40%,saving an average of 6 kilowatt-hourbasis,saving 36 RMB per day production of electricity.

3.High purity of oil:Vacuum filter residue, which ensure the pureness of the oil.

4. Small occupied area:The oil workshop can be used when the area of it is only 10-20 square meters.

edible oil refinery line can be packed in wooden case, several 40ft containers.

edible oil refinery line Services:

1. Turnkey Project Accepted;

2.Installation and Commissioning Guidance Supply;

3. 1 Year gurantee, long term technical support;

4.Training your local staff;

5.MSK long term cooperation shipping line;

10TPD sunflower oil refinery equipment Answer:

1.Price:

High quality with most reasonable price supply, more purchase orders, more favorable price!

2.. Quality Inspection:

Raw Material:Steel is purchased from Anyang Steel Factory(Famous brand);

Infrastrure: Rolling Machine, Cutting Machine, CNC, Auto welder, X-ray test, etc. When you come to visit factory, we can show you how 10TPD Cooking Oil Filtration Machine is produced.

3.Production Period:

10TPD sunflower oil refinery equipment needs 45 working days;

Send Inquiry to This Supplier

You May Also Like

-

PanQi Automatic Sunflower Sesame Olive Soybean Oil Press MachineUS$ 1300.00 - 1350.00MOQ: 1 Set

-

Factory Plant Flower Essential Oil Steam Distillation Equipment Distiller Herb Extraction Extractor Extracting MachineNegotiableMOQ: 1 Set

-

Cheap Mustard Oil Expeller Machine, Rotary Cold Oil Press Machine, Coconut Oil Expeller Machine Coconut CakeUS$ 4,000 - 4,600MOQ: 1 Set

-

Coconut Oil Extracting Machine, Coconut Oil Making MachineUS$ 3,000 - 5,000MOQ: 1 Set

-

Factory Supply Palm Kernel Oil Extraction MachineUS$ 2,000 - 2,500MOQ: 1 Piece

-

Best Seller Sunflower Linseed Oil Extraction Machine Price in Malaysia 0086 15803836485US$ 1,190 - 7,999MOQ: 1 Set

-

Factory Good Price Jatropha Oil Press Machine(mob:0086-15503713506)US$ 1 - 4,900MOQ: 1 Set

-

Best Selling Stainless Steel Small Cold Press Corn Oil MachineUS$ 1,100 - 4,400MOQ: 1 Set

-

Soybean Mini Oil Mill/mini oi PressUS$ 500 - 3,000MOQ: 1 Set

-

Cheap Oil Processing Machine for SaleUS$ 100 - 20,000MOQ: 1 Set