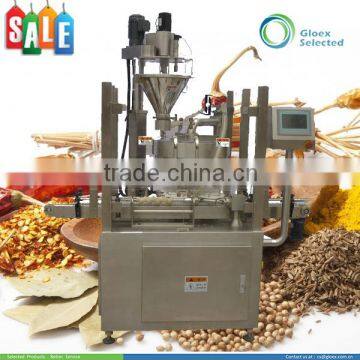

Rotary Type Easy Operation High Speed Flour Automatic Packing Machine

Rotary Type easy operation high speed flour automatic packing machine

These series machines are applicable for packing powder, small granule in form of small bottle, with different type of capping or sealing device is capable to form a production line, the detail application description as following table:

Issue | Application Description |

Applicable Products | Suitable for powder or small granule dosing and filling. Such as herb & spice powder, medical powder, condiment powder, dextrose, nutrition powder additive etc |

Applicable Containers | small bottles with size : Diameter 26-60mm; Height 40-200mm |

Following are the reference style of packaging

Standard Features

• Suitable for powder or small granule dosing and filling in form of small bottles

• Filling by container rotating , achieve high speed filling

• Replaceable small container adaption components, to adapt to different shape and small size bottles

• PLC &Touch screen HMI control enable easy operation parameter setting up and troubleshooting

• Configure with servo motors to drive dosing auger and the rotary plate, to achieve high dosing accuracy and speed.

• Container vibrating device, to assure the density of filling

• No container no filling protection, keep environment clean

• Height adjustable devices, to adapt different height of the container

• Quick assembly hopper could be cleaned easily without tools

• Transparent hopper configuration, easy for operation monitoring

• Storing 10 groups of technical parameter for the different products, convenient for product changing

• By simply changing the auger parts, suitable for filling material from super fine powder to granule materials.

Catalogue/1D-xxxxx | 2A-6 |

Container Dimension-‘mm | 1) Diameter 26-60 2) Height 40-200 |

Filling Range ‘g | 5-100 |

Filling Accuracy | 1) 5 - 10g,<=±3%; 2) 10 - 100g,<=±2%; |

Filling Speed -cans/min | 20-120 |

Hopper Volume-Liter | 25-Standard |

Power Requirement | AC208-415V 50/60Hz |

Power Consumption-KW | 1.32 |

Compress Air Required-Mpa | 0.6 |

Compress Air Consumption-m3/min | 0.03 |

Approximate Weight -kg | 400 |

Dimension ( ‘mm ) | 1800*1050*1610 |

Our Partners

Except for the design of the machine, the key components configuration will determine the quality of the machine or system, below is the shortlist configuration of the key components:

No | Components | Material / Short List |

1 | Products Touching Parts | Made of Stainless Steel 304 as the standard configuration, 316,316L can be equipped subject to the client’s customization. |

2 | Frame & Body | Made of Stainless Steel 304 or Carbon Steel at buyer’s option |

3 | Man-Machine Interface | Weinview, Schneider |

4 | Stepper/Servo Motor | Teco, Delta,Panasonic |

5 | Programmable Logic Controller | Fatek |

6 | Electric Components | Schneider,ARK |

7 | Sensors | Autonics |

8 | DC Relay | Omron |

9 | Contactor and Other Relay | Chint |

10 | Stirring Motor | Wanshsin |

11 | Pneumatic Components | Airtac |

12 | Load Cell | Zemic |

Compare with others, this machine is more focusing on the details, and these details determine the performance, with its advantage as following

Compare with others, this machine is more focusing on the details, and these details determine the performance, with its advantage as following

a) 2 Servo motors driving, more accurate dosing, faster speed

b) Transparent hopper, operation visible

c) Quick assembly hopper, easy for cleaning

d) Height adjustable to adapt different container

e) Auger changeable enable different product dosing and filling

f) High speed filling design, filling by rotating

g) Vibrating while filling , ensure the filling density

This pouch packaging machine, with CE Approval, running at hundreds of proven projects, stable operating under excellent performance

Rotary Type new electric spice rotary filling machine

In order to form a production line, the corresponding capping, seaming, sealing or labeling machines are necessary accessories,click for following links to get more inofrmation

- Capping, Sealing or Seaming Machinies

- Labeling Machine

If you wanto pack granule or powder in form of pouches, stick, or big bags , followmg link will guide you know more

In ordr to enable you understand our products conveniently , following documents are available, but not limited, to be provided upon the stage of purchasing

No | Document | Code | Description |

1 | Products Selection Guide | SG | To select or customize the suitable products for the clients upon the feedback of Selection Guide, which include project background, parameters and other client’s requirement |

2 | Products Profile | PP | To enable the clients understand the overview of the products, Covers sections of Basic Features, Application, Construction, Typical Products, Approvals, and Optional Features |

3 | Installation Instruction | IN | To explain the step of installation of the equipment, and include commissioning instruction as well |

4 | User Manual | UM | To cover the content of Operation & Maintenance and Trouble Shooting |

Rotary Type new electric spice rotary filling machine

Customization Philosophy

The product demonstrating may not perfectly meet your requirements, our philosophy is to customize your real need, To minimizing idle capacity and function. To supply you performance and cost balanced products. Following are the factors shall be taken into account during customization:

- Filling Products

- Container to be filled, type and specification.

- Capacity requirement

- Automation requirement

- Protection requirement

- Other specific requirement

Selection Guide

Selection Guides are available for circulation, contact us to get products selection and customization support.

Statement

- The pictures demonstrating in this profile represent products of range, and subject to the newest or customized design

- Due to the huge number of documentation updating, the data indicated in this profile may not be updated timely, Please contact with our customer service for newest version.

- The features or functions appear in this profile subject to the additional description of quotation

Send Inquiry to This Supplier

You May Also Like

-

800kg 1000kg Bulk Bag Bagger Resin Particles Plastic Pellets FIBC Bag Filling Packaging Jumbo Bag Packing MachineUS$ 1 - 48000MOQ: 1 Set

-

Automatic Spice Powder Grinding Machines Salt and Peeper Grinder Nut Grinder Machine for Food ProcessingUS$ 620 - 1060MOQ: 1 Set

-

Stainless Steel 304 Beer Bottle Filling Equipment Electric 380V 50Hz 3 PhaseNegotiableMOQ: 1 Set

-

GNEYOND Protein Powder Filling and Seaming Line Milk Powder Tin Can Filling Sealing MachineNegotiableMOQ: 1 Set

-

Pyramid Tea Bag Packing Machine|Tea Sachet Packaging MachineNegotiableMOQ: 1 Set

-

China Small Beverage Bottle Wrapping Machine /juice Bottle Packing Machine/shrink Packing MachineUS$ 4,000 - 10,000MOQ: 1 Set

-

Semi Automatic FIBC Filling Systems Manual Bag Breaker ,fibc LoaderUS$ 1 - 48000MOQ: 1 Set

-

Big Bags 1 Ton Jumbo Bag Powder Granule Packaging Machine FIBC Weighing Filling StationUS$ 1 - 48000MOQ: 1 Set

-

Weighing FIBC Bulk Jumbo 500kg 1000kg Ton Bulk Bag Automatic Filling Packaging Machine Big Bag Packing Machine Ton Bag SystemUS$ 1 - 48000MOQ: 1 Set

-

Precision Weighing Unit Big Bag Packaging Machine Automatic FIBC Packer 1000kg Bag Filling MachineUS$ 1 - 48000MOQ: 1 Set