Working principle

1, molding parts:

By putting film plate, transfer jig, molding, finishing bottom, line cutting and subsection cutting knife, complete film material shell making.

1. 1 Molding:

Put film packaging material from the plate after guide wheel, transmission jig into the forming station, the station has a preheating, heating and forming mold, in addition, the slot is equipped with corresponding docking with mould (blow molding) for the use of production.

Film working:

Smooth preheating mold is located in the first clamping.

Heated mold is located in the second clamp.

Forming dies in the third clamp.

Docking vertical mold and molding mold.

1. 2 finishing bottom and dotted line cutting.

Membrane material forming station, finishing bottom edge by cutting knife, line cutting, making it a unified at the bottom of the form and is divided into single grain.

Equipment advantages

Detection function: 1. The PLC of run through PLC on-line monitoring function can breakdown self check alarm and show the cause of the problem simultaneously convenient operator timely troubleshooting.

2. The operation mode, the machine running in the following way: reset, automatic, manual, emptying.

2.1 reset

All parts of the machine after in the initial position, have to start the machine conditions; In manual operation or the manual way of molding machines need to be reset after operating

Ø check machine connection is correct, open the main switch

Ø manual switch in "off"

Ø press the reset button

2.2 automatically

Machine with PLC controller control the operation of the order

Ø check machine connection is correct, open the main switch

Ø install roller

Ø press the reset button

Ø press the start button

2.3 manual: on a touch screen, click on the "manual" to enter submenu, click on a single function to run

3. The thermostat setting

On the control panel is equipped with the thermostat, each a thermostat control temperature alarm peak (set) according to production needs, if exceed its value, the temperature on the display alarm lights, machine stop.

Technical Parameters:

Output | 8000—25,000pcs/hour |

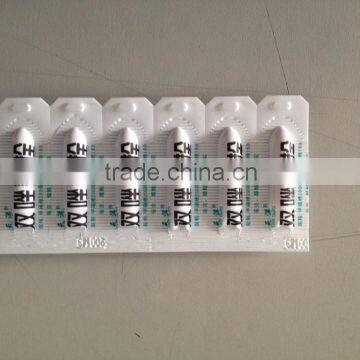

Single dosage | 0.5—5ml |

Dosage allowed | <±2% |

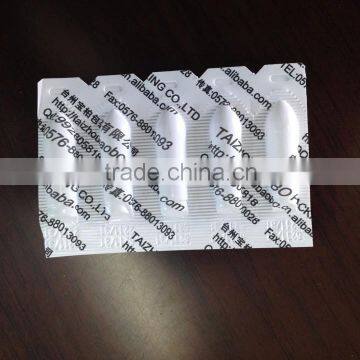

Forming Shape | bullet shape, torpedoes, duck bill and other various shapes |

Adapt to the host | synthetic fat glyceric acid glycerides, glycerin, gelatin and polyethylene glycol, polyethylene |

Atmospheric pressure | 0.6Mpa |

Consume the tolerance | 1.5m3 |

Water quantity | 50kg/h (recycling) |

The voltage of the power | Three-phase 380V |

Total power | 3KW |

External dimension | 2750*1250*1380mm |

Total weight | 500kg |

Send Inquiry to This Supplier

You May Also Like

-

GZP Automatic High-speed Rotary Tablet Press MachineNegotiableMOQ: 1 Set

-

JINHE Double Conical Pharmacy and Medical Dry MixerUS$ 2,000 - 15,000MOQ: 1 Set

-

Small Electronics Pill Capsule CounterUS$ 1,000 - 3,000MOQ: 1 Set

-

Popular Selling and Best Quality Pill Counting MachineUS$ 1 - 2,600MOQ: 1 Set

-

100PCS / TIME Smaller Tablet Counter Manual Tablet Capsule CounterUS$ 830 - 925MOQ: 1 Set

-

Rotary Vibrating Screen Sieving Machine for Small Gears, SprocketsUS$ 400 - 10,000MOQ: 1 Set

-

Industrial MixerUS$ 1,300 - 1,800MOQ: 1 Piece

-

Ginseng Cutting MachineUS$ 890 - 890MOQ: 1 Set

-

MAT TABLET MACHINENegotiableMOQ: 1

-

High Quality Stainless Steel Microwave Extracting Machine With Factory PriceUS$ 2,900 - 50,000MOQ: 1 Set