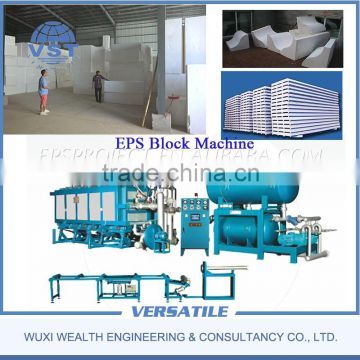

Vacuum Cooling Type Eps Foam Construction Blocks Machine

EPS block machine

1.Product Description

| Item | type | PSB-DZ200 | PSB-DZ300 | PSB-DZ400 | PSB-DZ600 |

| Mould cavity size | mm | 2040*1240*1030(mm) | 3060*1240*1030(mm) | 4080*1240*1030(mm) | 6100*1240*1030(mm) |

| Block size | mm | 2000*1200*1000(mm) | 3000*1200*1000(mm) | 4000*1200*1000(mm) | 6000*1200*1000(mm) |

| Steam | entry | DN80 | DN80 | DN150 | DN150 |

| consumption | 30-50kg/cycle | 50-70kg/cycle | 60-90kg/cycle | 100-130kg/cycle | |

| pressure | 0.8Mpa | 0.8Mpa | 0.8Mpa | 0.8Mpa | |

| Compressed Air | entry | DN40 | DN40 | DN40 | DN40 |

| consumption | 1.5-2 m3 /cycle | 1.8-2.2 m3 /cycle | 2-2.5 m3 /cycle | 2-3 m3 /cycle | |

| pressure | 0.6Mpa | 0.6Mpa | 0.6Mpa | 0.6Mpa | |

| Cooling water | entry | DN40 | DN40 | DN40 | DN40 |

| consumption | 0.2-0.4 m3 /cycle | 0.4-0.6 m3 /cycle | 0.6-0.8 m3 /cycle | 0.8-1 m3 /cycle | |

| pressure | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | 0.4-0.6Mpa | |

| Drainage | vacuum drain | Φ125mm | Φ125mm | Φ125mm | Φ125mm |

| steam vent | Φ100mm | Φ100mm | Φ200mm | Φ200mm | |

| condensate | Φ100mm | Φ100mm | Φ100mm | Φ100mm | |

| Blower outlet | Φ125mm | Φ125mm | Φ150mm | Φ150mm | |

| Throughput | 15kg/m3 | 5min/cycle | 6min/cycle | 7min/cycle | 8min/cycle |

| Power | kw | 20.5-24.5kw | 20.5-24.5kw | 24.5-35.5kw | 24.5-35.5kw |

| Overall dimension | L*W*H | 5700*4000*2850(mm) | 7200*4500*3000(mm) | 11000*4500*3000(mm) | 2600*3960*2906(mm) |

| Weight | kg | 6000kg | 7200kg | 12000kg | 15000kg |

| Room height required | mm | 6000mm | 6000mm | 6000mm | 6000mm |

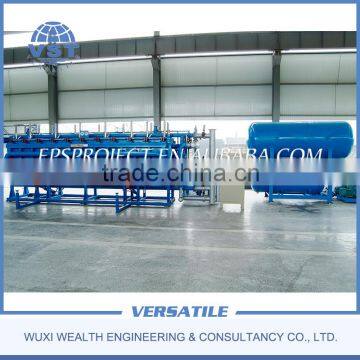

2. Product Pictures

3. Product Features

1)Strong Structure: Machine is made of high-strength square tubes and thick steel plates. Machine's all six panels are through heat treatment to release welding stress, so that panels cannot deform. under high temperature. After heat treatment, all panels are processed by sand blasting treatment t remove rust, then first painting and final painting is done to keep machine anti-corrosion. 2)Steam System: Use three ball valves to control steam, saving 20% steam comparing to traditional one main valve system. Steaming is controlled by Timer and three Germen electrical gauge switches, with a safty valve to save from gauge malfuncton situation. 3)Control System: Machine with PLC and touch screen for easy operation. |

4.Product Application

5.More Product

6.Packing & Shipping

Send Inquiry to This Supplier

You May Also Like

-

NEW Automatic Plastic Plate Making MachineUS$ 1,500 - 20,000MOQ: 1 Set

-

Top Performance XPS Foamed Board Making MachineUS$ 1,000 - 50,000MOQ: 1 Set

-

Factory Direct Soccer Wear Sports Game Service Organizations ServingNegotiableMOQ: 1 Set

-

Clear Moisture-proof Laminating Roll Film With Strong Bonding Strength For Credit CardsUS$ 4 - 5MOQ: 1 Set

-

Heat-resistant Customed OEM Non-toxic PVC Transparent Binding Cover For Stationery PackingNegotiableMOQ: 1 Set

-

High Quality Vacuum Forming MachineUS$ 2,899 - 18,999MOQ: 1 Set

-

Guangzhou High Point 30 Year Experience Cornice Moulding Eps Vacuum Forming Machine Best ServiceUS$ 3,130 - 13,350MOQ: 1 Set

-

2016 Hot Sale !pvc pp Vacuum Forming MachineUS$ 3,900 - 5,400MOQ: 1 Set

-

Fully Automatic Plastic Cup Thermoforming MachineUS$ 3,000 - 65,000MOQ: 1 Set

-

Automatic Foam EPS Plastic Cups Making MachineUS$ 9,000 - 290,000MOQ: 1 Set