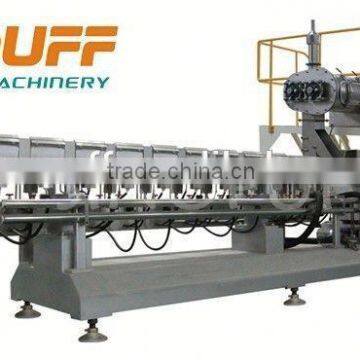

2d & 3d pallet food snack extruder processing line

Introduction:

The Puff Snack/Corn Snack/Extrusion Snack Process Line is using wheat flour, bean powder, tuber crops material, vegetable powder as the raw material; Via the effect of extrusion machine, to produce multiple types, variety shapes, crispy and tasty snack.Due to it is a profitable project with less investment, It won a lot of customers' favor and trust;

Production Process Line:

Raw material Mixer → Automatic Feeder → Twin Screw Extruder → Elevator → Dryer →Automatic Flavoring Line(Powder & Oil)

Basic Formula:

Corn Powder, Wheat Flour, Bean Powder, Rice Flour etc

Machine:

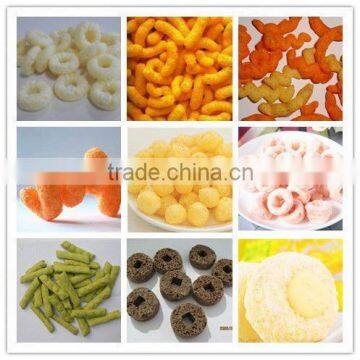

Application:

Machine Parameters:

| Model | Installed Power | Power Consumption | Capacity/Output | Dimension |

| SP65-II Twin Screw Extruder | 42.9kw | 30kw | 120-180kg/h | 3070x960x2050mm |

| SP65-III Twin Screw Extruder | 31.3kw | 22kw | 100-150kg/h | 2600x960x2000mm |

| SP70-III Twin Screw Extruder | 64.45kw | 40kw | 200-250kg/h | 3320x960x2100mm |

| SP75-III Twin Screw Extruder | 79.05kw | 50kw | 250-350kg/h | 4650x1100x2200mm |

| SP85-III Twin Screw Extruder | 97kw | 72kw | 350-500kg/h | 4800x1100x2300mm |

| SP52-II Twin Screw Extruder | 54.3kw | 40kw | 130-160kg/h | 4500x900x1820mm |

| SP75-II Twin Screw Extruder | 89.7kw | 67.3kw | 300-400kg/h | 5200x1100x2200mm |

| SP90-I Twin Screw Extruder | 161.3kw | 121kw | 600-800kg/h | 5800x1200x2500mm |

- Before Purchasing: We will provide professional technical project and sales consultation service to solve the customers' question and worried;

- During Production: Timely updates the machine status for customer to ensure delivery time, and quality

- After Production: Machine testing video and photos will be provided for inspection, if the customer can't come;

- Before & During Shipment: The machine will be cleaned and packaged before transportation; All the documents will be provided for the seller;

- Installation & Training: Providing professional and expert technical engineers to supply the training and installation service.

- After Sales Service; Dedicated department and engineers for providing the timely and efficient service when the clients' need, such as formula, parameters setting, and spare parts;

- Productive: Automated systems for controlled and consistent production on a continuous basis, easy and quick product changeover, automated start up, simple cleaning and maintenance procedures.

- Flexible Formula: Processing of a wide range of raw materials, such as corn, wheat, rice, potato, oat etc;

- Widly Appication: Easy adaptation to extend the range of products by changing the segments screw;

- Smart Control System: PLC Control of production to ensure optimized process parameters for each recipe;

- Advanced Die and Cutting system: This designs give processors an entirely new set of templates to create innovative shapes and sizes-Balls, animals, stars, rings, pillows, triangles, curls, chips, sticks, and also letters;

- All Machine will be cleaned and entirely wraped by plastic film to avoid any scratch;

- Extra Spare Parts, wires and tool box will be placed with the package;

- Deliver Department and sales will check the list to aviod any missing, and possible mistake;

- Good quality wooden cases to protecting the machine for long-tme shipment;

1 Where is your factory?

Jinan city, Shandong Province, China

2 What is your machine warranty?

1 year, main parts warranty time will be 2 or 3 years.

3 Do you supply spare parts?

Yes, we supply spare parts with reasonable price;

4 What can you provide for after sale service?

We can send engineers to your factory for installation and training if customers‘ required

5 If we show you our layout of factory, can you help to design the whole process line?

Yes, our experienced engineers and technical employee can help you to arrange the layout and installation of whole process line based on your real situation;

6 How can we contatc you if we meet problems during production?

Phone/email/wechat/whatsapp/Skype are all available.

7 If we have samples of new products, can you help to analysis and design the machine?

Yes, Our technical department can help to analysis, design and test the new products you offered.

What is hot?

Puff Snack/Corn Snack/Extrusion Snack 2D/3D Pellet, Fryums, Bugles Snack

↑ Point ↑ Point

American Popcorn/Caramel Popcorn Double Screw Extruder

↑ Point ↑ Point

Send Inquiry to This Supplier

You May Also Like

-

Commercial Fried Ice Cream Roll Machine With Single Square Pan and Double Pan and Material BarrowsNegotiableMOQ: 1 Set

-

Waffle Cone Maker Ice Cream Cone Machine Ice Cream Cone Production LineNegotiableMOQ: 1 Set

-

Small Scale Automatic Yogurt Making Machine Yogurt Production LineNegotiableMOQ: 1 Set

-

Hot Hydraulic Car Brake Fluid DOT3NegotiableMOQ: 1

-

LS Electric Motor ScooterNegotiableMOQ: 1

-

Precision CNC Turned PartsNegotiableMOQ: 1 Set

-

3 Way Speaker FilterNegotiableMOQ: 1

-

Food Kiosk Kebab Trailer, Hot Dog Cart Mobile Food, Food Cart Manufacturer PhilippinesUS$ 1,200 - 2,500MOQ: 1 Set

-

21 Power-driven Chip Twister MachineNegotiableMOQ: 1 Set

-

High Efficiency Potato Chips Cutting Machine for SaleUS$ 100 - 5,000MOQ: 1 Set