Ni-Based Super-alloy High Pressure Hydro-thermal Reactor 1100C, Optional Volume 65ml & 100ml

Ni-Based Super-alloy High Pressure Hydro-thermal Reactor 1100C, Optional Volume 65ml & 100ml

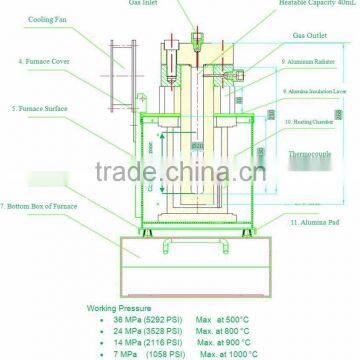

RC-Ni is reactor made of Ni-Base Super-alloy, which has excellent creep strength and anti-oxidation. It can reach 1100 °C with a pressure up to 4Mpa under oxygen or inert gased. It is an ideal tool for preparing advanced material by hydro-thermal method, especially heat treat sample under high oxygen pressure. A solenoid valve is installed on the flange allows auto-pressure relief control. Temp. Control and Pressure Real-time Monitoring software is also included.

Specification:

|

|

Working Voltage |

|

Pressure Vessel |

|

|

Reactor Capacity & Dimensions |

|

|

Working Temperature & Controller |

|

Working Pressure |

|

|

|

Accessories |

|

Display of the high pressure reactor:

Send Inquiry to This Supplier

You May Also Like

-

Biological Products and Preparation VesselNegotiableMOQ: 1 Set

-

Industrial Laundry Bar Soap Toilet Bath Soap Plodder Extruder Printer Forming Making Machine Production LineNegotiableMOQ: 1

-

Magnetic Stirring KettleUS$ 1100 - 1800MOQ: 1 Piece

-

Soil and Concrete Lab EquipmentUS$ 500 - 1,500MOQ: 1 Set

-

PE Machinery Water Tanks , Plastic Tank, Fuel TankUS$ 20 - 90MOQ: 1

-

Active Lime Rotary Kiln Burning Plant for SaleUS$ 1,000,000 - 2,000,000MOQ: 1 Set

-

Upender Machine for Organic Fertilzier Fermentation (CE)US$ 1,500 - 60,000MOQ: 1 Set

-

Microwave Supercritical Extraction EquipmentUS$ 2,900 - 5,000MOQ: 1 Set

-

Soap Making Machine/toilet Soap Making Machine/laundry Soap Making MachineUS$ 10,000 - 20,000MOQ: 1 Set

-

Disk Granulating Machine for Ceramic SandUS$ 1,000 - 20,000MOQ: 1 Set