Fly Ash Pipelines Ceramic Lining in Coal Fired Power Station of Kingcera

Specifications

1. highly abrasion resistant2. highly temperature resistant

3. corrostion resistant

4. good thermal shock resistant

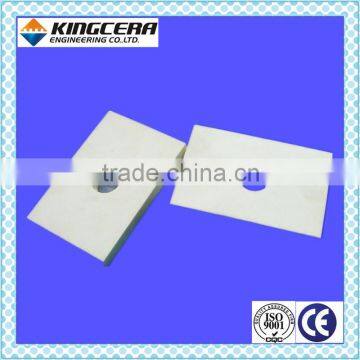

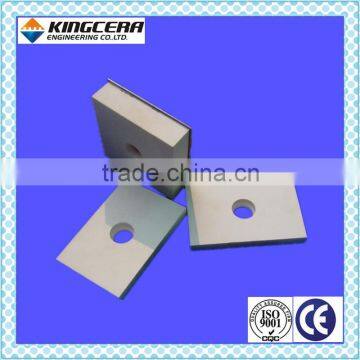

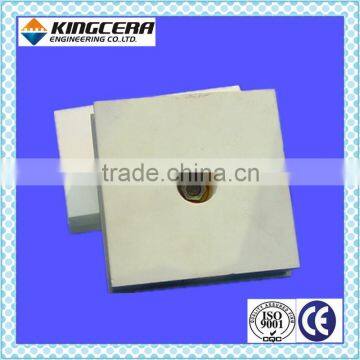

Direct bonding ceramic

Kingcare offer optimized wear protection for plant components and pipe systems.

why wear protection? ---reduce cost and avoid downtime

Specification:

| Item | Index |

| Content of alumina | ≥ 95% |

| Denisty | ≥ 3.5g/cm3 |

| Rockwell hardness | ≥ 80 HRA |

| Impact strength | ≥ 850 Mpa |

| Fracture toughness | ≥ 4.8 Mpa . m½ |

| Bending strenght | ≥290 Mpa |

| Thermal conductivity | 20 W/ M. K |

| Thermal expansion coefficient | 7.2 * 10-6M/M.K |

Product strucure:

Kingcera Alumina ceramic is directly affixed on the steel plate of inner wall of equipment by high temperature resistant inorganic bond and forms a firm wear resistant layer after heating solidification. Ther product is applicable for the air (wind) powder feeding, and can be used in a high temperature in long term without aging and peeling.

Clear advantages:

--- long lifetime

--- maintenance free operation

--- no operation interuption

--- no production losses

--- no contaminaiton of conveyed mataterial due to abrasion, mixture or oxidation

--- physiologically harmless, suiable for food products

--- smooth surface to achieve good flowability and to aviod plugs

--- reduced pressure losses and lower energy cost

Services rendered for many branches of industry:

Coal fired power plant Iron and steel Industry

Cement Industy Further Industries

Installation on site

Mechanicl fixings

Application examples:

Here is a list of typical abrasion problem components:

-- ash pipeline -- mixer troughs

-- belt discharge chutes -- pipe bends

-- bunker spirals -- pipes

-- bunkers -- pneumatic backfill lines

-- channels -- priling tower bottoms

-- chutes -- pulpers

-- circulating air separators -- receivers

-- continuous flow conveyors -- screw conveyor troughs

-- cyclones -- separators

-- dissolving tanks -- setting basins

-- drying sections -- shaft spiral

-- dust collectingequipment -- sifters

-- dust collecting pipes -- silos

-- fans -- sinter troughs

-- flue gas ducts -- tailing lines

-- flumes -- tanks

-- gravele lrease tunnels -- thickners

-- hoppers of rotary dryers -- tubular chain conveyors

-- hydro-cyclones -- turbo separators

-- launders -- vibrating troughs

-- washing drums

Send Inquiry to This Supplier

You May Also Like

-

Medical Devices & Equipments , Dental Equipments CNC Milling Services With Aluminum AlloyNegotiableMOQ: 1 Kilogram

-

Aluminum Metal Stamping Parts Performance Punched Parts For Electricity EquipmentNegotiableMOQ: 1 Kilogram

-

Silver Industrial Aluminium Sliding Door Profiles Aluminum Extrusion FabricationNegotiableMOQ: 1 Kilogram

-

Ceramic BallUS$ 0.86 - 3.65MOQ: 100 Kilograms

-

Lock-nuts Splicing Bolt Connector With Torque Wrench for Connecting RebarsNegotiableMOQ: 1 Kilogram

-

Custom Made Electric Motor Magnet NdFeB Ring Magnet For MicroMotor / MRIUS$ 0.01 - 2MOQ: 1 Kilogram

-

Passive Door Switch , Elevator Component / Parts , PB143NegotiableMOQ: 1 Kilogram

-

Brass / Aluminum CNC Turning Parts Services For Led Lamp NF UNI JPI 0.006mm ToloranceNegotiableMOQ: 1 Kilogram

-

Sell CenospheresNegotiableMOQ: 1 Kilogram

-

Modern Style Ceramic Flower VaseUS$ 1 - 2MOQ: 1000 Pieces