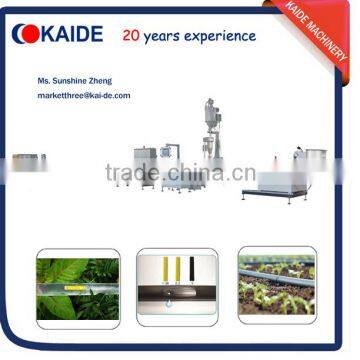

The drip irrigation pipe is widely used in water saving irrigation field, such as vegetables, flowers and trees. This production line can produce this kind of inline flat drip irrigation tape continuously with high speed, steady thickness distribution, high dripper inserting frequency and high precise hole punching.

Main Features of the Line:

1) Dripper feeding , choosing, conveying and inserting can be completed conscientiously and synchronously. The dripper inserting speed can be adjusted according to the prodution speed of the tape, ensuring accuracy and firm bonding of the dripper and tape.

2) SIEMENS PLC control system can achieve the synchronous control of the whole line and each parts, with high precision and easy to operate.

3) Specialy design the runner of the die head to make sure the steady extrusion of the pipe with thin thickness, which minimum thickness can be 0.15mm.

4) Optimized design of the vacuum calibrating tank to make sure the steady vacuum degree of the tank.

5) PLC monitoring punching sytem with visual sensor, to make sure the high speed punching with high precision.

6) Fully automatic pipe coiling machine to coil pipe and change roil at fixed length

Technical Data:

Send Inquiry to This Supplier

You May Also Like

-

Meltblown PP Non-Woven Fabric Making Machine for Face Mask N95 Medical MaskNegotiableMOQ: 1

-

PVC Monofilament Extruding Line(Used), Monofilament Machine, Monofilament EquipmentUS$ 8 - 10MOQ: 1 Piece

-

PVC Laminated Gypsum Board Production LineUS$ 100,000 - 200,000MOQ: 1 Set

-

With Iron Full Plastic Mask Nose Wire Making Machine for Face MaskUS$ 15,000 - 15,000MOQ: 1 Set

-

Factory Price Melt Blown Fabric Production Equipment and Extruder LineUS$ 120,000 - 130,000MOQ: 1 Set

-

Production Line Used for Granules Powder Material FeederUS$ 650 - 800MOQ: 1 Set

-

TZ Brand Plastic Filament Extruding MachineNegotiableMOQ: 1 Set

-

Air Bubble Roll Line Stage LightingUS$ 20,000 - 60,000MOQ: 1 Set

-

Food Grade Silicone ProductsNegotiableMOQ: 1 Piece

-

Semi-auto Finger Joint Shaper(hydraulic)NegotiableMOQ: 1 Piece