Latest Technology Soybean Oil Refinery Production Equipment

1-600T/D soyban oil refining machine/plant famous brand

1.Introduction

(1) Purpose: Oil refining is according to the different usage and requirements, utilizing the physical methods and chemical processes to get rid of the harmful impurities and needless substance

in the crude oil, getting standard oil.

It is suitable for refining various crude vegetable oil, such as sunflower seed oil, tea seed oil, groundnut oil, cottonseed oil, palm oil, rice bran oil, soybean oil, corn oil and palm oil, etc.

(2) main parts: refining pot , decoloration pot ,deodorization pot , oil pumps and other parts

(3) Advantage: a . After refining the impurity of oil must be less than 0.2% ;

b. Recycling system save power and money ;

c. Lower oil waste.

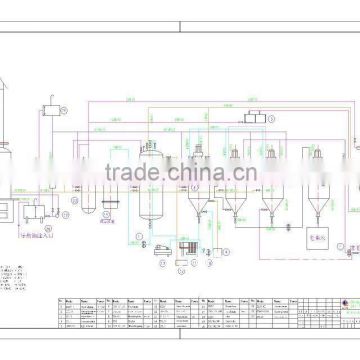

2.Working process

(2)Pump refined oil into decoloring tank. When it is up to 90-110°c after one hour's heating,

add clay into tank for 20min's processing. Then separate clay and oil with filter.

(3)Put discolored oil into deodorization tank with vacuum pump. Heat and process with steam for odor removal.

After filtering, you will get final oil product.

3.Functions of main parts

(1) Refining section: used to P-acid de-gumming, alkali refining de-acid and water rinsing.

(2) Decoloring section: used to remove off pigments, bleaching oils and grease dehydrate.

(3) Deodorizing section: to remove off the odor components in oil.

(4) Dewax: used to remove off the wax in the oil, in order to get the high quality oil.

(5) Heat-transfer oil stove: supply each device production needing heat energy, temperature reach above 280°C.

(6) Steam generator: produce the needing steam for de-odoring and distillation.

(7) Vacuum pump: supply needing vacuum for dehydrate, de-color, de-odor. Vacuum degree can reach above 755mm Hg.

(8) Press filter: filter clay, filter out clear oil.

(9) Air compressor: blow dry bleached clay, blow empty the leftover oil in the press filter.

4.Professional Advice

Please kindly inform us your required daily capacity, treated quantity, raw material, covering space and related data,

so that we can make flow chart production line for you as your requirement. we will stand at your point to suggest low cost and suitable production line for you.

Sincerely want to cooperate with you.

Besides refining equipment, our company also provide high quality prepressing equipment and leaching/extraction equipment with

which the you can prepress the raw material and get the oil in the cake.

Welcome to contact us.

Customers pictures :

Send Inquiry to This Supplier

You May Also Like

-

Silymarin Milk Thistle Extract FactoryNegotiableMOQ: 1 Metric Ton

-

CHINA Factory Distiller Small Extractor Steam Essential Oil Distillation Machine Essential Oil Making MachineNegotiableMOQ: 1

-

Cumin Seed PowderUS$ 4.79 - 4.79MOQ: 100 Kilograms

-

Portable Grouted Splice CouplerNegotiableMOQ: 1

-

New Tight-fitting Sportswear the Diving Suit Digital Print CustomNegotiableMOQ: 1

-

Sell Soybean IsoflavonesNegotiableMOQ: 1

-

Fuzz Cashmere Comb For Cashmere Sweaters With High QualityUS$ 0.6 - 0.8MOQ: 5000 Pieces

-

Garlic Oil, Garlic Seed Oil, Pure Garlic Oil AllicinUS$ 4.5 - 5.5MOQ: 1000 Kilograms

-

High Quality Hot Sell Senna PowderNegotiableMOQ: 200 Kilograms

-

Portulaca Oleracea ExtractNegotiableMOQ: 1 Kilogram