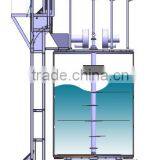

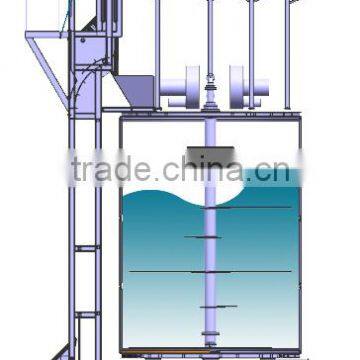

Goldenest Waste to Organic Fertilizer Fermentation Compost Equipment Animal Poultry Manure Processing Machine for Sale

Waste to organic fertilizer by fermentation recycling compost equipment animal poultry manure processing machine for sale

Features:

1, High-temperature aerobic fermentation, bio-bacteria technology using high-temperature, low energy consumption, low operating cost;

2, Equipment, small footprint, high degree of automation, a manipulation to complete the fermentation process;

3, Biological deodorization equipment to achieve through a gas discharge, no secondary pollution;

4, The device body made of stainless special materials to reduce corrosion and long life;

5, The main design of thermal insulation, auxiliary heating equipment to ensure the normal operation of a low temperature environment;

6, The treated sludge, kitchen waste, animal manure for organic fertilizer processing, utilization of resources.

Specification:

Specification / Model | GFJ-70 | GFJ-90 | GFJ-120 |

Fermentation reactor capacity | 70M3 | 90M3 | 120M3 |

Manure lifting hopper capacity | 0.7M3 | 0.7M3 | 1.2M3 |

Vortex force fan A | 5.5KW | 7.5KW | 7.5KW |

Vortex force fan B | 7.5KW | 11KW | 11KW *2 |

Hydraulic pressure station | 7.5KW | 11KW | 11KW |

The motor of manure lifting hopper | 2.2KW | 2.2KW | 2.2KW |

Filling Switch motor | 1.5KW | 1.5KW | 1.5KW |

Induced draft fan | 2.2KW | 3KW | 3KW |

Heating system (optional) | 3KW | 3KW | 5KW |

Gas treatment | High strength optical pyrolysis | ||

lubrication | Centralization lubrication | ||

Equipment total weight | 22 Ton | 28 Ton | 35 Ton |

Treatment efficiency(the manure’s moisture below 65%) | 7-8M3 | 10-11M3 | 12-13M3 |

High-temperature aerobic fermentation Process:

1. Organic waste( animal manure)

2. Input the lifting hopper

3. Fermentation in stainless steel reactor

4. Organic fertilizer

Exhaust gas manage technological Process:

1. 2 units water spraying tower

2. Electro optic cracking generator

3. Activated carbon adsorption tank

4. Induced draft fan

5. Clean gas chimney

Details:

In February 2014,Our company began importing and digesting foreign advanced technology, research and develop "livestock and poultry manure high-temperature aerobic fermentation reactor", also known as animal manure aerobic fermentation machine; Reactor material: 304 stainless steel, strong hydraulic driven, continuous fermentation oxygenation, a year four season run. By now, our company have produced three models of the fermentation reactor. Mainly for livestock and poultry farms, especially in the field of laying hens, every day to collect fresh manure and in situ to fermentation treatment.

Usually, the fermentation treatment plant need have two simple storehouses: one storehouse using for fresh manure storage, agitate and mix, the purpose is , decrease the unfermented manure’s moisture by adding dry material, to control the moisture below 65%; Another storehouse using for package and storage the fermented organic fertilizer.

The fermentation process generally not need to add fermentation additives(but in the cold season, could consider appropriate to add), Usually, just in a week,the reactor can produce of fermented thoroughly, completely decomposed, containing water in the 20% - 30%, organic fertilizer.

The reactor using multilayer insulation treatment, so can ensure in the reactor,the fermentation temperature is always maintained at 65-85 degrees Celsius, can effectively kill a variety of eggs and pathogenic bacteria.

Because of the fermentation process under a sealed condition, also could collect waste gas and odor to centralized processing, discharged clean gas into the atmosphere; achieve discharge standards, prevent secondary pollution, for the benefit of society.

The fermentation reactor can reduce the amount of capital investment, low energy consumption, small occupied area, high degree of automation, one person can operate several set fermentation equipment, the production cost is relatively low, investment income is relatively ideal.

feed auger Poultry feeding and nipple drinking system

Goldenest Machinery (Qingdao) Inc. is the professional enterprise which engaged in the design, research, and manufacture of the husbandry of poultry and livestock.

We have the most powerful R & D deparment and advanced equipment to manufacture our products. Exclusive auger production line imported from Germany have been used on Feb.2000.

Our products have been exported to more than 60 foreign countries, and also provide to many large scale farms in China. We have 25 engineers in designing and manufacturing auto feeding systems to poultry and pigs, as well as nipple drinking system, ventilation system, environment control system, and egg collecting system. All of them are designed by CAD / CAE / CAM systems with ISO9001: 2000 /CE certified .

Welcome to visit our company and contact us ,hope to get a good cooperation in future.

Mobile: +86 15864247432 (WhatsApp)

Send Inquiry to This Supplier

You May Also Like

-

2400 Model Self-Propelled Strip Pile Composter Crawler Organic Fertilizer Fermentation Equipment for SaleUS$ 9100 - 9100MOQ: 1 Piece

-

CE Certificated Hydraulic Press/Clothes/Bedclothes/Cotton/Woolen/Textile Baler MachineUS$ 4,500 - 100,000MOQ: 1 Set

-

Animal Manure Fertilizer Granulator/organic Fertilizer Pellet MachineUS$ 10,000 - 40,000MOQ: 1 Set

-

Organic Fertilizerfermentation MachineUS$ 6,000 - 15,000MOQ: 1 Set

-

Customized Inorganic Compound Fertilizer Production PlantUS$ 8900 - 21000MOQ: 1 Set

-

Factory Price Cow Dung Grinder Chicken Manure Fertilizer Grinding MachineNegotiableMOQ: 1

-

Wood Pellet Mill: High-Efficiency Solution for Sustainable Pellet ProductionNegotiableMOQ: 1 Unit

-

762 Rubber Track Chassis Case ModificationUS$ 2800 - 28000MOQ: 1 Pair

-

Customized Modification of Large Anti Sinking Half Chain Rail Harvester TractorUS$ 2800 - 28000MOQ: 1 Pair

-

Feed Additives Plant Extrcts of Cotton Seed Hull PriceUS$ 0.2 - 0.58MOQ: 1 Kilogram