Cast Stainless Steel Cut Wire Shot 1.0mm for Shot Blasting Machine

1)Bonzer Stainless steel cut-wire shot is being used in an increasing number of important applications where ferrous contamination in blasting stainless steel, titanium, aluminum, or other non ferrous work objects could be harmful.

We offer shots in different grades like SUS304, SUS316, SUS202, SUS410, SUS430 according to customers’ need.

It is also used in peening these metals (stainless steel, titanium, brass or aluminum) in work objects that are subject to stress corrosion cracking.

2)Size: 0.2mm,0.3mm,0.4mm, 0.5mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm

3)Appearance:

As-Cut: Due to its sharp edge, it works good for cleaning where speed of cleaning is critical and somewhat rough finish is acceptable.But as-cut shot is not advisable to use for peening operation.

Conditioned: Cut shots which are rounded off are used more in the shot peening process, also in different industries such as automotive industry, aerospace industry, shipping industry.

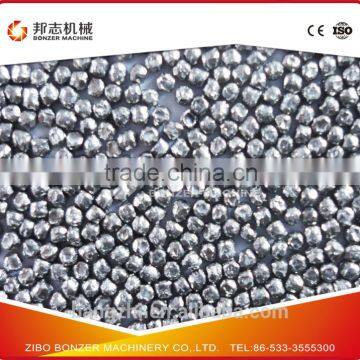

4)Product Photos

5)Technical Parameter

| Product | Stainless Steel Cut Wire Shot | |

|

Chemical Composition |

C | ≤0.12% |

| Mn | ≤2.00% | |

| Si | ≤1.00% | |

| S | ≤0.03% |

|

| P | ≤0.035% |

|

| Cr | 17-19% |

|

| Ni | 7-10% | |

Hardness |

HRC 41-59(388-509HV) |

|

| Appearance |

Spherical / cylindrical |

|

| Grain Size | 0.2mm-1.2mm | |

| Cycling Usage Counter | 5000-8000times | |

| Microstructure | Ferrite /Austenite |

|

| Density | ≥ 7.4g/cm3 | |

6)The advantage

Cut wire does not fracture or breakdown during use because it is solid. As a result several positive things occur:

1.Stainless cut wire shot has a significantly longer useful life than cast steel shot and grit

2.Dust generation is significantly lower so blasting operations are much cleaner

3.Stainless cut wire produces excellent results because of its uniformity and strength

4.It will make you a "Greener" organization because disposal of spent media will be significantly reduced

5.No ferrous contamination to non ferrous castings or work objects

2) Low breakage, low wear, little dust;

3) Low wear of the equipment, long life of accessory;

4) Reduce dedusting system load, lengthen usage time of dedusting equipments.

Deflashing, deburring and surface finishing of aluminium castings and die castings without imparting ferrous particles and dust onto the surface that can discolour.

Shot peening of non ferrous components that cannot tolerate any ferrous contamination. Shot peening repeatability is improved due to durability of the particles.

---- Remove sand and rust on iron casts,steel casts,forgings,heat treatment pieces,metal panel etc.

G2 Double Conditioned ---- used in all kinds of steel plate pretreatment,castings,standard components,stamped parts,stainless steel parts and other work pieces, which can get the good shot basting results of removing sand and rust,surface descaling,smooth and tidiness.

G3 Spherical Conditioned---- used in many feild of blastig cleaning and shot peening and perform the tasks of surface cleaning,removing coating and corrosion,olidifying the surface of work pieces.

1.Payment Term

1.T/T,30% deposit, 70% before shipment

2.L/C irrevocable LC at sight

2.MOQ

500KGS

3.Delivery Time

15 days after received your deposit

4.Free Sample

200g

5.Relative Standards

SAE,ISO9001 and ISO1004

Send Inquiry to This Supplier

You May Also Like

-

Finishing Media Brown CorundumNegotiableMOQ: 1 Ton

-

Good Performance CBN Abrasive Sanding Belts for Steel ,alloyNegotiableMOQ: 50 Pieces

-

Free Sample Brown Fused Alumina / BFA for SandblastingUS$ 200 - 680MOQ: 1 Ton

-

Sanding Screen RollUS$ 0.1 - 10MOQ: 10000 Pieces

-

YDF-SS-110 Low Price Cast Steel Shot for Polish and GrindingUS$ 1 - 1,000MOQ: 1 Ton

-

Artificial DiamondNegotiableMOQ: 1

-

2016 Products Foshan Abrasive Manufacturer For Glazed Polishing Vitrified TileUS$ 3 - 4.5MOQ: 24 Pieces

-

Industrial Stainless Steel Sanding Flapper WheelsUS$ 0.12 - 0.48MOQ: 5000 Pieces

-

3mm Shank Pink Mounted StonesNegotiableMOQ: 1

-

Low Broken / High Wear- Resistant Steel Cut Wire ShotUS$ 650 - 850MOQ: 10 Metric Tons