Home > Products > Injection mould > precision connector mold/mould part

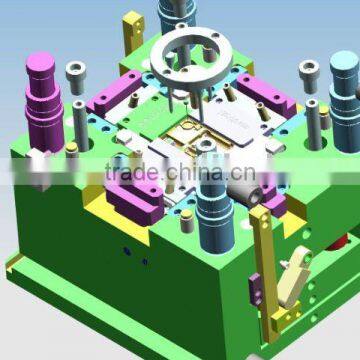

precision connector mold/mould part

- 50 Set / Sets per Month

- shanghai

- T/T Credit Card PayPal

You May Like

-

Plastic Injection Mould with top quality

-

Custom Injection Mould/Home Appliance Injection Mould

-

Professional plastic injection products factory

-

Injection plastic parts and mould for appliance

-

Plastic Parts Of Home Appliance/Plastic molds for home appliance

-

Injection plastic household mold ! Best price for you with high quality!

Product Details

| Place of Origin | China | Brand Name | RUNFENG | |

| Model Number | injection mould | Shaping Mode | Plastic Injection Mould | |

| Product Material | Plastic | Product | Household Product |

Product Description

Specifications

Plastic Dustbin1)economy and durability

2)strict quality inspections

3)OEM service available

Plastic Dustbin

1)economy and durability

2)strict quality inspections

3)OEM service available

Injection molding are batch production certain shapes complex components used by a kind of processing methods. Specific means that a heated melting material by high-pressure scored by cavity, cooling after curing, get forming products.

The injection molding process can be roughly divided into the following six stages of "shut the mould - injection - pressure-keeping - cool down - open mold - products take", the above process can be repeated, continuously produce products.

Injection molding machine injection molding machine can be divided into fits the mould device with an injection device. Shut the mould device main function is to realize mould opening and closing and ejection products. Shut the mould device can be divided into the long rod and using directly hydraulic executes shut the mould of direct pressure type.

Injection device is make resin material heated melts into the mould device. The resin boffins nitrogen-treated barrel, through screw rotation will melt transfer to the front end of the barrel. In the process, in heater under the effect of heating makes barrel within the resin material heated, in the screw of shear stress under the role that resin, will become molten state equivalent of molding product and mainstream way, way of molten resin shunt occluded in barrel front-end (called measurement), screw forward will materials into the cavity. When molten resin in the mould flow, must control screw movement speed (injection velocity), and in full of the cavity with resin pressure (pressure) the control. When screw position, injection pressure reaches a certain value when we can transmit speed control switch becomes pressure control.

Mould means, colophony material into metal model with certain shape after we get the products of the device. In fact in order to control the mould temperature, in the mold and make cold media (warm or oil) through the cooling hole, heater devices.

Contact Us

- Suzhou Runfeng Mould Technology Co., Ltd.

- Contact nameChunrong Yuan Chat Now

- Phone86-0512-67220309

- AddressNo.416,Chunfeng Road, Huangdai Town,Xiangcheng District,Suzhou City,Jiangsu Province,China, Suzhou, Jiangsu

Product Categories

New Products

-

Hot selling Plastic injection mold manufacturer

-

kitchen hood parts ! OEM product welcome !

-

Customized Motor Test Systems -Testing Steam Turbine Engines

-

high quality with competitive price for metal injection Mold for Household Electrical

-

Metal centrifugal wind wheel

-

Injection molding for metal centrifugal wind wheel

-

Metal centrifugal wind wheel/Fan impeller for Air Conditioning

-

High quality for Metal centrifugal wind wheel motor with competitive price

-

household appliance range hood

-

Kitchen range hood, ventilation hood, cooker hood , good price !

-

Kitchen Ventilation System

-

multi-function range hood/home appliance with competitive price

Popular Searches

- plastic mould

- Pc Abs

- Pp Pvc Hdpe Abs

- 3d design

- document

- Agricultural Plastic Products

- plastic injection

- injection moulding

- injection mold

- Plastic Injection Part

- injection mould

- extrusion die

- computer plastic mould

- home automation

- Plastic Injection Mould

- Mould Design

- rubber mold

- Automotive Plastic Products

- Molded Product

- Plastic Injection Molding Product

- Injection Moulding Product

- Moulded Product

- Injection Mould Bumper

- Injection Molding

- Household Products Part

- cycle component

- Mould Maker

- rubber flap

- bumper mold

- Car Fenders

Recommended Products

- Professional Manufacturer Mould Makers Good Price Grille Mould

- Good Design Plastic Injection Molding Plastic Auto Mirror Mould

- Good Design Plastic Injection Molding Custom Made Plastic Auto Mirror Mould

- Best Selling Product Plastic Injection Moulding Plastic Auto Door Mould

- China Leading Plastic Injection Molding Mold Manufacturer Plastic Auto Dashboard Mold

- APG casting moulds epoxy resin transformer insulator outdoor HUAAO company

- epoxy resin camping mould customized with APG machine for transformer insulator

- epoxy casting mould APG clamping mould for electric transformer insulator

- APG epoxy resin casting mould

- epoxy resin transformer mould with APG machine for epoxy resin PT/CT insulator bushing spout

- resin cast mould customized with APG mould for PT/CT insulator

- epoxy resin casting mould customized with APG machine for pt/ct insulator

Find Similar Products By Category

- Manufacturing & Processing Machinery > Mould > Plastic Mould

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Chunrong Yuan

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Chunrong Yuan

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile