Shuangsheng 90T Injection Molding Machine

Export 90T injection molding machine

Main parameters of 90T plastic injection machine as below;

| Items | Parameter | Unit | Parameter Value (SSF900) | ||

| Injection Unit | Screw diameter | mm | A | B | C |

| 32 | 35 | 38 | |||

| Screw L/D ratio | L/D | 24.8 | 22 | 20 | |

| shot volumn (theoretical) | Cm3 | 112 | 134 | 158 | |

| injection weight(PS) | g | 102 | 122 | 144 | |

| plasticizing capacity | g/s | 10.5 | 11.6 | 13 | |

| injection rate | g/s | 90 | 107 | 126 | |

| injection pressure | Mpa | 208 | 174 | 148 | |

| screw speed | rmp | 220 | |||

| Clamping unit | clamp force | KN | 900 | ||

| open stroke | mm | 290 | |||

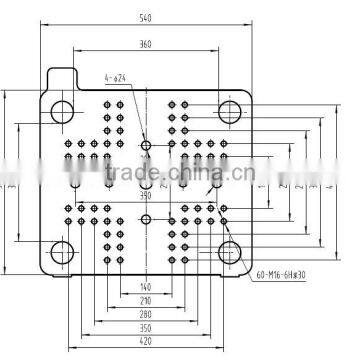

| space between bars (W*H) | mm | 360*320 | |||

| max mould height | mm | 380 | |||

| min mould height | mm | 150 | |||

| ejector stroke | mm | 80 | |||

| ejector force | KN | 31 | |||

| ejector number | PC | 5 | |||

| mould align diameter | mm | 125 | |||

| Others | max pump pressure | Mpa | 16 | ||

| pump motor power | KW | 9 | |||

| heating power | KW | 6 | |||

| machine dimension | m | 4*1.27*1.75 | |||

| machine weight | T | 2.9 | |||

| oil tank capacity | L | 150 | |||

Standard features;

Double-cylinder balanced injection system;

Multi-stage pressure &speed injection;

Back pressure adjustment device;

Low pressure mold protection;

Single hydraulic core pulling and inserting;

Multiple hydraulic ejector knock-out;

Mechanical, electrical safety device;

Auto lubrication system;

Hydraulic pressure full proportional control;

Computer control system;

Molding data memory system;

Automatic mould adjust function.

Optional auxiliary;

Robot system

Hopper dryer

Auto loader

Hopper Magnet

Mold clamps

Water cooler

Plastic dehumidizer

Mold temperature controller

Oil temperature controller

Oil bypass filter

Spare parts;

1.Nozzle

2.Lubricate oil

3.Seal rings(5pcs)

4. Tool box

5. Other tools such as spanner, straight screwdrivers;

6. Crash pad

Clamping unit

Five-point inward moving toggle system ensure high rigidity and precision for mold clamping and also reducing stress and stain effects;

The moving platen is fitted with adjustable slide support system to improve platen parallelism and provide better tie bar and mould protection and lengthen the working lifetime.

Injection unit

A wide variety of screws are available for different polymer processing requirements. Special engineering materials are used to manufacture the screws to ensure optimal quality and processing life;

The injection unit incorporates a dual-pillar supporting system with balanced twin cylinder injection unit for evenly distributed force and rapid screw motion;

Nozzle alignment is provided using a simple mechanism with fine adjustment for accurate centering;

High quality nitride or chrome plated alloy screw with a nitrogen-treated barrel provided anti corrossion with high wear resistance for an extended working life.

Electrical and hydraulic components;

Major hydraulic components and seals are sourced from world famous manufacturers providing high reliability and interchangeability.

Controller is from Techmation, with multiple language for selection, of including but not limited English, Spanish,Turkish,Persian,russia and etc.

Lubrication system;

The toggle system uses oil-sleeve bushes lubricated by an automatically control central lubrication unit which provides excellent lubrication quality to all points and extends the clamping unit working life.

There are 2 type of lubrication agent, one is lubrication grease, the other is lubrication oil, per customer's final products requirements, medical parts prefer to use lubrication oil to avoid any contamination.

Motors and pumps;

We have 2 series injection molding machine, one is fixed pump, the other is servo motor.

Fixed pump machine is a traditional machine enjoys the features of stable, servo motor enjoys the advantanges of energy saving.

Low noise, below 78db, servo motor almost has no noice when no movement of machine.

Plastic parts that can be made but not limited

Agent wanted

In order to bring our machines to more customer worldwidely, we are sincerely to invite distributors to get exclusive agency agreement from us.

We have signed agency agreements with distributors in Argentina, Denmark,Poland,Russia,Turkey,Colombia.

Welcome your join-in, and we respect all our agents and will protect their market.

Our Services;

If you have any query about our injection molding machine, just contact me at any time

Mobile photo:+8613806673276(whats app&we chat ID)

QQ:1159033100

Send Inquiry to This Supplier

You May Also Like

-

NEW Automatic Plastic Plate Making MachineUS$ 1,500 - 20,000MOQ: 1 Set

-

Top Performance XPS Foamed Board Making MachineUS$ 1,000 - 50,000MOQ: 1 Set

-

Factory Direct Soccer Wear Sports Game Service Organizations ServingNegotiableMOQ: 1 Set

-

Clear Moisture-proof Laminating Roll Film With Strong Bonding Strength For Credit CardsUS$ 4 - 5MOQ: 1 Set

-

Heat-resistant Customed OEM Non-toxic PVC Transparent Binding Cover For Stationery PackingNegotiableMOQ: 1 Set

-

High Quality Vacuum Forming MachineUS$ 2,899 - 18,999MOQ: 1 Set

-

Guangzhou High Point 30 Year Experience Cornice Moulding Eps Vacuum Forming Machine Best ServiceUS$ 3,130 - 13,350MOQ: 1 Set

-

2016 Hot Sale !pvc pp Vacuum Forming MachineUS$ 3,900 - 5,400MOQ: 1 Set

-

Fully Automatic Plastic Cup Thermoforming MachineUS$ 3,000 - 65,000MOQ: 1 Set

-

Automatic Foam EPS Plastic Cups Making MachineUS$ 9,000 - 290,000MOQ: 1 Set