Low Price Portable Ultra-high Frequency Electromagnetic Brazing Machine Induction Heating Machine (JLCG-3)

Low Price Portable Ultra-high Frequency Electromagnetic Brazing Machine Induction Heating Machine (JLCG-3)

Low Price Portable Ultra-high Frequency Electromagnetic Brazing Machine Induction Heating Machine (JLCG-3)

Main Feature

- 1. Ultrahigh series: high frequency, able to heat Φ 0.1mm work-piece.

- 2. Small size, light weight, low failure rate and conservation of energy. (which can save the power by 70% as compared with glass-ceramic vacuum tube high frequency heating machine)

- 3. It can ensure the solid welding point which is pleasing and delicate in appearance, integral geometric configuration, perfect surface grain, complete crystal structure of internal metal part, limited annealing range and elimination of obvious weld knot.

- 4. About ten types fault protection and display of over-current, over-voltage, water shortage and phase missing can provide higher reliability and durability.

- 5. It is applied to the welding of coupler and inserts used in metal glass manufacturing as well as electric appliance and electronics industries, non-contact welding of internal parts of small-size relays, high-pressure refrigerating parts, headwear decorations, metal ornamental articles an art wares.

Low Price Portable Ultra-high Frequency Electromagnetic Brazing Machine Induction Heating Machine (JLCG-3)

Technical Parameters

Model | JLCG-3KW |

Input power desire | Single phase 220V 50-60HZ |

Max input current | 14A |

Max oscillate power | 3KW |

Oscillate frequency | 0.5-1.1MHZ |

Cooling water desire | >0.2MPa 2-6L/Min |

Duty cycle | 100% 40℃ |

Net Weight | 15KG |

Dimensions | Generator: 260X270X145mm |

Transformer: 120x60x105mm | |

Cable length | 2-6 ( Meters ) |

Low Price Portable Ultra-high Frequency Electromagnetic Brazing Machine Induction Heating Machine (JLCG-3)

Heating Principle:

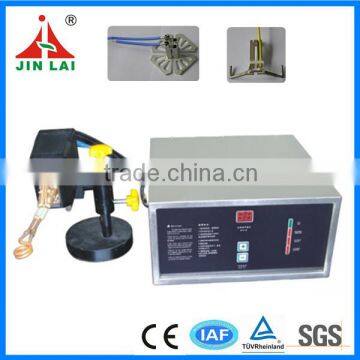

JLCG-3KW Generator Outside :

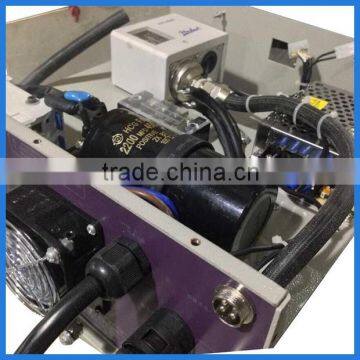

JLCG-3KW Generator Inside :

JLCG-3KW Face-plate :

Main Parts Introduction

- 1. Germany SIEMENS INFINEON IGBT Module. ( 40-60KHZ oscillation frequency, fast response time, superhigh stability, almost spatter-free welding )

- 2. Japan Nichicon electrolytic capacitor. ( filter capacitor )

- 3. Imported transistor integrated block.

- 4. All water pipe use thermostability, High pressure resistance best quality material.

- 5. Main card, signal circuit, drive circuit board,control circuit board and components are adopted:Toshiba, Hitachi,Motorola, China's top manufacturers.

- 6. International advanced all-solid-state semiconductor power devices.

- 7.Technical advantage:perfect control, alarm display circuit, getting full automatic tracking frequency, continuous adjustable power, safe dependable protection,clear and accuracy data display and etc.

- 8. Superiority Advantages: fast heating, wide application, small size, easy installation, simple operation, low power consumption, high efficiency.

JLCG-3K Applications :

- 1. Brazing materials: copper and brass brazing, tungsten steel and stainless steel brazing, iron and copper brazing, aluminum and copper brazing and other metal brazing.

- 2. Glasses welding, fishing tool welding, hardware appliances welding.

- 3. Carbide saw and saw-tooth welding, carbide blade welding.

- 4. Jewelry, watches welding.

- 5. Electronic industry: motor rotor hot-cooperate, electrode silver soldering and tin soldering.

- 6. Metal implants, bulbs fight electrode.

- 7. Band accessory soldering, golf head, pipe welding.

- 8. Communication equipment soldering, copper coaxial cable connector soldering etc.

Packing List

Item | Name of machine or parts | Specification | Amount |

1 | JLCG-3KW Generator | - | 1 pcs |

2 | JLCG-3KW Transformer | - | 1 pcs |

3 | Foot pedal | 3 core | 1 pcs |

4 | Induction Coils | - | 2 sets |

5 | Instruction Manual | - | 1 pcs |

6 | Product catalog | - | 2 sets |

Company Profile:

Dongguan Jinlai Electromechanical Device Co.,ltd. founded in 1996,

which is engaged in R&D, production and sale of solid Induction heating machine

professionally.Several senior experts of induction heating equipment gathered

here, who initiate the induction heating machines with environmental protection

and highly effective energy conservation, positively and diligently.

Pre-sale service:

- 1. recommend the most suitable machine for customers, according to their requirements.

- 2. Inquiry and consulting support.

- 3. Sample testing support.

- 4. View our Factory.

In-sale service:

- 1. Strictly manufacture the machine, according to relevant technical standards.

- 2. Take run test, according to relevant equipment test run regulations.

- 3. Strictly check up the machine, before delivery

- 4. Delivery on time.

After-sale service:

- 1. 12 months warranty period

- 2. Within one year free warranty, any fault caused by non-artificial reason, any quality problems such as design, manufacture, or procedure occurs, Jinlai shall provide replacement parts after detecting the faults.

- 3. If any big quality problems occurs out of the guarantee period, Jinlai will send maintenance

- 4. technician to provide visiting service after checking with the customer and charge for a favorable price.

- 5. Jinlai will provide a lifetime favorable price to the buyer with the materials and spare parts used in system operation, equipment maintenance.

- 6. The above mentioned are only basic after-sale service requirements, we will make more promises related to quality assurance and operation guarantee mechanism.

Ultrahigh Frequency Series JLCG (100KHZ-1.1MHZ)

If you would like to see more products of our company, please click on the following picture and then contact us.

Send Inquiry to This Supplier

You May Also Like

-

Multifunctional Hydraulic Baler/hydraulic Briquetting Machine Manufacturing PlantUS$ 5500MOQ: 1 Unit

-

Automatic/manual Fluidized Bed Dip Powder Coating Equipment Line for Refrigerator Shelves ProductionUS$ 2000 - 40000MOQ: 1 Set

-

Replaceable Knives Wood Chipper Moveable Type Chips Ready for Compost or BoilersNegotiableMOQ: 1 Set

-

Hydraulic Baler for CansUS$ 3000MOQ: 1 Unit

-

Automatic Fluidized Bed Dip Powder Coating Equipment LineUS$ 2000 - 40000MOQ: 1 Set

-

Wood Chipper Price Tree Branches Reduce Debris by 80% With Precision BladesNegotiableMOQ: 1 Set

-

Drum Wood Chipper Manufacturer Quality Ideal for Forestry, FarmsNegotiableMOQ: 1 Set

-

Drum Wood Chipper Price Quality Low Noise, High PowerNegotiableMOQ: 1 Set

-

Drum Wood Shredder Manufacturer Auto Eco-Friendly Green EnergyNegotiableMOQ: 1 Set

-

Wood Crusher Price Quality Municipal Waste ManagementNegotiableMOQ: 1 Set