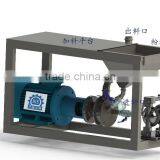

PHM Liquid & Powder Mixer/Solid-liquid Mixing Machine/Solid-liquid Mixer

Flashmix Powder/Liquid Mixers for viscous products are used to incorporate solid ingredients into liquid products circulated by a centrifugal and a lobe rotor pump. The range of applications include applications like incorporation of solid ingredients into viscous sauces and incorporation of pectins into glucose in jam production. An in-line mixer can be installed right after the centrifugal pump to break up lumps

Operating principle

The table blender is a compact unit. It consists of a centrifugal pump with a venturi system at the suction side and a hopper with a butterfly valve at the upper part to add solid product to the pumped liquid. Optionally, a mixer can be installed right after the centrifugal pump. And a lobe rotor pump is installed after the mixer.

The ventury system and the suction of the pump create depression at the base of the hopper. When the valve of the hopper opens, the solid ingredient is drawn from the hopper and is totally dissolved when it passes through the casing of the pump.

When the product starts getting thicker, it is the lobe rotor pump that maintains the flow of the liquid, thus maintaining a high level of the solid ingredient absorption capacity.

To achieve the best possible dissolution, it is recommended to recirculate the product (batch production) till all the solid/powder product is suctioned and then, when the solid product is completely incorporated into the liquid product, continue recirculating the product for a while.In some cases, the table blender can be used in-line depending on the solid product to add and the required level of dissolution.

Food industry: milk, beer, chocolate, syrup etc.

Daily use chemicals: cosmetics, fragrance, toothpaste, detergent, shampoo, shoe polish, soap, face cream etc.

Pharmaceutical industry: emulsifier, syrup, nutrition, medicine, Paste the pharmaceutical, bio-products etc.

Chemical industry: paints, dyes, paints, oil agent, emulsified asphalt, adhesives, leather goods etc.

| Model | Power(Kw) | RotorSpeed (rpm) | Flux(M3/h) | Diameter for Inlet(mm) | Diameter for outlet(mm)) |

| PHM-O-60 | 1.5 | 2900 | 0-1.5 | 25 | 20 |

| PHM-O-100 | 2.2 | 2900 | 0-3 | 40 | 32 |

| PHM-O-125 | 5.5 | 2900 | 0-5 | 50 | 40 |

| PHM-O-150 | 7.5 | 2900 | 0-10 | 50 | 40 |

| PHM-O-180 | 15 | 2900 | 0-18 | 65 | 50 |

| PHM-O-200 | 22 | 2900 | 0-25 | 65 | 50 |

| PHM-O-220 | 37 | 2900 | 0-35 | 80 | 65 |

| PHM-O-100 | 7.5 | 2900 | 0-8 | 50 | 40 |

| PHM-O-125 | 11 | 2900 | 0-10 | 50 | 40 |

| PHM-O-150 | 18.5 | 2900 | 0-20 | 65 | 50 |

| PHM-O-180 | 30 | 2900 | 0-25 | 65 | 50 |

| PHM-O-200 | 37 | 2900 | 0-30 | 80 | 65 |

| PHM-O-220 | 55 | 2900 | 0-40 | 125 | 100 |

The flow range in the table means the data when the media is water.

Adjusting speed adopts variable speed or variable speed inverter. It can work together with cooling or heating device.

Interface way can choose (hoop, thread, and flange).

Material of the pump body can choose SS 304, SS 316, and SS316L.

Sealing material: Standard rubber ring is silicone rubber, according to the media requests; you can choose fluorine rubber, EPDM, PTFE.

Why Choose us:

Good Technical research and development capabilities

Good Processing manufacturer capacity

Good parts supplier

Good After-sales teams

Send Inquiry to This Supplier

You May Also Like

-

Stacked Sludge DewateringNegotiableMOQ: 1 Set

-

Food Grade Liquid Mixing Tank Designed for Beverage and Dairy Production IndustriesNegotiableMOQ: 1 Unit

-

GYC Production Line of SoapNegotiableMOQ: 1

-

Multi Tube Vortex Mixer Laboratory MixerUS$ 753 - 753MOQ: 1 Piece

-

JHS2000 Mixer Double Movement Powder Mixer for Fine Powder, Superfine PowderUS$ 10,000 - 15,000MOQ: 1 Set

-

China Dry Mortar Zenamix Powder Mix Plant, Pigment Powder Mixing Machine for Making DetergentUS$ 800 - 1,500MOQ: 1 Set

-

Brightway Jet Mud Mixer of Solids Control SystemNegotiableMOQ: 1 Set

-

Fertilizer Manure Blender MixerUS$ 3,000 - 35,000MOQ: 1 Set

-

DJM Serie High Speed HomogenizerUS$ 1,000 - 5,000MOQ: 1 Unit

-

Industrial Horizontal Animal Ribbon Blender Dry Poultry Cattle Feed Mixer, Powder Mixer, Blender MixerUS$ 20,900 - 47,000MOQ: 1 Set