Home > Products > Yttria zirconia beads > 95% yttria stabilized zirconium oxide grinding media zirconia ceramic ball

95% yttria stabilized zirconium oxide grinding media zirconia ceramic ball

- 3000 Tonne / Tonnes per Month

- Qingdao

- T/T Credit Card

You May Like

-

yttrium stabilized zirconia beads superfine abrasing media

-

High Quality 15/20/30mm Y2O3 stable Zirconia Grinding Media for ball mill

-

TZP grinding ball zircona micro grinding media

-

High quality Zirconia Grinding Media ball

-

yttrium oxide stabilized zirconia ball grinding media

-

Yttria stabilised zirconium beads griniding media

Product Details

| Place of Origin | Shandong, China | Type | Ceramic Balls | |

| Application | Structure Ceramic | Material | Zirconia Ceramic | |

| Brand Name | Qirui Tech |

Product Description

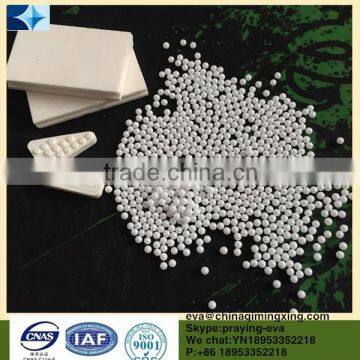

95% yttria stabilized zirconium oxide grinding media zirconia ceramic ball

TZP grinding media

1.High strength, high fracture toughness, wear resistant, high hardness, corrosion reistance, ultra smooth surface. easy clean, reduce the intermal friction between the beads and improve the material flow efficiency.

2. Good spherical degree

3. Lower costs for its long using life.

Application: Material for grinding and dispersed, structural ceramics, electronic ceramics, refractory ceramics, magnetic material, zirconia silicate, food, medical, high grade color glaze and mechinical equipments, etc.

Available size: Sphere(Diameter):0.3mm,0.4-0.6mm,0.8mm,1mm,1.2mm,1.4mm,2.0mm,3.0mm, 5mm, 6.5mm,7.0mm,,8.5mm,10mm,12mm,15mm,20mm,25mm,30mm etc

Cylinder(Dimater):3x3mm,5x5mm,7x7mm,7x9mm,10x10mm,12.7x12.7mm,15x15mm,20x20mm etc

Advantages:

Compareed with the trational grinding medium, such as alumina balls, zirconium silicate balls, steel ball and glss beads, the zirconia grinding medium(Y-TZP grinding medium) has high density, high hardness and high fracture toughness factures, which provide it higher grinding efficiency than the traditional grinding medium, it can protect materials from pollution and guard against chemical corrosion.

Technical Datas:

Name | Unite | Sphere Series Parameter |

ZrO2 | % | 94.6 |

Y2O3 | % | 5.4 |

Al2O3 | % | <0.3 |

SiO2 | % | <0.02 |

Fe2O3 | % | <0.01 |

Na2O | % | <0.02 |

Density | g/cm³ | 5.95-6.0 |

Hardness(HV) | GPa | >11 |

Bending Strength | MPa | >1150 |

Fracture Toughness | Mpa.m0.5 | 7-10 |

Grain size | μm | <0.5 |

Modulus Elasticity | GPa | 205 |

Abrasion | ppm/h | <5 |

Thermal conductivity | W/(m.k) | 3 |

Thermal Expansion Coefficient | X10-6/k | 11 |

Crush Strength | KN | ≥20(Ø7 for example) |

Filling Density | Kg/L | 3.5(Ø5 for example) |

Appearance | / | Shining,white, no porous, no crackle |

Products pictures

Production process:

Item name: | 95% yttria stabilized zirconium oxide grinding media zirconia ceramic ball |

Origin: | China |

Type: | Rolling/Dry Isostatic pressing |

Packaging: | 25kg/barrel, 1ton/wooden/plastic pallet |

MOQ: | 100kgs |

Delivery time: | 10-15days against the deposit |

Payment term: | T/T 30% in advance, the balance against the copy of B/L Or L/C at sight |

Sample time: | Available in any time |

1. All products are 100% tested before the shipment, to ensure the good quality.

2. We're responsible for the claims caused by the quality.

Feel free to contact us: chinaqimingxing(at)gmail(dot)com and you will get the best ceramic beads and balls with excellent service, facilities and know-how of world producers.

We offer a full range of ceramic balls. Different types suitable for different applications according to customer requirements differ in chemical composition, the density and size of single fractions.

These balls are used in the most branches of industry.

1. What’s your product range?

- Y-TZP grinding media

- Microcrystalline alumina grinding media(92%,75%,60%,49%Al2O3 content)

- ZTA Zirconia alumina toughened grinding media

- Ce-TZP grinding media

- Zirconium silicate grinding media

- Wear resistant Alumina ceramic liner

2. What information should I offer to you if I want to know the quotation?

- Size of the grinding media;

- Usage of the grinding media;

- Quantities you need;

- The properties of the grinding media ;

- Any requirements for the delivery time;

- Destination.

3. Can I get the sample for free?

- Free samples can be supplied in any time.

4.How long does it take to delivery time?

If stock is sufficient,within 3 days.

If no stock,it need 7-10days.

5. The annual Output?

-14,000tons

6.What is the MOQ?

- 10kgs

eva(at)

praying-eva

+86-18953352218

Contact Us

- Zibo Qimingxing New Material Co., Ltd.

- Contact nameHong Qin Chat Now

- Phone0086-533-3591856

- AddressMiddle of Industrial Road, Hi-tech Development Area, Zibo, Shandong, China, Zibo, Shandong

Product Categories

New Products

-

Zirconia milling beads ceramic beads for superfine grinding

-

wear resistant ytz grinding ball for sand mills

-

Superfine grinding media ceramic micro-milling media

-

ceramic micro milling ball zirconium oxide grinding ball

-

Zirconium oxide ceramic ball for grinding

-

Ceramic milling balls zirconia grinding media 95% ZrO2

-

Yttria zirconia ceramic micro milling media grinding beads

-

Superfine grinding ceramic beads micro milling media

-

zirconium oxide grinding bead for mining

-

ceramic products zirconia beads grinding media

-

ceramic beads type tzp grinding media

-

yttria stabilized zirconium media 10mm zirconia grinding bead

-

Yttria stabilized zirconium oxide dispersion media

-

zirconia bead ytz ball mill grinding media

-

zirconia bead for grinding or milling

-

zirconium beads grind ball zirconia grinding media

-

wet grinding zirconia ball for ball mill

-

yttrium stabilized zirconium bead ceramic grinding medium

-

Ceramic micro ball zirconia ceramic grinding balls

-

95% ceramic grinding balls zirconia grinding media

-

zirconia sand mills grinding media ceramic bead

-

Ceramic milling balls zirconia grinding media

-

wet grinding zirconia ball grinding ball for sand mills

-

zirconium oxide beads grind ball ceramic grinding media

Popular Searches

- ceramic ball

- alumina ceramic

- Alumina Ceramic Ball

- industrial ball

- ceramic filter

- ceramic substrate

- Ceramic Foam Filter

- Electrical Ceramics

- ceramic sheet

- industrial ceramic

- alumina tube

- aluminium nitride

- ceramic parts

- ceramic insulation

- zirconia ceramic

- Cordierite Ceramic

- Aluminum Nitride Ceramic

- Boron Nitride Ceramic

- Ceramic Part

- Alumina Ceramic Tube

- pottery

- resistance tube

- ceramic alumina grinding balls

- nitride

- Ceramic Rod

- ceramic tube

- advanced ceramic

- alumina pipe

- ceramic bushing

- alumina ceramic ring

Recommended Products

- RSiC grinded batts,ReSiC kiln shelves, recrystallized silicon carbide ceramic slabs, RSiC setter plates

- ReSiC burner nozzles, recrystallized silicon carbide ceramic burner tubes, gas burner

- ReSiC burner nozzles, recrystallized silicon carbide ceramic burner tubes, gas burner

- RBSiC silicon carbide ceramic burner tubes, SiSiC burner nozzles, gas burner protetive tubes

- SiSiC rollers, silicon carbide ceramic tubes, RBSiC roller

- silicon nitride thermocouple protection tubes, Sialon sheath, Si3N4 stalk tubes, heating protective tubes

- RSiC batts,ReSiC kiln shelves, recrystallized silicon carbide ceramic slabs, RSiC setter plates

- RSiC round plates, ReSiC kiln shelves, recrystallized silicon carbide ceramic slabs, RSiC setters

- nitrided bonded silicon carbide ceramic slabs, advanced NSiC kiln shelves, NSiC setters, NSiC plain batts, SiC plates,

- SiSiC beams, reaction bonded silicon carbide kiln furniture system, RBSiC loading beams

- advanced NSiC radiant tubes, NSiC heating protective tubes, nitride bonded silicon carbide ceramic tubes,

- SiSiC radiant tubes, silicon carbide ceramic tubes, RBSiC protective tubes

Find Similar Products By Category

- Minerals & Metallurgy > Ceramics

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Hong Qin

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Hong Qin

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile