Automatic Extrusion Textured Soya Protein Making Machine

I. Description

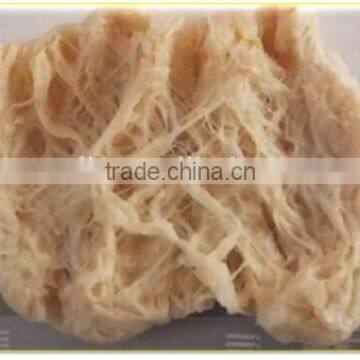

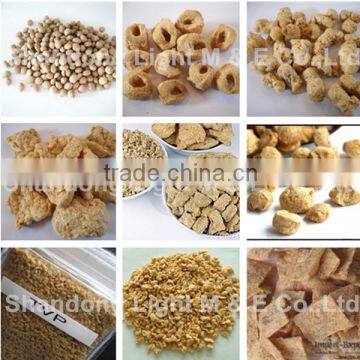

Automatic Extrusion Textured Soya Protein Making Machine is developed and manufactured on the basis of our experience combining with the advanced machines from foreign countries. This line takes soybean meal and peanut meal as main raw materials. After milling, mixing, extruding and cutting, the meal becomes layer fiber structure. With high nutrition, the finished products look and taste like meat, absorb oil and water easily, no cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deepfreeze food production and all kinds of vegetarian snacks and food.

1. Raw Materials: Soybean Meal, Peanut Meal etc.

2. Products: Soya Nugget with Different Shapes

3. Capacity: 120-150 KG/H, 200-200KG/H, 500-800KG/H

4. Flow Chart: Fried Type: Mixing —Extrusion —Air Conveying —Baking

5. Voltage: 380V/50HZ/Three Phase, 220V/50HZ/Single Phase or Change As Rquired

6. Machines Materials: All the machines are made by food grade stainless steel.

7. Technical Parameters

Model | Installed Power | Power Consumption | Output | Size(L×W× H) |

LT65P | 100kw | 70kw | 120-150kg/h | 13000x1300x2300mm |

DL75 | 183kw | 128kw | 200-300kg/h | 14500x1300x2400mm |

A85 | 243kw | 170kw | 500-800kg/h | 17000x2400x4300mm |

II. Sample Picture

III. Flow Chart

IV. Details & Features

1. The screw is made of alloy (38CrMoAL) by nitriding process, high strength and wear-resting. And it has good self-cleaning ability and does not need to discharge or clean the barrel and screw, when roasting or replacing of materials.

2. It adopts speed-adjusted converter on feeding system, extrusion system and cutting system. Food grade stainless steel twin screw feeding machine guarantees stable materials feeding in the whole food process.

3. The gearbox has automatic lubrication function, with extends gear life.

4. Radiator is increased on driving part for forced cooling effect, and it ensures extruder operate safely.

5. Barrel with water-cooled circulation, raw materials not only for corn/rice, also for wheat flour/starch with high viscosity. Different moisture-extrusion temperature ratio, whole-expanded and half expanded as different type of products.

6. Cutting knife fixed in the die head seat, rotary cutting by V-belt drive.

V. Packaging

VI. Service & Turnkey Solution

1.) Consultation service before, during,and after sales;

2.) Project planning and design service;

3.) Debugging of equipment until everything is functional;

4.) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

5.) Training of equipment maintenance and operating personally;

6.) New production techniques and formulas;

7.) Provide 1 year complete warranty and life-time maintenance service.

VII. Company Information

1. Company Image

2. Participating Exhibition

3. Visitors

4. Glories of Company

5. Cooperative Clients

6. World Market

VIII. Please Feel Free to Contact Us

IX. Our Most Popular Snacks Food Production Line

No. | Production Line |

1 | Extruded Kurkure / Nik Nak Snacks Food Production Line |

2 | Core Filling / Inflating Snacks Production Line |

3 | Breakfast Cereals / Corn Flakes Production Line |

4 | Extruded Doritos / Tortilla Corn Chips Snacks Food Production Line |

5 | Crispy Chips / Sala / Bugles Production Line |

6 | Nutrition Powder / Baby Rice Powder Production Line |

7 | Nutrition Rice / Artificial Rice Production Line |

8 | Bread Crumbs Production Line |

9 | Extruded Soya Meat Food Production Line |

10 | Extruded Pet / Dog / Cat Food Production Line |

11 | Chewing / Jam Center Pet Food Production Line |

12 | Extruded Snacks Pellet Food Production Line |

13 | Instant Noodles ProductionLine |

14 | Fried Wheat Flour Snacks Production Line |

Send Inquiry to This Supplier

You May Also Like

-

Hot Good Quality High Efficient Automatic Soy Nuggets MachineryUS$ 9,000 - 30,000MOQ: 1 Set

-

Good Quality Automatic Isolated Soy Protein Making MachineryUS$ 9,000 - 30,000MOQ: 1 Set

-

Fully Automatic Industrial Stainless Steel Soya Bean ExtruderUS$ 9,000 - 30,000MOQ: 1 Set

-

Automatic Industrial High Protein Content Full Fat Soya ExtruderUS$ 9,000 - 30,000MOQ: 1 Set

-

Fully Automatic Stainless Steel Extruded Soy Chunks MachineryUS$ 9,000 - 30,000MOQ: 1 Set

-

Factory Supply Automatic Vegetarian Soya Meat Processing LineUS$ 20,000 - 50,000MOQ: 1 Set

-

Innovative Easy To Operate China Soya Meat Processing MachineUS$ 20,000 - 50,000MOQ: 1 Set

-

Best Price China Industrial Automatic Soya Meat Making MachineUS$ 20,000 - 50,000MOQ: 1 Set

-

Factory Supply Automatic Vegetarian Soya Meat Production LineUS$ 20,000 - 50,000MOQ: 1 Set

-

Industries Hot Sale Automatic Extruded Textured Soy Protein Production LineUS$ 20,000 - 50,000MOQ: 1 Set